3D printing of organic electronics

Researchers achieve microscale organic electronics via multiphoton 3D printers.

Researchers achieve microscale organic electronics via multiphoton 3D printers.

In order to further optimize electric vehicles, researchers worldwide are looking for new concepts as well as manufacturing processes. One possible drive concept for sustainable, low-emission electric mobility is the so-called wheel hub drive.

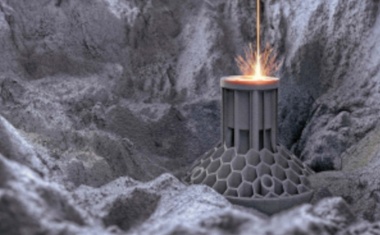

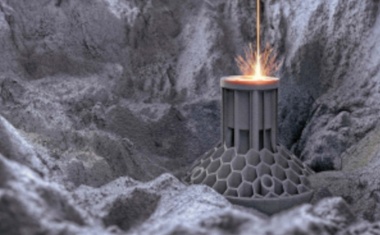

Where two light beams meet, two activated molecules react to form a solid material.

Over 2,500 people attended the 18th Rapid.Tech 3D. They heard about new products and services in additive manufacturing (AM) from 97 exhibitors representing 11 countries. 13 of the exhibitors in Thuringia came from outside Germany, including companies from the US, Great Britain, Austria and Switzerland. Visitors were delighted with the conference programme, and delegate numbers were higher than at the last live conference in 2019.

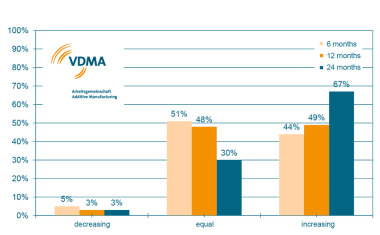

AM processes are playing an increasingly important role in industrial production. Networking within the VDMA helps to further develop this technology of the future.

At sites of BMW in Munich and GKN Powder Metallurgy in Bonn, the results of the IDAM project allows to manufacture more than 10,000 individual and spare parts.

On 2 May 2022, the EU-funded Pulsate project launched the Technology Transfer Experiments (TTE) open call for LBAAM technology in production environments.

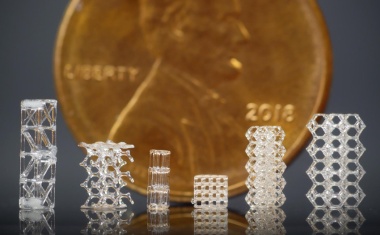

German and American researchers use computed axial lithography to print extremely fine features in glass.

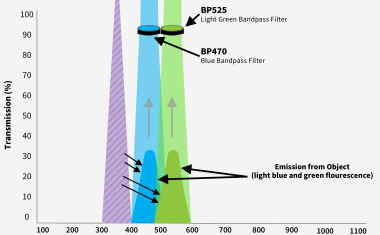

Railroad ties are mainly made of wood. In the production process fluorescent paint helps to determine the wood’s sap side orientation. A combination of red and green bandpass filters from MidOpt ensures that there is sufficient contrast between the fluorescent paint marker and the steel plates that are used to strengthen the wood.

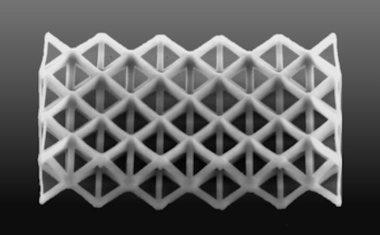

Engineers at Stanford and Harvard have laid the groundwork for a new system for 3D printing that doesn’t require that an object be printed from the bottom up.

Investment plans in AM remain high – technology development of greatest importance in the industry.

Prima Industrie completed the spin-off operation of the business unit dedicated to additive manufacturing.

The agreement marks a collaborative effort to extend the production capabilities of eBeam metal additive manufacturing with the purchase of a Wayland Additive Calibur3 system by EWI.

As demonstrated by research at the Technical University of Munich, the combination of a programmable nLight fiber laser that can toggle between single-mode and ring mode in a matter of milliseconds plus a Raylase optical deflection unit with a zoom axis solves many of the known problems with laser powder bed fusion (LPBF) in 3D printing – such as a lack of homogeneity in the melt pool and reduced production speed.

Based on strong interest from the US market and a solid finance position, UpNano, a commercial-stage technology company and expert in 2-photon polymerization (2PP) 3D-printing, announced it will extend operations to the United States, adding Erika Bechtold as vice president of US operations.

