Automatic Defect Detection in Laser Welding and Brazing with AI

Process Monitoring in Automotive Production

Dr. Christian Petersohn, Senior Software Developer at Scansonic MI, and Dr. Michael Ungers, Product Owner at Scansonic MI

Smart sensor technologies are key for Industry 4.0. But data alone is not enough. It must also be interpreted effectively. Artificial intelligence makes it possible to automatically detect defects in laser-joined seams with high detection rates. This marks another significant milestone in the digital transformation of automotive manufacturing.

It all started with a request from the German plant of a U.S. car manufacturer preparing for a model update. In the previous mid-size car version, roof and side panels were joined using spot welding and concealed behind decorative strips. The new model would forgo these strips. But exposing the seams to the customer’s eye leads to increased requirements on the weld quality. At the same time, the production team aimed to digitize more of its processes.

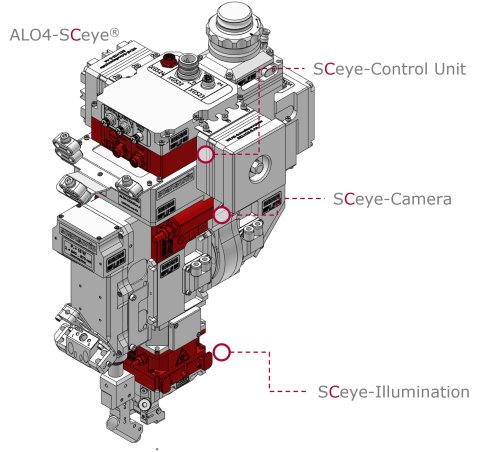

The search began for a different joining method. The project team identified laser brazing as the optimal solution and reached out to Scansonic. The ALO4 laser processing optics – featuring tactile seam tracking and additional filler wire – has proven itself globally in this application. The integration of a camera enables online monitoring. Artificial intelligence (AI) can be used to analyze the images provided by the camera to assess the seam quality – a capability the customer wanted to explore further.

AI-Enhanced Process Monitoring

The ALO4 represents the fourth generation of tactilely guided laser processing optics in automotive manufacturing. Since 2017, the ALO has been equipped with the SC Eye monitoring system, consisting of an integrated illumination-module, a camera, and a control module. Automated image processing was a decisive factor in the customer’s choice. But for three years now, the system does more than visualizing the process: The AI identifies defects such as spatter or pores in real-time. AI essentially takes over visual inspection, as operators are shown images of detected failures and can decide on rework, accordingly.

Customer Learning Curve

The integration of the laser brazing technology into the customer’s production processes took several months in total. The ALO4 with the integrated SC Eye system generated large volumes of image data during the production process. These data have been essential to train an AI model and made efficient data management essential. To enable this, standards for data processing had to be established to ensure efficient handling both on the factory floor and at Scansonic.

In the meantime, the new technology has been fully integrated into the production system. Detected defects are automatically assigned to a specific vehicle and displayed to the operator. Based on the classification by the AI, the defective part is directed to a repair station.

Following the initial successful implementation phase, even the smallest defects were identified. Customer evaluations showed that the system reliably detected failures as small as 0.2 mm. This is particularly important, as pores of this size can no longer be sealed by paint or may reappear during subsequent processing steps.

Processes are Fully Traceable, even across factories

In the production line, a robot places the roof onto the body, and two more robots guide ALO4 optics along the seam to join roof and side panels. All defect-related videos are stored with metadata such as vehicle ID, materials, and tool settings. This makes processes fully traceable and optimizable, even across factories or plants. AI-based quality monitoring is becoming a key component on the road to fully digital workflows.

Further advantages are expected in the future – for example, setup times are anticipated to become shorter. Because of AI, fewer tests are needed when adapting processes.

What the AI Actually Does

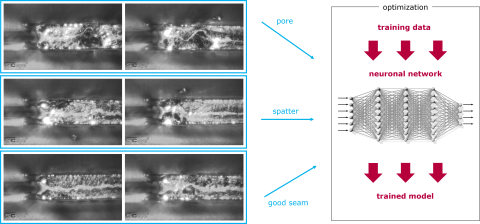

Essentially, the AI mimics human learning. A convolutional neural network (CNN) is trained on images of good and defective seams – in this case, two defect types: “pores” and “spatter”. The CNN detects these in real time and can be trained for other defect types as well. Scansonic is actively collaborating with universities and industrial partners to further enhance the detection rate of the AI model.

Machine Learning and New Processes

For the initial training of the system, the customer provided approximately 5,500 images of good brazed seams and around 2,000 images showing pores. Scansonic was able to demonstrate in its laser laboratory that only a small number of additional images were required to transfer the good detection results to similar processes. With just a few hundred images, detection rates of over 95 percent were achieved for brazing processes that differed only slightly from the automotive manufacturer’s series production; primarily in terms of the materials used and the process parameters applied. Even when transferring the AI-based detection approach to entirely different laser processes, such as aluminum laser welding, retraining with only a few images still delivered excellent results for the new process.

Towards Zero Training?

Today, the system is installed at more than five different customers. Currently, each application is still trained individually. In the future, the AI could become significantly more powerful if training data from various applications were combined. This would allow the AI to be trained on a wide range of use cases, resulting in a highly advanced model that delivers optimal performance across all applications.

With this future approach, any customer willing to contribute their training data would benefit from the best-trained AI available. In the long term, this could lead to the creation of a database that eliminates the need for individual training altogether.

Looking ahead, data from other detectors (e.g., spectral analysis of process emissions) or from process parameters could also be incorporated. This would pave the way towards another strategic goal: complete process optimization through AI. A separate AI could suggest optimized process settings to the operator or even configure the entire process automatically. Although this visionary goal is still on the distant development horizon, Scansonic’s development team is already laying the foundation today.