Focused on laser developments and their suitability for industrial applications

Review: Laser Symposium & ISAM, 29 November – 1 December 2023, Dresden, Germany / online

Review: Laser Symposium & ISAM, 29 November – 1 December 2023, Dresden, Germany / online

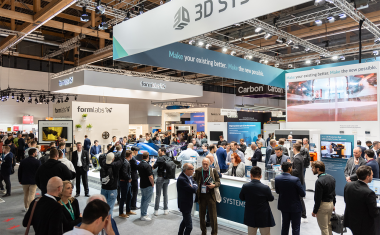

Review: Formnext, 11 – 15 November 2023, Frankfurt, Germany

United by the goal of optimizing the process chain in the field of 3D printing and paving the way to series production.

New type of composite material shows unique optical properties.

The laser manufacturer from Jerusalem has completed the development of a 500-W single-mode cw laser at 532 nm, marking a world record for such a laser type.

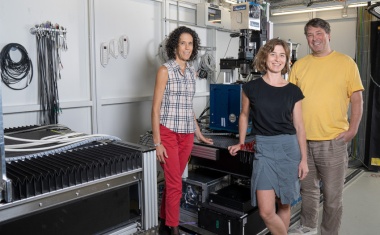

3D tomograms with a speed allowing to follow the laser spot during laser-based powder bed fusion.

ORNL’s machine-learning algorithm Simurgh is now licensed to be used for rapid evaluations of additively manufactured components with industrial X-ray computed tomography.

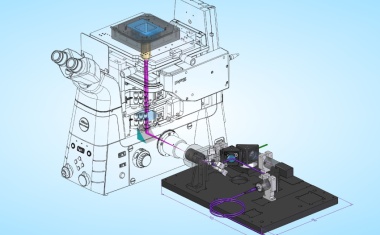

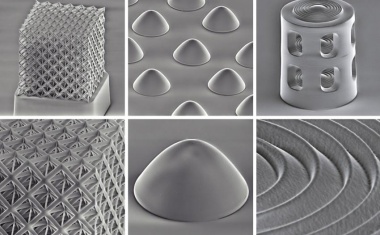

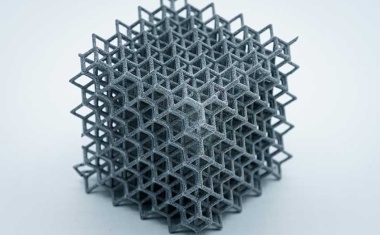

Inexpensive printing system precise enough to create microlenses and metamaterials.

A new simplified technique for creating silica glass structures.

Printed bimetallic material proved to be significant stronger than either metal alone.

New process works at relatively low temperatures and reaches highest resolution for use in optics.

New method uses the NIR invisibility windows of materials to print at a depth of over 5 centimeters.

A promising way to a new class of more sustainable high-performance titanium alloys.

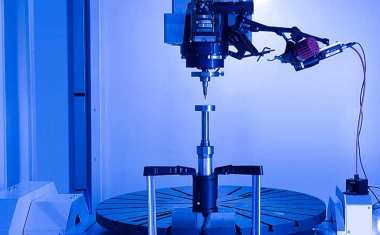

6.7 million euros of funding – Paderborn University is leading a Europe-wide research project.

LightFab, Bartels Mikrotechnik, and Miltenyi Biotec cooperated with the Fraunhofer ILT on producing high-resolution microcomponents by photo-crosslinking.

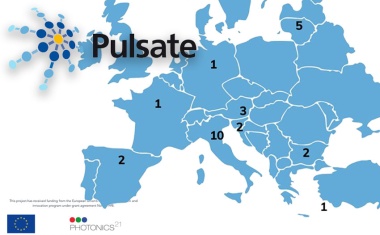

12 experimental projects were successful in the open call for second technology transfer experiments addressing laser-based advanced and additive manufacturing.

Fraunhofer IWS and IAPT together with Australian RMIT centre for additive manufacturing start project “UltraGrain”.

The provider of the GPU-accelerated computation engine used to create next-generation digital manufacturing hardware and software, announced support for the new open vector format (.ovf) by RWTH Aachen University.

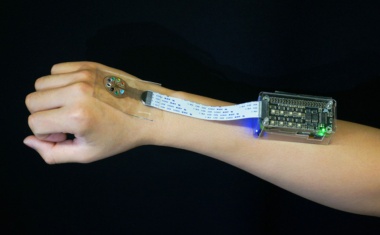

Newly developed smart polymers have life-like properties.

