3D-Micromac systems for Infineon

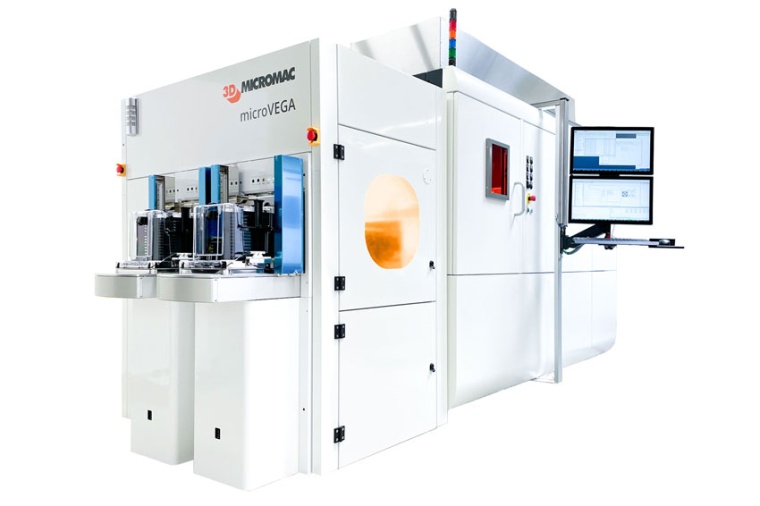

Laser micromachining expert exclusively supplies new Dresden Smart Power Fab with the microVEGA FC laser-trimming system.

Both companies share a goal of installing 3D-Micromac AG’s laser-trimming systems at more of Infineon’s production sites. The first ordered system, designed specifically for Infineon, will be installed at its Smart Power Fab for use in the production of analog/mixed-signal technologies and power semiconductors.

The order was preceded by a joint-development project in which 3D-Micromac’s lasertrimming process was transferred into a mass-production-capable laser system. The basis for the new solution was the microVEGA system – a system that has already been utilized successfully to process up to 300-mm (12-inch) semiconductor wafers in several industrial use cases.

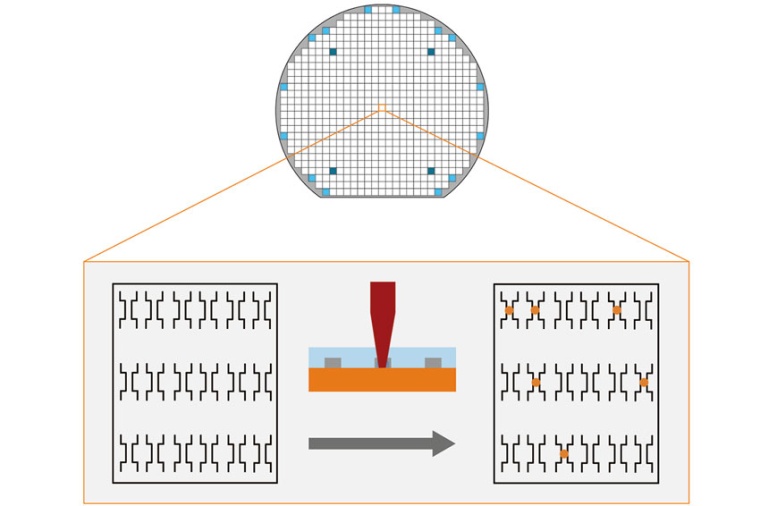

The laser beam of the microVEGA FC is shaped in the single-digit micrometer range and moves continuously over semiconductor chips. During this motion, the laser selectively processes defined microstructures of several dies. This trimming process adjusts the resistance value in individual IC chips to a target value. The small size of the dies’ structures (approximately 1 – 2 µm) and the resulting extremely high demands on the threedimensional positioning accuracy of the laser spot in relation to the structures place the highest demands on the machine hardware. The microVEGA FC includes an integrated measuring technology to achieve 100-percent process control, overcoming a particular challenge in semiconductor laser-trimming applications. The microVEGA FC system features fully automatic handling for 200 and 300-mm wafers. At process speeds of up to 400 mm/s, the system achieves a positioning accuracy of ±200 nm (at 3 sigma).

Infineon plans to begin manufacturing analog/mixed-signal technologies and power semiconductors in Dresden's Smart Power Fab in the fall of 2026. The interaction of power semiconductors and analog/mixed-signal components enables particularly energy-efficient and intelligent system solutions commonly used in power supply systems, such as energyefficient chargers, smaller engine control units for cars, data centers, and Internet of Things (IoT) applications.

Further reading: Hans-Ulrich Zuehlke, Mandy Gebhardt (both: 3D-Micromac): Cost-Effective Production of Integrated Monolithic Sensor Packages – Selective laser annealing enables the setting of different reference magnetization directions on sensors, PhotonicsViews 18(2), April/May 2021, 32-35, first published: 14 April 2021; DOI:

10.1002/phvs.202100032

Company

Infineon Technologies AGAm Campeon 1-15

85579 Neubiberg

Germany

most read

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.