Pyroelectricity: detecting the infrared

100 years and very much alive and kicking – ferroelectricity has been researched and used until the present day.

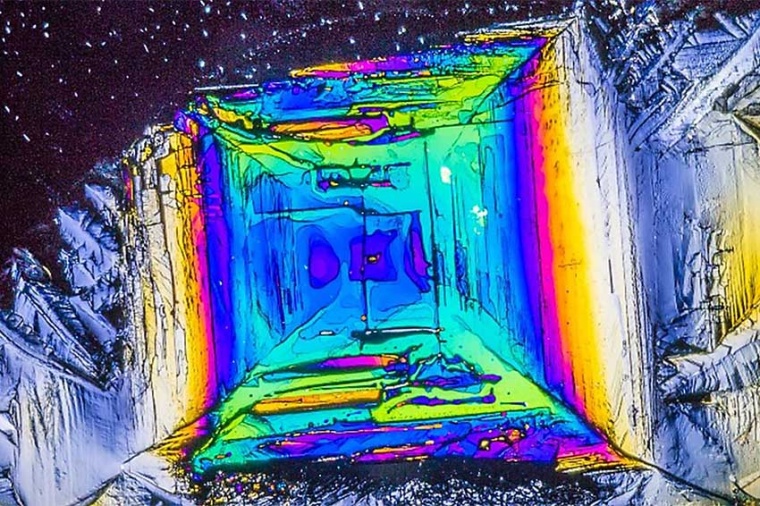

A century ago, Joseph Valasek discovered the phenomenon of ferroelectricity in potassium-sodium tartrate-tetrahydrate, also known as Rochelle or Seignette salt. He initially observed hysteresis curves of the dielectric polarization under the influence of an electric field. Valasek formulated that the ”dielectric displacement D, the electrical field E and the polarization behave analogue to the magnetic values B, H and I“. Piezoelectric and pyroelectric characteristics had been investigated on crystals such as tourmaline and quartz long before Valasek. He followed these investigations and paved the way to the exploration of ferroelectric crystals. These can, like pyroelectric crystals, exhibit a ‘natural’ polarization, however, the polarity can be reversed by an electric field. Further ferroelectrics were found during the following years and rapidly applied in ultrasonic transducers as a result of their outstanding characteristics. Today ferroelectrics can be found in many everyday devices, e.g. as non-volatile memories in electronic systems, as piezoelements in loudspeakers and lighters and also as pyroelectric detectors in gas and flame sensors.

The scientific journal APL Materials dedicated a special edition “100 Years of Ferroelectricity – a Celebration“ to the discovery of ferroelectricity. Dr Neumann and two other experts from the research and development department of InfraTec GmbH Infrarotsensorik und Messtechnik have participated in this special edition with the specialist article “Advantages and limitation of Mn doped PIN–PMN–PT single crystals in pyroelectric detectors“. Although lithium tantalate is the customary material for InfraTec detectors, further pyroelectric materials are being researched with the objective of improving the performance and producing more cost-effectively and also with high process safety. The publication compares lithium tantalate monocrystals and monocrystals on the basis of lead-magnesium niobate as materials in pyroelectric detectors. In addition to relaxor ferroelectrics based on lead-indium niobate – lead-magnesium niobate – lead titanate (PIN-PMN-PT) the team also researched on composites from the ferroelectric polymer PVDF and PZT thin films.

The pyroelectric effect is the basis for the infrared detectors of InfraTec and a broad field for the continuous investigation of pyroelectric materials and processing technologies. One person, who has always been involved in the further development and optimization, is Dr Norbert Neumann. Together with Drs Matthias Heinze and Matthias Krauss he founded InfraTec GmbH Infrarotsensorik and Messtechnik in 1991 and became head of development in the sensor technology division some time later. At the beginning of the 2000s, he and his team developed a new class of pyroelectric detectors with integrated transimpedance amplifier for current operation, e. g. the LME-336 (single channel) and the LMM-244 (4-channel), followed by the generation of tunable detectors (microspectrometers), which are equipped with the Fabry-Pérot filter that has received numerous awards. A patented solution for the installation of the pyroelectric elements, which arms the detector against vibrations or mechanical shocks, also came out of the InfraTec research laboratories in the last few years as the LME or LMM series.

The development of new and stable technologies for the processing of the LiTaO3 wafers, e. g. for the application of the absorption and electrode layers, has been accompanied by the sensor development department since the beginning of production. The automatic measuring systems with which the sensitivity and the murmurs of the detectors are measured are an essential prerequisite and building block of our quality philosophy. No detector leaves the InfraTec production shops without electro-optical product testing.

The intentions of the advanced development to ferroelectric materials included increasingly extensive investigations into the feasibility and risks for serial production alongside the technical enthusiasm. This laid the foundation stone for a well-equipped development laboratory, which is available to the engineers from development, product management and technology, and is even used by our customers for application support.

After twenty years of division leadership by Dr Neumann, Dr Martin Ebermann will take over the advanced development and material research. Neumann will continue his activities as adviser to InfraTec and carry on with his supervision of the Project Polar, with the objective of the development of a completely CMOS-compatible, pyroelectric sensor on the basis of hafnium oxide. Moreover, he will accompany the qualification of an in-house DLaTGS crystal growing scheme in serial status.