“USP lasers revolutionize battery and hydrogen technology”

Review: 6th UKP-Workshop: Ultrafast Laser Technology, 21 – 22 April 2021, Aachen, Germany.

Ultrafast lasers have become a standard manufacturing tool for the display industry, with even more and even larger applications coming in the next few years. The technology and processes needed for these new applications were presented at the 6th “UKP-Workshop: Ultrafast Laser Technology”, held by the Fraunhofer Institute for Laser Technology ILT. Their spectrum ranged from ultrapowerful beam sources to processes that can be used to enlarge the surface of a metal electrode, for the generation of hydrogen, a thousand times.

Every two years since 2011, experts for ultrashort-pulsed lasers have been meeting in Aachen to exchange ideas and discuss trends from industry and research in a personal atmosphere. This year, the networking event took place online. Fraunhofer ILT made a virtue out of necessity and used the opportunity for virtual laboratory tours, which were previously not feasible at a live event since so many participated in the past.

The core topics of the UKP-Workshop, so the German name, include developments in beam sources, process knowledge and potential applications. In the tenth year of this workshop series, there was again considerable progress to report in all these fields.

USP lasers for the energy of the future

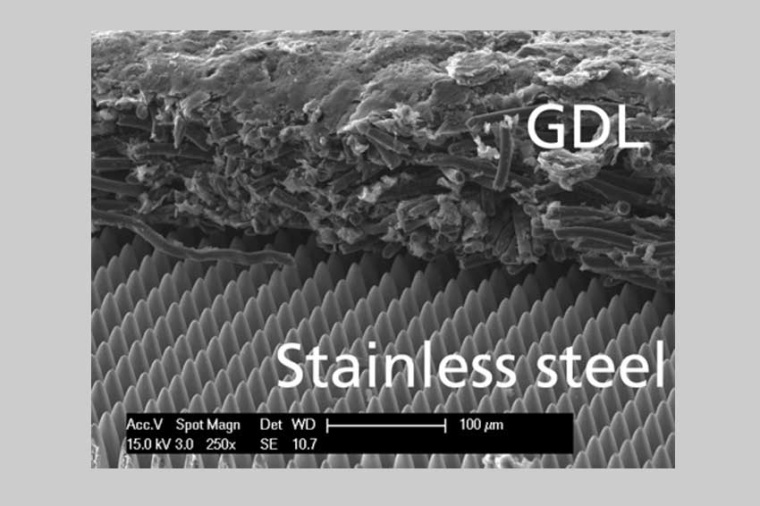

Battery and hydrogen technologies make up a very large emerging sector in which USP lasers can be applied. In his presentation, Dr Karsten Lange from Fraunhofer ILT showed both the environment and concrete examples of this. In hydrogen technology, there are several starting points. The most impressive is certainly the enlargement of the effective electrode surface by a factor of 1600 through laser structuring, which the scientist was able to achieve.

Battery technology today is all about increasing both energy density and power density and laser processes are being developed to advance both fields. At high power densities (i.e., fast charging or discharging processes), lithium separation is currently an issue. The USP laser can be used to introduce micropores into the electrodes of the batteries, thus mitigating the problem. The technology will be investigated at Fraunhofer ILT in a special battery laboratory starting in summer 2021. Crucial to the widespread introduction of USP lasers into battery and fuel cell manufacturing will be the power scaling of the beam sources. For superior productivity, USP lasers with 5 to 10 kW are needed here.

7th “UKP-Workshop: Ultrafast Laser Technology” – Outlook for 2023

USP lasers have caught on in the industry, but the current UKP-Workshop also showed how much process knowledge is still being developed to bring the full potential to manufacturing. “The ultimate goal would be a universal digital laser milling machine that could handle a wide range of machining tasks” is how workshop organizer Prof Arnold Gillner summarized the vision.

High repetition rates, high power and how to get the power efficiently onto the workpiece – these are keywords that will certainly play a role at the next UKP-Workshop on April 26 and 27, 2023 in Aachen. “Then hopefully we will meet again in person,” co-organizer Martin Reininghaus concluded, expressing the wish of all participants. (Source: Fh.-ILT)

Company

Fraunhofer Institute for Laser Technology ILTSteinbachstr. 15

52074 Aachen

Germany

most read

Basler AG: Change in the Management Board and new CTO position

Long-time CEO Dr. Dietmar Ley will leave the Executive Board at the end of 2025

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Purdue University, Rittal and Eplan work together

As part of this partnership, Purdue will open two exclusive laboratories.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.