3D Scanner Improves Aerodynamics and Driver Comfort for Endurance Racing Cars

Optical CMM Scanner Used by Racing Team

To test the shape changes on the underside of a race car to obtain downforce and aerodynamics, a race team uses an optical CMM scanner with 15 laser crosses and a rate of 1,800,000 measurements per second. It has also been used to optimize the ergonomics of the cockpit so that the driver can concentrate better and give his best throughout the race.

From the first Paris-Rouen race in 1894 to iconic events such as the 24 Hours of Le Mans and the 24 Hours at Daytona, endurance racing has captivated the world as a premier motorsport showcasing the mastery of drivers, the durability of cars, and the art of engineering. In their quest for victory, racing teams worldwide relentlessly seek solutions to gain a competitive edge, resulting in advances in vehicle engineering, aerodynamics, driver ergonomics, and the use of cutting-edge technologies.

Wayne Taylor Racing with Andretti Autosport (WTR Andretti) of Indianapolis, Indiana, competing in the IMSA Weathertech Sportscar Championship and the North American Lamborghini Super Trofeo Series, is one of those teams. In 2022, the team partnered with Creaform, a manufacturer of portable 3D measurement solutions, to improve their sports cars’ aerodynamics and driver ergonomics.

Optimizing underbody aerodynamics with 3D measurement technology

One of the applications for which WTR Andretti engineers have chosen to use Creaform solutions is to improve underbody aerodynamics. The underbody is essential for generating downforce, managing the car’s airflow on the track, and optimizing the overall grip. Since the underside makes repeated contact with the track and accumulates wear and tear, it’s important to test its shape changes to maintain downforce and aerodynamics.

Before Creaform, the team used tape measures or calipers to analyze and measure all the underside deformations. But these measurements weren’t reliable. To solve this problem, the team turned to professional 3D scanners.

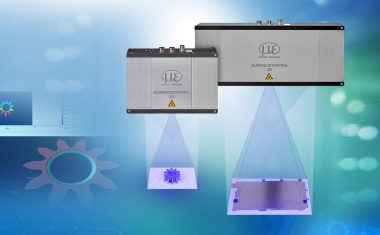

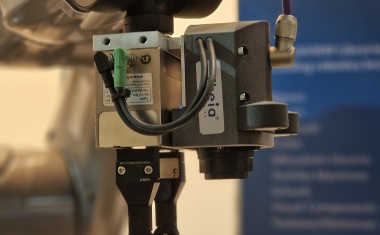

They chose Metracan 3D, an optical CMM scanner with 15 laser crosses and a rate of 1,800,000 measurements per second, allowing WTR Andretti engineers to accurately measure complex surfaces in minutes. With an accurate 3D digital model of the car’s underside, they can now determine how much loss and wear the car’s underside has experienced during the race, how it correlates to aerodynamic losses, and which parts need better protection.

Innovating cockpit design for more driver’s comfort

Another area where the team has used the scanner is cockpit ergonomics. Endurance racing can last several hours or even a full day, putting immense physical and mental strain on the drivers. Optimal cockpit ergonomics, such as well-positioned controls, supportive seating, and proper pedal placement, help minimize driver fatigue and discomfort, allowing them to stay focused and perform at their best throughout the race.

To that end, WTR Andretti engineers scanned the entire interior of one of their most technologically advanced cars, the No. 10 Konica Minolta Acura ARX-06. This allowed the team to determine the driver’s position next to every component in the cockpit and see which parts could be adjusted to suit the individual driver's characteristics and preferences.

Autor

Olivier Plamondon, Product Manager at Creaform

Company

Ametek GmbH - Division Creaform DeutschlandMeisenweg 37

70771 Leinfelden-Echterdingen

Germany

most read

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy

Productivity Boost for the Frontline

Machine Vision and AMRs as Part of AI-Driven Strategies in Manufacturing and Warehouse Operations

Simplified Integration

Intelligent Lens Systems for Remote and Mobile Applications

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People