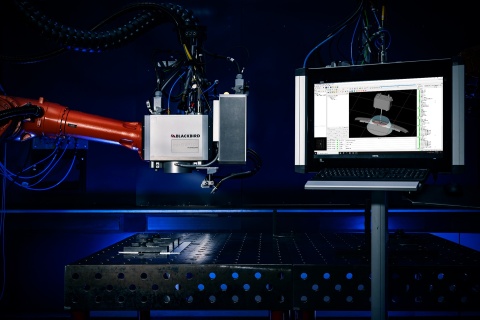

Blackbird Robotersysteme: Quality Assurance System OCT Seam Inspection

OCT Seam Inspection is an inline inspection system for optical analysis of weld seams using Optical Coherence Tomography (OCT) in scanner-based laser welding applications.

OCT Seam Inspection is an inline inspection system for optical analysis of weld seams using Optical Coherence Tomography (OCT) in scanner-based laser welding applications. The system captures seam geometry in real time during the welding process, automatically detects surface and structural defects, and evaluates weld quality based on configurable criteria.

A key innovation is the full use of the available laser scan field without limitations, as well as compatibility with laser beam oscillation — enabled by synchronized control of both the process scanner and the OCT scanner. This high-dynamic, process-neutral inspection allows for early detection of quality deviations, which is particularly critical in high-value applications such as e-mobility.

The acquired raw data is available for AI-driven applications and can be used for machine learning purposes. Additionally, pre-weld process data can be recorded and correlated with seam analysis — for example, to assess molten seam volume or detect dynamic gap variations.