Two steps to the goal

LightFab, Bartels Mikrotechnik, and Miltenyi Biotec cooperated with the Fraunhofer ILT on producing high-resolution microcomponents by photo-crosslinking.

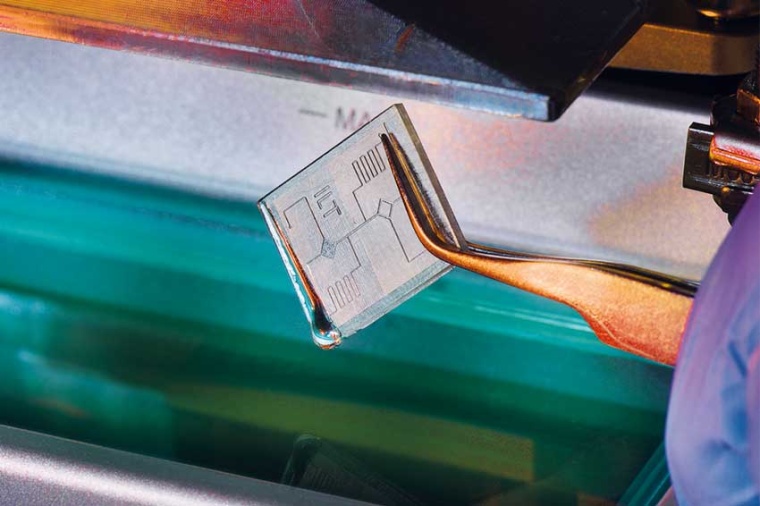

The project “High productivity and detail accuracy in additive manufacturing by combining UV polymerization and multiphoton polymerization – HoPro-3D” aims at producing polymer microstructures economically and customized in one machine. To do so, the project partners developed a new type of 3D printer that combines fast two-dimensional exposure – scrolling digital light processing (DLP) – with a high-resolution laser process – multiphoton polymerization (MPP) – to produce microcomponents from photopolymers.

The HoPro-3D 3D printer has two selectable exposure systems, for either high build rates (scrolling DLP) or high precision (MPP). The DLP module, which emits at a wavelength of 365 nm, exposes the basic structures of a microcomponent with a pixel resolution of 10 µm. As a complement, a femtosecond laser and the MPP module can be used to write contour lines with a resolution of about 2 µm.

The layer-by-layer approach makes it possible to build the finest MPP structures on top of already printed DLP structures, thus quickly creating extended components with a complex structure and high-resolution details. The built-up laboratory pattern allows the production of components with a footprint of up to 60 × 100 mm².

Combining processes quickly and precisely

The control software of the HoPro-3D system enables users to smoothly switch between the two exposure modules. Moreover, they can use CAD data to decide when it makes sense to switch between the printing processes. During the layer-by-layer buildup of a component, it is possible to switch between the two processes several times.

“The concept is in place and the corresponding machine has been built and already extensively tested,” reports Dr Martin Wehner, head of the biofabrication group at the Fraunhofer Institute for Laser Technology ILT. After completion in 2022, the laboratory prototype could already be tested and optimized in an application-oriented manner as part of the Fraunhofer SiCellNet network. The SiCellNet cluster forms a central point of contact for research into new tools and manufacturing techniques for the analysis, sorting and provision of living cells. The performance of the combination plant and the control of the process could thus be optimally expanded.

In the follow-up project “Precise assembly by high resolution seamless 3D printing – PANDA,” funded by the SME Innovation Program, the ILT team has been expanding the performance of DLP-based processes since January 2022. The knowledge gained there will later be applied in the HoPro-3D system to continuously improve the economic efficiency of the 3D printing process.

Company

Fraunhofer Institute for Laser Technology ILTSteinbachstr. 15

52074 Aachen

Germany

most read

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

MVTec Innovation Day 2026: Exchange and insights into machine vision

This event, now in its eighth year, offers the machine vision community a platform for networking and professional exchange.