Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept. TÜV SÜD identifies five key trends that will shape the market in 2026.

1. Intelligent Sensor Technology and Networked Monitoring

Industrial IoT and smart sensors enable real-time monitoring of machine conditions. This increases efficiency, but also the attack surface for cyberattacks. Manufacturers must protect security software, firmware and control systems against manipulation.

2 AI for Process Optimization and Predictive Maintenance

Artificial intelligence makes machines more flexible and detects failures at an early stage. Prerequisite: data integrity. As there are still no harmonized standards, individual security concepts and risk assessments are mandatory.

3 Automated Safety Control Systems

Autonomous safety control systems react independently to critical situations. Networked systems require robust protective measures in accordance with standards such as IEC 62443. Automation engineers must think functional safety and cybersecurity together.

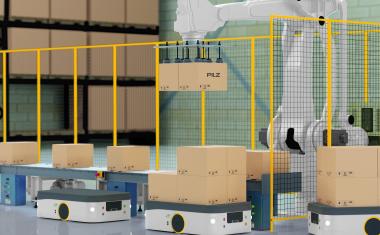

4 Collaborative Robots with Integrated Safety

Cobots with AI replace safety cages and take on changing tasks. Secure communication between humans, robots and IT systems is crucial for trouble-free operation.

5. Cloud-Based Safety Management Systems

Cloud solutions enable the central analysis of safety-relevant data. At the same time, the requirements for data protection and cyber resilience are increasing - regulated in the EU Cyber Resilience Act and AI Act.

Conclusion: Machine safety in 2026 means more than just physical protective measures. It includes safeguarding digital processes and complying with new standards such as the EU Machinery Regulation. Automation companies that respond to these trends at an early stage will secure competitive advantages.