A fiber-to-SiPh PIC coupling solution

Created using the company’s proprietary high-speed laser writing technique, the solution is designed to overcome fiber-to-SiPh photonic integrated circuit (PIC) coupling challenges to enable high volume automated assembly and help drive down costs.

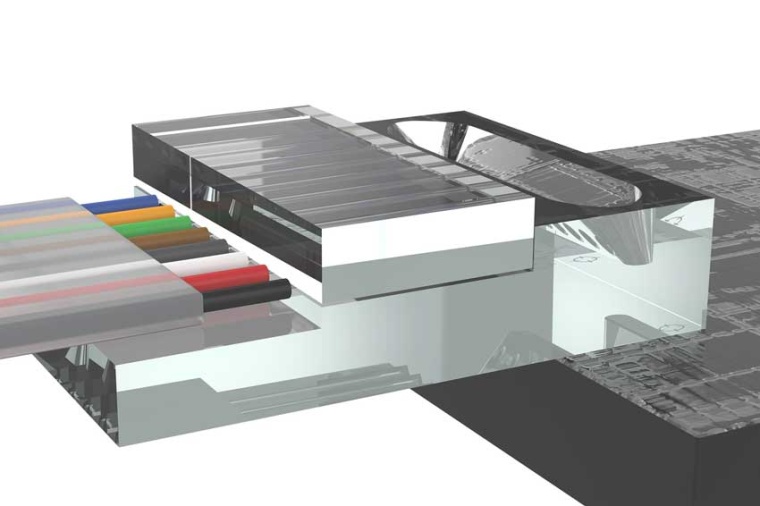

Optoscribe’s OptoCplrLT uses low-loss light turning curved mirrors, which are formed in the glass, to direct the light to or from the SiPh grating couplers. This prevents the need for bend-tolerant fiber solutions, which are often expensive, challenging to manufacture and have some significant limitations in size and profile.

OptoCplrLT has a low-profile interface, ~1 mm device height and ~1.5 mm with cap, which allows compact interface layouts that alleviate packaging constraints and helps address footprint challenges. The solution is also compatible with industry-standard materials and processes; for example, the glass chip has a coefficient of thermal expansion matched to the silicon chip, helping to maximize performance.

Russell Childs, CEO of Optoscribe, said “We are pleased to announce that we are now sampling OptoCplrLT, which offers data center operators, transceiver manufacturers and optical component suppliers an innovative solution to help address fiber-to-SiPh PIC coupling challenges and help overcome SiPh transceiver packaging and integration hurdles, while meeting market demands of performance, cost and volume.”