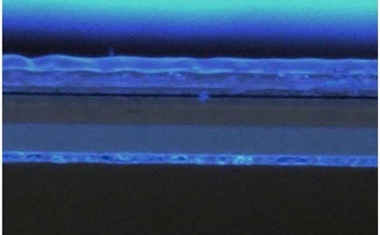

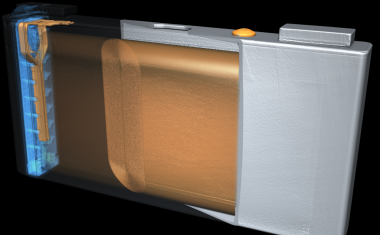

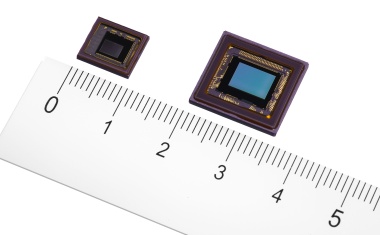

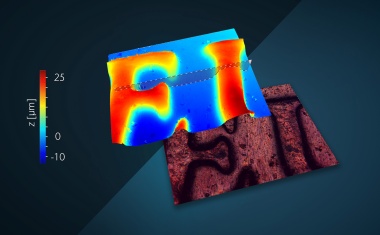

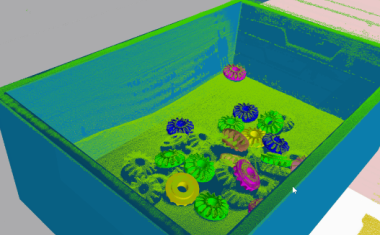

One of the factors that contributes to the recent considerable reduction in the size and high integration of electronics and other devices it is the miniaturization of the electronic components that they contain. In addition, new fine functional materials have been developed and widely used in industrial fields including the automobile, aviation, metal, and chemical industries. As a result, higher accuracy and resolving power are required for minute three-dimensional measurement of these components and materials. Although a variety of devices are available to satisfy these requirements, the confocal microscope is gathering attention as the device of choice for easy three-dimensional, non-contact surface profile measurements in air.