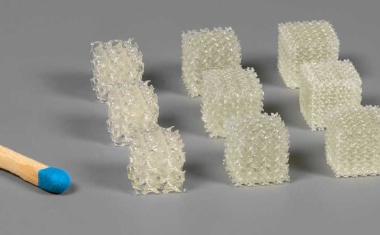

Nanoscribe extends 3D microfabrication to print macroscopic structures with the new Extra Large Features (XLF) Print Set which expands the functionality of an existing machine and turns it into a blazing-fast precision printer for millimeter- and centimeter-sized parts.

German-Belgian four-year research project improves coaxial process for wire-based LMD.

The Fraunhofer Institute for Laser Technology ILT in Aachen and Trumpf Laser- und Systemtechnik from Ditzingen have signed a cooperation agreement. They want to collaborate more closely in the field of laser material deposition and accelerate the transfer of the technology to industry.

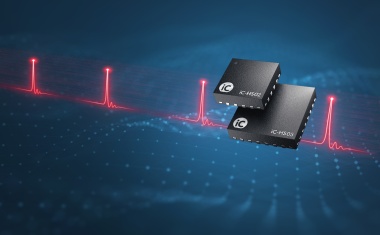

With Covid-19, tuberculosis is one of the deadliest infectious diseases worldwide. A national network of eight companies and non-university research institutions wants to counter this with the help of photonics.

Hexagon’s manufacturing intelligence division collaborates with printer manufacturers Pro-beam, Sciaky, DM3D, Gefertec and Meltio.

New approach opens the door to drastic miniaturization and cost reduction of 3D laser nanoprinters.

The transaction is expected to close by the end of the year, Materialise acquires 100 % of the Link3D equity interests for 33.5 million US dollars.

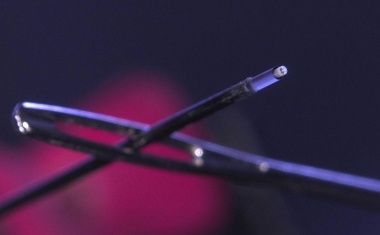

Scientists working on the BW Foundation project Hyazinth have developed a special 3D method that allows complex micro-optics, including apertures or other components, to be printed in a single step. This 3D microfabrication technology can be used to manufacture microendoscopes, for example.

Additive manufacturing processes can eliminate inhomogeneity of titanium alloys during fast cooling – 40 % lighter and super-strong.

The top management of Sisma thanks Trumpf for the collaboration within the joint venture Trumpf-Sisma S.r.l. and look forward to a productive commercial partnership.

Prima Additive, a business unit of the Prima Industrie group, Borsa Italiana, and Materialise, a global provider of 3D printing solutions, are intensifying their collaboration in the optimization of metal additive manufacturing systems.

Now in its seventh year, Formnext 2021 once again gave a warm welcome to the international AM community and, following last year’s online-only event, built on the remarkable successes of previous years.

“This is an auspicious occasion for a retrospective and outlook on our technology,” says Jasmin Saewe, head of the LPBF competence area at Fraunhofer ILT.

The annual international design competition for 3D and 4D printing was concluded in Frankfurt on 18 November 2021 as part of the Formnext exhibition. A total of eight submissions received the coveted gold trophies.

Lasers write the lines by prompting the ink to absorb two photons, initiating free-radical polymerization of the material.

A new generation of particle accelerators aims at taking cancer therapy, drug detection and material analysis to a higher level. Green laser copper AM allows the previously impossible in component optimization.

Highly precise 3D structures in black can now be printed using a 2-photon polymerization (2PP) 3D printing process. This seemed for a long time impossible as non-transmissive (black) materials greatly reduce the polymerization efficiency of the printing process.

Aachen scientists have developed and set up a new precision gripper arm made of metal powder for the first time: a novelty for the assembly of space components in clean rooms. The gripper arm is lighter than its predecessor and yet stable enough to mount and adjust heavier laser optics with ultraprecision.

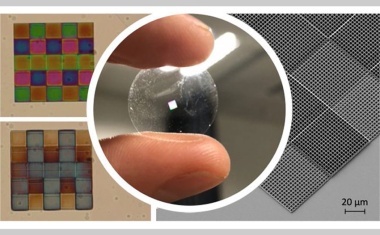

Using direct laser writing, arrays of optically responsive ionogel structures were fabricated. They show visible color changes in the presence of different solvent vapors.

Kif Parechoc, an expert in watch movement components, has signed a highly innovative partnership agreement with AddUp, a French specialist in industrial metal 3D printing, to use metal additive manufacturing (AM) for very high precision watchmaking purposes.