On-the-fly laser welding for more efficient, lower-cost production

Blackbird’s open house event attests to robust industry interest.

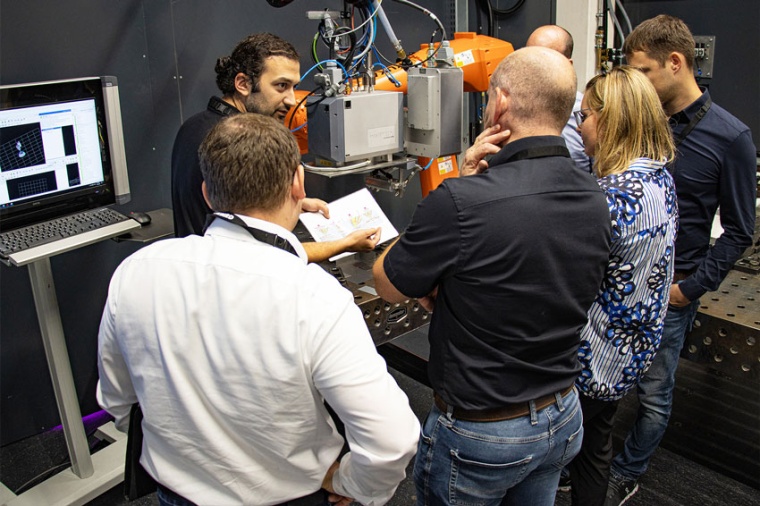

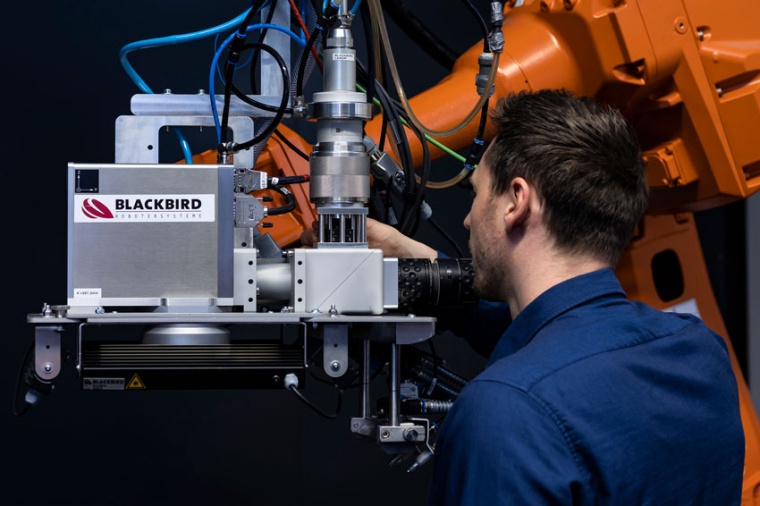

The manufacturer of system solutions for remote laser welding Blackbird Robotersystem kicked off extensive dialogue between laser technology experts and representatives of the electric mobility industry with its open house event on July 16, at the afternoon before the LaserEMobility wokshop at the TU Munich campus. More than sixty guests from seven countries attended the expert welding company’s event in Garching. Attendees came from major automotive manufacturers and suppliers, as well as photonics component suppliers.The centerpiece of the event was a series of live demonstrations of innovations such as on-the-fly laser welding of battery cells.

Garching, near Munich, was recently host to three days focusing on innovative laser technology for the electric mobility environment. Blackbird held an open house at its laser labs on Tuesday, July 16, to kick off the series. Over the next two days, the Technical University of Munich (TUM) partnered with two Italian higher education institutions and welcomed some two hundred guests at the Science Congress Center Garching at its LaserEMobility Workshop.

The more exclusive event at Blackbird gave approximately sixty visitors an opportunity to see new developments in the systems with their own eyes in live demonstrations, to understand the benefits, and to prove how suitable the new solutions are for industrial production. The event was also a chance for visitors to talk with experts about their individual requirements. Demonstrations ranged from an innovative setup for automated mass production of battery packs consisting of many individual round battery cells, to OCT-monitored laser welding of three-dimensional components with varying joint geometries, to safe, reliable, and efficient welding of hairpins.

“I was pleasantly surprised by the success of our event and by the high level of expertise we saw in people’s questions,” says Benjamin Bopp, head of sales at Blackbird, who joined the team just a few months ago. “Once again, this affirms my personal experience and Blackbird’s excellent reputation as a technology leader in remote laser welding, especially for all on-the-fly (OTF) applications. After participating in trade fairs in China, the USA, and Korea this year, it was extremely important for us to bring together our leading users in Germany as well. And the open house was the perfect solution to do so.”

Further reading: Global experts gather to advance laser-based manufacturing for e-mobility – Review: LaserEMobility Workshop 2024, 17 – 18 July 2024, Garching near Munich, Germany, wileyindustrynews.com, 9 August 2024 • Ralf Nürnberg (Blackbird), Holger Schlüter (Scanlab): High precision laser welding for the electric vehicles of tomorrow – How to maximize output in bipolar plates and battery manufacturing, PhotonicsViews 21(2), April/May 2024, pages 28-31; DOI: 10.1002/phvs.202400007

Company

Blackbird Robotersysteme GmbHCarl-Zeiss-Str. 5

85748 Garching

Germany

most read

Digikey renews platinum sponsorship of WE United

Linda Johnson, Executive Partner at Digikey, emphasized the importance of the partnership in supporting the professional entry of women worldwide.

Dr. Marc Lünnemann new CEO at Instrument Systems

Lünnemann took up the position on January 1, 2026 and brings with him over 20 years of international experience in the lighting, automotive and display industries.

EMVA at the Logimat 2026

EMVA members will be demonstrating their products at the joint stand in Hall 2.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.