Comet Technologies: Dragonfly 3D World image processing software

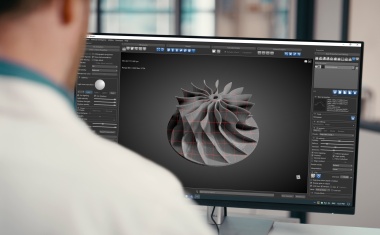

Dragonfly 3D World is an AI-enabled image processing and analysis platform for industrial inspection workflows.

Dragonfly 3D World is an AI-enabled image processing and analysis platform for industrial inspection workflows.

Visionkit is an AI platform for optical quality inspection – built to handle growing product complexity and skilled labor shortages.

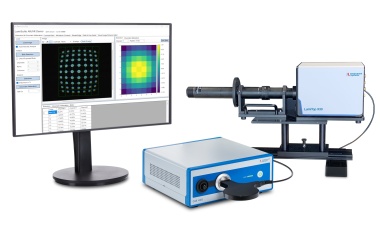

The Lumitop X30 AR, an imaging color measurement system from Instrument Systems, was developed for near-eye displays.

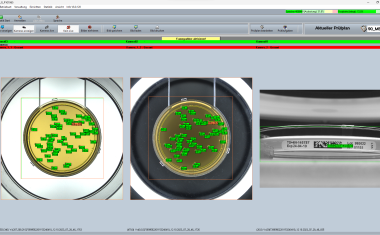

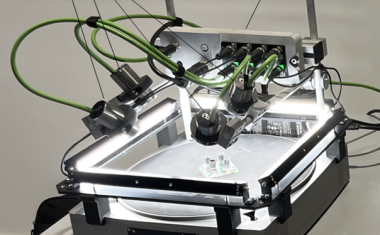

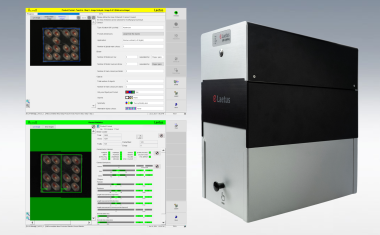

VMT is modernizing pharmaceutical hygiene monitoring, replacing error-prone, time- and resource-intensive manual processes with the fully automatic evaluation of thousands of contact/settle plates (Ø 55/90 mm).

Improving from the 5,000 MB/s camera bandwidth, the new Coaxlink QSFP28 surges beyond this limit, using the latest optical interfaces and Vision Standard IP-Cores to offer 12,500 MB/s camera bandwidth.

With the FSM:GO IMX900 in a compact industrial housing, Framos presents a solution for industrial embedded vision that is geared toward current developments in robotics and automation.

The camera platform combines an M30x60 design, integrated optics, single-cable technology, and AI-enabled processing—supplemented by the self-configuring Camera Master with 5GigE and IO-Link.

Compass supports quality control in industrial X-ray inspection. The AI assistance system offers functions for semi-automated to fully automated defect detection (ADR) in accordance with ASTM E3327.

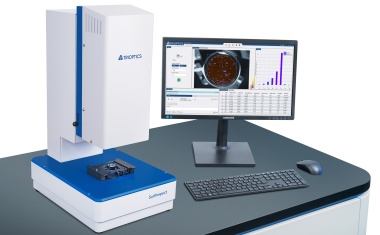

Surfinspect is an automated inspection system for evaluating the surface quality of flat optics and lenses regarding scratch and dig.

Balluff has developed a 25GigE camera family in the most compact housing.

Balluff has developed the most compact cooled SWIR camera in the world. The sensor is cooled by a Peltier element, and the generated heat is transferred directly to the housing.

The Vision Integration Platform Phy VIP from Phytec radically accelerates the development of customized embedded vision systems.

The Blackindustry SWIR 1.7 Pro Max delivers the world’s highest spatial resolution in the SWIR hyperspectral range with 2560 pixels, covering wavelengths from 900 to 1730 nm.

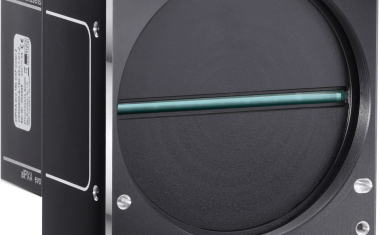

The Allpixa evo 32k CXP mono line scan camera offers high resolution and speed through the combination of high-end CMOS sensors, integrated image processing algorithms, and modern machine vision interface technologies.

The Alecs Smart Camera portfolio is now extended with the Sony IMX993 SWIR sensor, a 3.2 MP InGaAs sensor with 2080 × 1544 resolution, global shutter, and a spectral range of 400–1700 nm.

With the first 3D triangulation camera from the new C7 series, AT Sensors has overcome the previous 1 GigE limit.

With the Native-server-R1, N.A.T. presents a solution that has been specifically developed to meet the challenges of high-end image processing.

Visius is an intuitive and accurate optical coordinate measuring solution at an affordable cost.

The Kowa Rotary Wiper is an machine vision system specifically designed for use in machine tools.

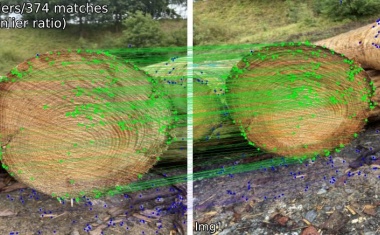

AI-based matching process for object-based recognition without prior training.

The Vision Sensor PV4 is a compact, modular, and freely programmable AI vision sensor for industrial image processing.

The Nion 3D time-of-flight camera combines high spatial resolution with precise depth perception for detailed 3D data, even with fast movements or in difficult environments.

Its Teach‑In Wizard automates the entire setup process, transforming complex parameter adjustments into a fast, intelligent self‑learning workflow that significantly speeds up format changes.

The commissioning of lighting via mobile app enables new features and tools.

Until last year, outgoing goods inspection of wheels could only be done manually. With QBIC Wheels, each wheel is gripped, rotated, and swiveled fully automatically.

The P1PY21x series comprises time-of-flight sensors that operate with blue lasers and are designed for use in demanding environmental conditions.

AI-Loop supports the modeling of AI applications. Data can be managed and AI models trained in the cloud in the AI lab.

QM‑Fit is a compact, intuitively operated vision measuring system that uses automatic part and geometry recognition to begin measurements immediately after the workpiece is placed.

The confocal chromatic high-temperature sensors are designed for measurements in demanding environments.

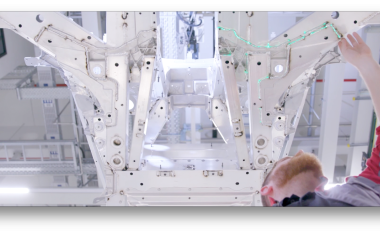

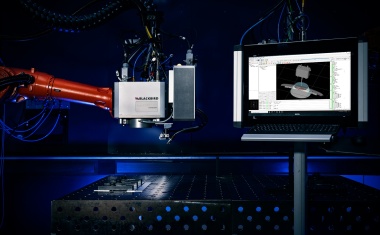

The AI-based solution gives the robot arm human-level capabilities for various manufacturing tasks such as pick-and-place, bin picking, cable insertion, plug insertion, and much more.

Maddox AI is an AI-powered quality platform for industrial manufacturing that automates and digitizes visual inspections.

Multi Line Assist from Göpel Electronic can be used at manual THT assembly stations or in automated production lines.

OCT Seam Inspection is an inline inspection system for optical analysis of weld seams using Optical Coherence Tomography (OCT) in scanner-based laser welding applications.