When a laser collar tames the arc

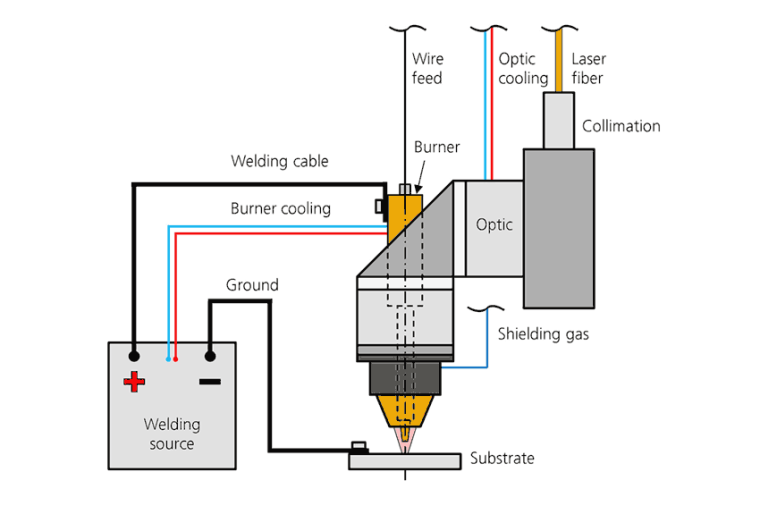

Fraunhofer ILT engineers have developed a new optical system with glass substrates and an arc torch which unites gas metal arc (GMA) welding and laser material deposition with an annular beam, thus creating a completely new process.

The new process combines the best of both worlds: two different additive processes with wire-shaped filler material. We are talking about wire arc additive manufacturing (WAAM) and wire laser material deposition (WLMD). Both processes have system-related advantages and disadvantages: Compared to WAAM, WLMD is costly, has low deposition rates, but is characterized by low heat input and precise layer buildup exactly at the desired location. For this reason, it is particularly in demand in the aerospace industry. If a higher application rate is required, WAAM is the better choice, whereby the achievable surfaces are wavier and the layer buildup is significantly coarser.

In joining, the combination of laser beam welding and gas metal arc welding is established under the name LB-GMA hybrid welding. However, this lateral process is direction dependent and only suitable to a limited extent for joining three-dimensional seams.

When the processes are combined coaxially, the deposition rate can be increased by up to 150 percent, so that the new direction-independent 3D printing process can also be used for large components. “Because the surface waviness decreases, the amount of post-processing required is significantly reduced compared to the WAAM process,” explains Max Fabian Steiner, a research associate at Fraunhofer ILT.

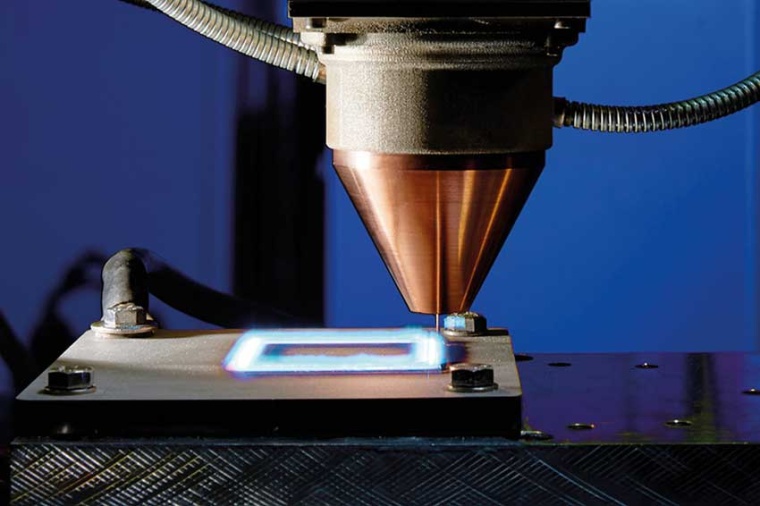

In the hybrid process, the arc between the end of the wire and the substrate is enclosed by the annular laser radiation, as if by a collar. The idea behind this combination is that the arc cannot break out of this collar and is forcibly guided. The new process owes its name, COLLAR Hybrid, to this “forced guidance,” whereby the acronym COLLAR refers to the common coaxial laser arc of the two processes.

While Fraunhofer ILT is using the new system technology to further develop metallic 3D printing with annular-shaped laser beam and arc technology, the RWTH Aachen University Institute for Welding and Joining (ISF) is using it to develop direction-independent hybrid welding with ring focus and coaxial wire feeding. Both use cases are part of the DVS research project KoaxHybrid.

Interested parties can find out how the COLLAR Hybrid process can be used to increase the welding speed and the deposition rate in metallic 3D printing at a specialist congress organized by DVS – Deutscher Verband für Schweißen und verwandte Verfahren (German Welding Society), currently underway in Koblenz, and on October 26 and 27, 2022, at the DVS conference #additivefertigung: Metal in bestForm in Essen.

Company

Fraunhofer Institute for Laser Technology ILTSteinbachstr. 15

52074 Aachen

Germany

most read

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

MVTec Innovation Day 2026: Exchange and insights into machine vision

This event, now in its eighth year, offers the machine vision community a platform for networking and professional exchange.

Basler AG: Change in the Management Board and new CTO position

Long-time CEO Dr. Dietmar Ley will leave the Executive Board at the end of 2025

Purdue University, Rittal and Eplan work together

As part of this partnership, Purdue will open two exclusive laboratories.