Surface Inspection in Real-time

Before further processing, the quality of castings' surfaces has to be controlled. For this task, the measurement methods which are available on the market are either too slow for online use or not sufficiently flexible for frequent product changes, says Edixia, the provider of inspection systems. Thus, the company offers a technology which scans all surfaces of a product during the production run and analyses the 3D images thanks to an image analysis program. This way surface inspections as well as geometry measurements can be performed in real-time; results are available immediately in order to take corrective actions upstream. The machine vision solution is also suited for the continuous optimization of manufacturing processes.

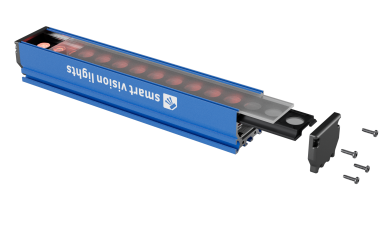

Edixia offers its frame grabbing and image processing technology within the product range 3dCast. It is based on the principle of laser triangulation and consists of a laser beam projector, a system of sensors, patented optics for avoiding shadow effects and an optical filter to eliminate reflections. The system's measurement resolution is determined by three coordinates: camera axis, movement axis and triangulation axis.

Overall Profile of Multiple Scans

Since it is usually necessary to check more than one side of a foundry product, 3D-Cast technology enables several sensors to be used at the same time for different sides. In this case, sensors are calibrated relative to each other within the machine so that they all work within the same system of coordinates. With this type of arrangement, all scanned contour lines can be combined into a single overall profile. This is achieved by creating a scatter of points in which each point represents the component's visible X, Y and Z coordinates, with a maximum resolution of 10 µm.

In addition, the application provides various log files. All results are saved in a statistical database. Implemented statistical checks are then carried out, including six sigma, control point histograms and trend analysis.