How to go from nano to macro in 3D printing

Nanoscribe extends 3D microfabrication to print macroscopic structures with the new Extra Large Features (XLF) Print Set which expands the functionality of an existing machine and turns it into a blazing-fast precision printer for millimeter- and centimeter-sized parts.

The Karlsruhe-based member of the Bico group introduced an expansion of the manufacturing range for its high-precision 3D printer Quantum X shape from nano- and microscale structures to macroscopic objects, while maintaining particularly complex structures and filigree details. The new XLF Print Set speeds up high-precision 3D printing many times over, making the Nanoscribe machine the preferred choice for batch production of voluminous objects.

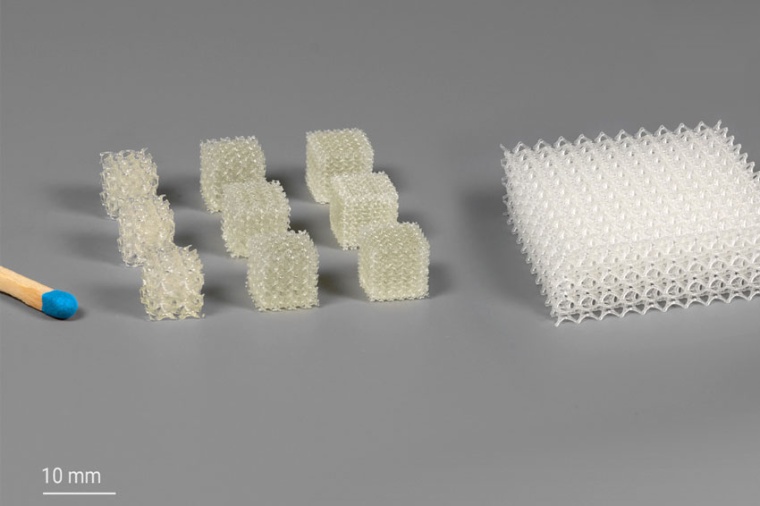

Thanks to the inherent advantages of Two-Photon Polymerization (2PP), this high-precision 3D printing technology is proven to be at least one hundred times more precise than comparable technologies such as high-resolution SLA and DLP or projection microstereolithography (PµSL). Until now, 2PP was limited to object sizes of just a few millimeters. With the new set, the high-precision 3D printing technology can now be seamlessly extended to centimeter-sized objects, with precision typically two to five times higher than comparable microfabrication technologies. In a single pass, objects up to thirty cubic centimeters can be produced.

“The XLF Print Set brings a whole new world of opportunities to the Quantum X shape,” says Dr Michael Thiel, chief science officer and co-founder of Nanoscribe. “First and foremost, you gain a tremendous speed up in manufacturing large print quantities of voluminous objects in one batch,” Thiel summarizes one key benefit of the new XLF Print Set.

The XLF Print Set now makes it possible to print large parts with filigree features or even many millimeter-sized parts with complex structures or finest details. The Nanoscribe Quantum X shape is a laser-based 3D printing platform with straightforward processes and reliable workflows, so highly precise and accurate printing results are also achieved with the new XLF Print Set. It contains a new air objective with a magnification factor of 5x, resulting in an increased print field diameter of up to 3,200 µm and a comparatively large working distance of 18.5 mm. Combined with a high scanning speed, adjustable voxel sizes, and a highly sensitive photopolymer resin, the XLF Print Set provides a comprehensive solution for high-precision 3D printing in the milli and centimeter range. It is therefore an attractive solution for prototyping and manufacturing, for example, mechanical parts such as millimeter-sized connectors and housings, microfluidic structures, and scaffolds for biomedical research.

Company

Nanoscribe GmbH & Co. KGHermann-von-Helmholtz-Platz 6

76344 Eggenstein-Leopoldshafen

Germany

most read

Helukabel joins the IPAI

This platform promotes the development and application of artificial intelligence (AI) through collaboration between companies, research facilities and institutions.

Dr. Marc Lünnemann new CEO at Instrument Systems

Lünnemann took up the position on January 1, 2026 and brings with him over 20 years of international experience in the lighting, automotive and display industries.

Engineering labor market under pressure: shortage of skilled workers despite the crisis

Unemployment in IT and engineering professions rose by 17.6 percent, while the total number of vacancies fell by 23 percent to 99,470.

EMVA at the Logimat 2026

EMVA members will be demonstrating their products at the joint stand in Hall 2.

MVTec and Qualcomm: New partnership for faster deep learning applications

By integrating MVTec Halcon with the Neural Processing Units (NPU) of Qualcomm Dragonwing processors, smart cameras in particular will benefit from increased speed and efficiency.