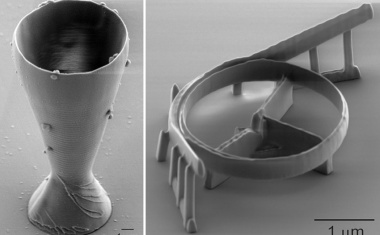

New method can be used for prototyping MEMS devices and manufacturing small- and medium-sized batches.

Shell construction of the second expansion complex completed

Inkjet printer creates Bragg mirrors of variable size with a reflectivity of more than 99 percent.

German government space coordinator pleads for Europe’s independence and know-how in orbit and beyond during Trumpf visit.

For four days, Formnext 2022 turned host city Frankfurt into the global capital of industrial 3D printing.

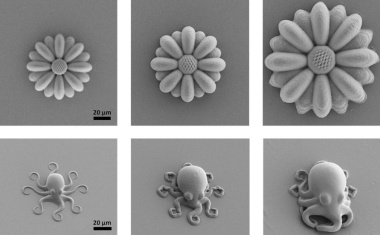

Nanoscribe’s 3D microfabrication range expands to the macroscale while maintaining particularly complex structures and filigree details

Additive manufacturing economically on par with conventional manufacturing – Trumpf gives a preview of new systems and materials to be presented at Formnext.

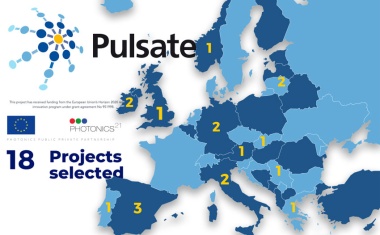

The projects selected by the Pulsate Consortium can start the support program and receive the grant to assess the feasibility of laser-based technology implementation in their environment.

For the eighth time, the international Formnext Start-up Challenge has recognized young companies from the world of additive manufacturing for their innovative business ideas and technical developments.

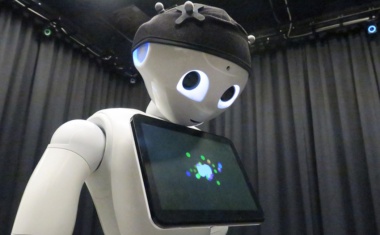

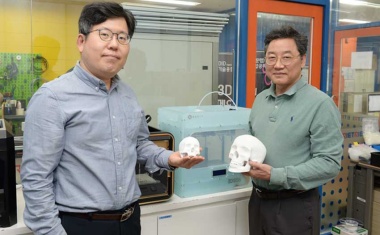

Korean researchers are taking the lead in developing standards for creating patient-customized medical devices. Such standards are expected to be of great help in promoting public health, revitalizing the related medical equipment industry, but also spreading digital twins and metaverse.

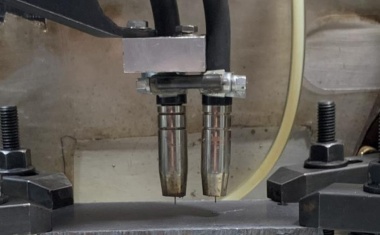

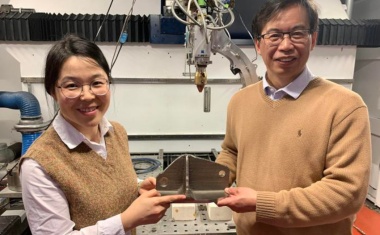

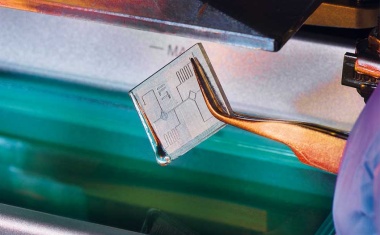

Fraunhofer ILT engineers have developed a new optical system with glass substrates and an arc torch which unites gas metal arc (GMA) welding and laser material deposition with an annular beam, thus creating a completely new process.

Together with its project partner Laserline, the Fraunhofer Institute for Material and Beam Technology IWS has developed applications and specific processes for this laser class to industry readiness under the label “HICLAD”.

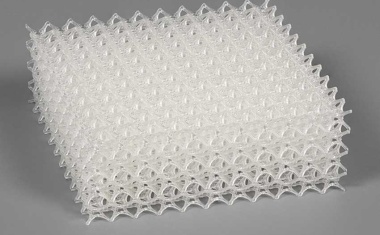

The elastic properties depend on structure size, process and fabrication parameters.

A team from the center for additive manufacturing at Fraunhofer IPA evaluated the technical and economic potential of selective absorption fusion versus selective laser sintering.