Additive manufacturing of metal becomes more efficient, and sustainable

AI-driven beam shaping and multispectral imaging combined

The EU project “Inshape” developed a new method for optimizing powder bed fusion of metals (PBF-LB/M), combining AI-controlled beam shaping with multispectral imaging. Over three years, the consortium tested the approach on five industrial demonstrators from aerospace, energy, and mechanical engineering. Results included increased production rates, reduced costs, and lower energy and material usage.

Although powder bed-based additive manufacturing of metals is now a key technology for the production of complex metal components, rigid laser beam profiles and inadequate process monitoring methods often cause problems in the melting process and can lead to material defects and production stoppages. This causes scrap, increases energy consumption and production costs, and slows down the production process. The consortium of the EU project Inshape has taken up these challenges and developed a manufacturing approach in its research work that combines AI-controlled beam shaping and multispectral imaging.

Productivity increased sixfold

The Inshape project partners have succeeded in significantly increasing the productivity of the PBF-LB/M process. In various industrial applications, they achieved productivity increases of over 600 percent (6.2x), including production rates of up to 93.3 cm³/h for Inconel 718 components. The original production rate was 15 cm³/h. At the same time, the consortium managed to reduce costs by 50 percent, thereby achieving an important project goal.

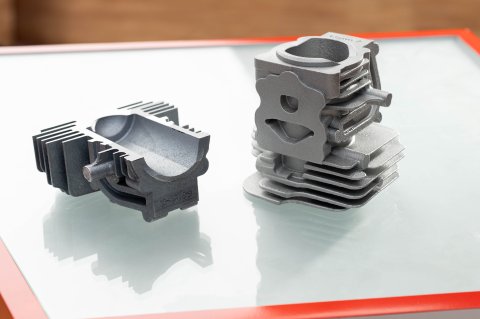

The project partners demonstrated the innovation of beam shaping and multispectral imaging (MSI) in five industrial applications: an impeller for aerospace (Inconel 718), an industrial gas turbine component (Inconel 718), a component of a space combustion chamber (CuCrNb), a cylinder head for a chainsaw engine (AlSi10Mg), and components of satellite antennas for space communications.

AI-controlled beam shaping and multispectral

Intelligent beam shaping and multispectral imaging work closely together to improve the additive manufacturing process. The laser beam profile is adapted to the specific component, taking into account its geometry and material. This improves the quality of the component and enables faster processing by reducing defects such as cracks, spatter, and condensation, which would otherwise cause rework and/or scrap. Inshape‘s research has shown that a ring-shaped beam profile—in combination with optimized scanning strategies—is particularly advantageous for a wide range of applications. The laser energy is deliberately applied not by means of a Gaussian profile, but via a ring-shaped intensity distribution in order to create the melt pool. This results in a more stable melting zone and more uniform material processing.

For this, the new multispectral imaging system records signals in different wavelength ranges and monitors the PBF-LB/M process in real time. This enables thermal changes in the melt pool to be detected at an early stage. The recorded data flows directly into the process control system. Errors that previously led to production interruptions or rework can now be corrected, allowing the process to continue without significant delays.

Paving the way for industrial introduction of series production

Overall, this approach marks an important step forward on the road to industrial series production with PBF-LB/M: The interaction of intelligent beam shaping and MSI-based process control leads to a more stable melting process, reduces sources of error, and enables targeted, resource-saving use of energy. This enables complex metal components to be produced faster, more cost-effectively, and more sustainably—while delivering higher quality and significantly increased productivity. Inshape is thus paving the way for the accelerated industrial introduction of AI-controlled beam shaping and MSI-based process control and strengthening technological progress in additive manufacturing – especially for the aerospace, energy, and automotive industries. „There is a great deal of interest in our work from both academia and industry. We look forward to seeing this technology incorporated into industrial systems in the near future, leading to advances in process control, quality assurance, and application performance in various sectors,“ said Inshape coordinator Prof. Dr. Katrin Wudy from the School of Engineering and Design at the Technical University of Munich.