QBIC Wheels - Gigapixel AI surface inspection for aluminum rims

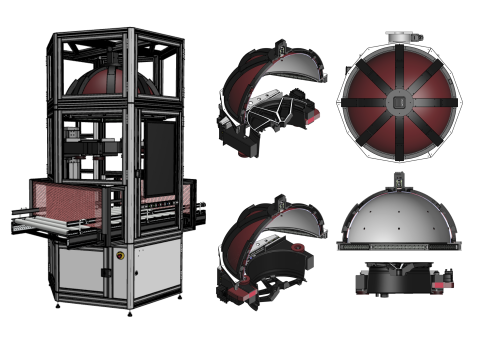

The outgoing goods inspection process at wheel manufacturers is being automated. Until last year, this could only be done manually by employees. With QBIC Wheels, each wheel is gripped, rotated, and swiveled fully automatically.

The outgoing goods inspection process at wheel manufacturers is being automated. Until last year, this could only be done manually by employees. With QBIC Wheels, each wheel is gripped, rotated, and swiveled fully automatically. During the process, well over a gigapixel of image data is generated, which is processed using rule-based image processing and neural networks.

Each wheel is inspected 360° from above, below, and the sides.

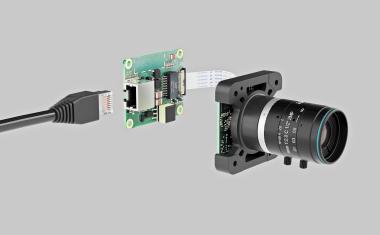

- Total resolution > 1 gigapixel (1,000 megapixels) from 19 cameras, enabling reliable detail recognition

- Compact dimensions, mobile, inline and offline capable

- Offline re-sorting tasks for collected rejects outside the conveyor cycle

- Mechanics and image processing from a single source

- Cycle time < 6 seconds