Manz opens Laser Application Center

Companies can check the best joining technology for new products in terms of mechanical strength, welding time, cost and quality, in Manz’s new Laser Application Center (LAC).

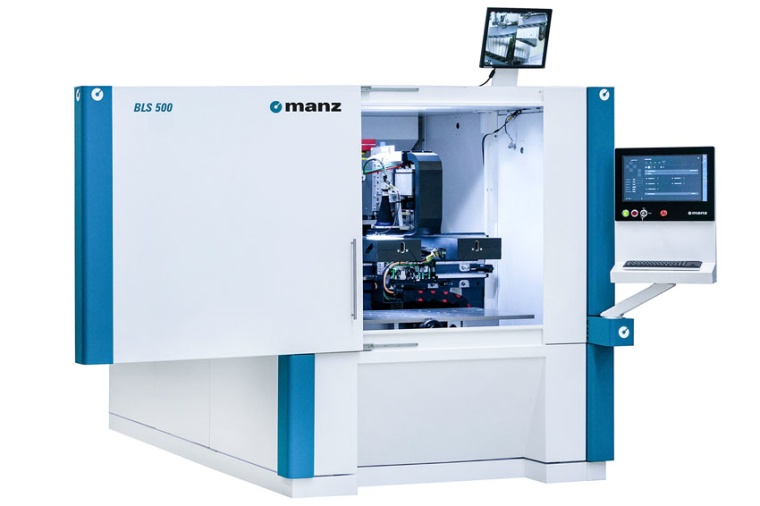

With the Laser Application Center (LAC) in Reutlingen, Manz now offers companies a unique production environment for testing and optimizing various laser welding processes and material combinations under real conditions and for creating samples of the respective products. The production facilities at the LAC cover all common laser welding processes and laser sources. Manz categorizes them into four different processes: short-pulse laser welding, single-mode laser and local laser beam oscillation (‘wobbling’), multimode laser (IR) and special beam shaping, and frequency-doubled multimode lasers (‘green’ lasers).

The LAC’s test environment offers companies an ideal opportunity to test and analyze in advance the appropriate laser welding application for their specific requirements. For example, they can evaluate the best joining technique in terms of mechanical strength, welding time, cost, and quality. Currently, the LAC is already being used by companies in the automotive and energy storage industries, for example, to develop processes for manufacturing battery cells and modules or to optimize existing production processes.

In addition to access the LAC, Manz also offers companies accompanying service packages. For example, Manz’s laser competence team advises on the preselection of materials and processes, provides support for any necessary pre and postprocessing of the materials (such as cleaning before welding), and can conduct tests regarding quality if required. This includes, for example, monitoring of welding depth, process parameters and emissions. In addition, the team of experts assists with the analysis of the respective processes. This includes cycle time analysis of the individual welding processes and micrograph analysis. This enables companies to examine the weld seam at an early stage of development and find the optimum welding parameters, the optimum welding depth, and the highest pull-off strength.

“Laser welding is usually a critical moment in the overall process. Companies can already test this in the LAC during process qualification. With our offer, we help our customers to test and evaluate different materials and laser processes. In this way, we significantly shorten the development process of new products and accelerate the release for series production,” says Sascha Gaiser, technical head of the LAC.

Company

Manz AGSteigäckerstr. 5

72768 Reutlingen

Germany

most read

Engineering labor market under pressure: shortage of skilled workers despite the crisis

Unemployment in IT and engineering professions rose by 17.6 percent, while the total number of vacancies fell by 23 percent to 99,470.

EMVA at the Logimat 2026

EMVA members will be demonstrating their products at the joint stand in Hall 2.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Helukabel joins the IPAI

This platform promotes the development and application of artificial intelligence (AI) through collaboration between companies, research facilities and institutions.