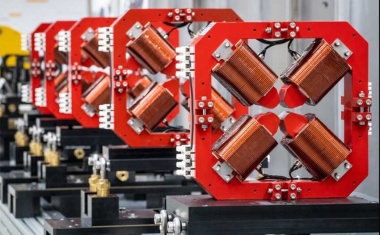

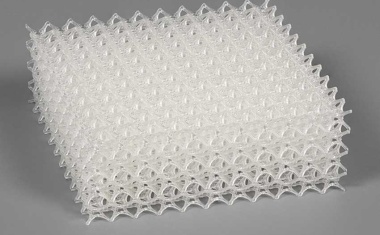

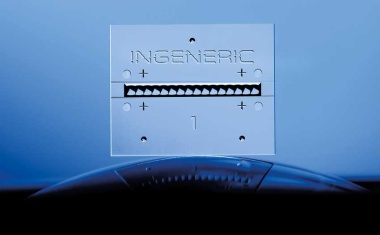

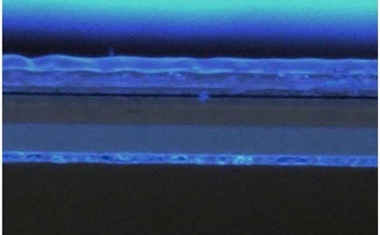

Flexible laser plastic welding as an addition to AM

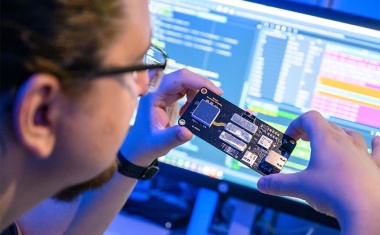

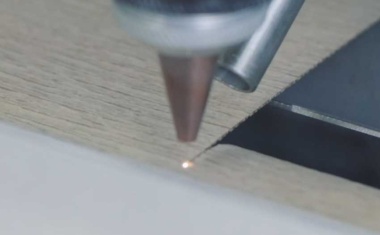

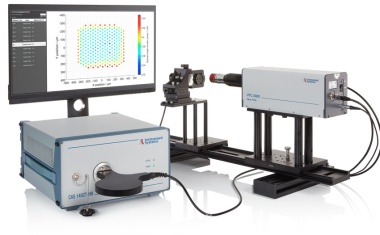

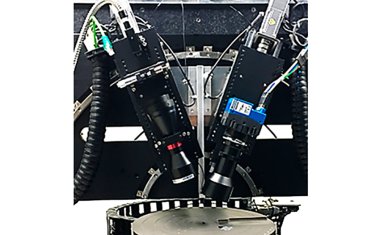

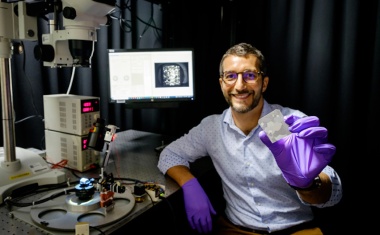

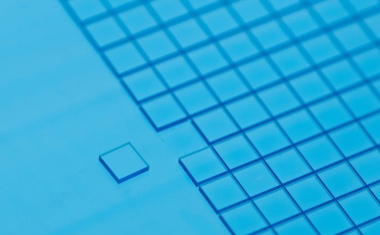

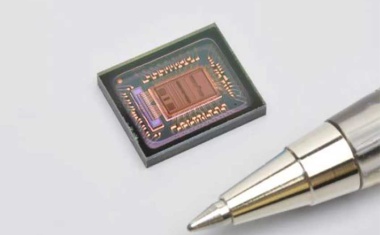

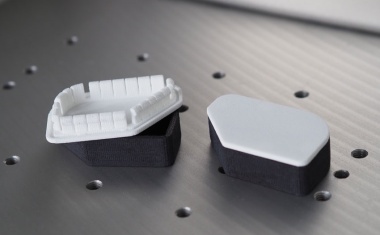

Individualization, shorter product cycles and prototyping are leading to increased use of additive manufacturing in industry. A reliable and versatile process like laser plastic welding is needed to join parts with other additively manufactured or injection molded parts.