Pulsate 2nd round projects selected

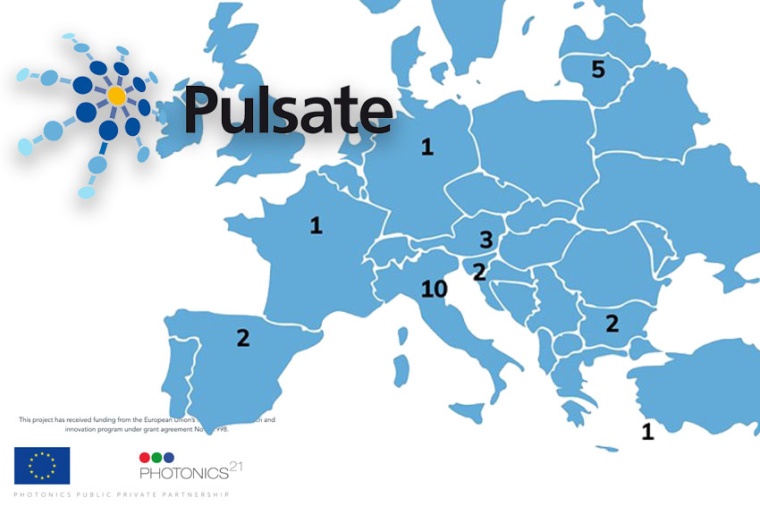

12 experimental projects were successful in the open call for second technology transfer experiments addressing laser-based advanced and additive manufacturing.

The applicants could submit their proposals until the end of July. 34 proposals were submitted and, following the selection process, the chosen proposals will now participate in a 13-month support program. The Pulsate network is designed and dedicated to boosting the adoption of laser-based advanced and additive manufacturing (LBAAM) technology that will empower the European Manufacturing industry digitalization.

Laser-based advanced and additive manufacturing technologies play an important role in furthering digital production and offer important advantages to the companies that adopt them. However, barriers such as high investment costs, complex technology, and system integration, and lack of awareness hinder their adoption by SMEs.

As part of the drive to promote jobs and growth in the European photonics industry, Pulsate was set up in 2020 with a grant of 7.9 million euros under the EU’s Horizon 2020 program as a four-year project to promote and facilitate the adoption of LBAAM technologies.

The selected projects

Experiment: Laser-based 3D manufacturing of electronic systems

Companies involved: Cyber POD, FAE Technology Spa, Armengaud Innovate GmbH

Technology: Laser-based 3D manufacturing for fast prototyping of customized electronics systems targeting a sustainable and resilient European industry.

Experiment: Laser Riblets II

Companies involved: Bionic Surface Technologies GmbH, Biboaqua SL

Technology: Implementation and validation of optimized femtosecond laser riblets to improve fluid-dynamic efficiency of semiaxial submersible pumps.

Experiment: Optical element manipulating geometric phase of laser beam assembled with focusing optics

Companies involved: Altechna R&D, Beamera

Technology: Optical element manipulating geometric phase of laser beam assembled with focusing optics.

Experiment: Improvement and optimisation of the hybrid AM process by advanced digital tool

Companies involved: Balmar doo, Stroka Produkt doo, Distech Disruptive Technologies GmbH

Technology: Development and implementation of advanced digital tool for effective monitoring and optimization of different AM processes.

Experiment: Implementation of new glass cutting technology utilizing femtosecond laser GHz bursts

Companies involved: UAB Precizika Metrology, MB Laser Fabrication Technologies

Technology: Glass cutting technology development utilizing GHz burst of femtosecond lasers.

Experiment: HIGH-Quality large area metal additive manuFACTuring

Companies involved: Dynamic Optics srl, Aconity Gmbh

Technology: Large area laser beam shaping for high resolution and high productivity metal 3D printing.

Experiment: COmpact Blue-light based Additive manufacturing Laser machine for high-Tech customized products

Companies involved: Alite srl, Morphica srl

Technology: Bringing the blue laser revolution in novel concept compact Additive Manufacturing machines for personalized high-tech parts.

Experiment: Sub-Micron hOles driLling by fLExible buRst mode fs laser for nanoparticle analysis

Companies involved: Lithium Lasers Srl, Kirana SRL, Elements Srl

Technology: Manufacturing of reproducible sub-micron on thin polyimide films for nanoparticle detection by a new fs laser source delivering flexible GH.

Experiment: Laser-based repairing application for stamping/forging moulds in automotive industry

Companies involved: Iris srl, Eurodies Italia srl

Technology: Novel approach to laser-based advanced metal additive manufacturing repairing method for long lasting mold.

Experiment: Customized Ultra-Friction Surface Solution

Companies involved: MLEngraving, SKM Aeronautics

Technology: Customized Ultra-Friction Surface Solution: Surface friction management of final parts obtained by mold texturing, instead of sandblasting.

Experiment: SimUlation of DED additive manufacturing ProcEss foR the Manufacturing of a lArge and coMplex shaped

Companies involved: Opt'Alm, CiTD Engineering & Technologies sl

Technology: It consists of using numerical simulation to optimise additive manufacturing process for the manufacturing of large and complex shaped part.

Experiment: Contacting Electronics on textile

Companies involved: Intelectronics OOD, Bulgarlaser 2020 OOD

Technology: Robotic machine for the population of conductive textile ribbon with electronic circuits.

The Pulsate Support Program for Technology Transfer Experiments will start in January 2023 and last for 13 months.Through the program, the Experiments will receive up to 150,000 euros funding per experiment project, a full set of technical and business mentoring services to scale up the experiments, media exposure, and access to private and public funding.

Further reading: 18 projects selected in Pulsate’s 1st open call, wileyindustrynews.com, 13 October 2022