Laser cleaning – underwater

The LZH, Laserline, and Fraunhofer IFAM, have developed a laser process to clean ship hulls.

Biofouling is the growth of algae, mussels, and other marine organisms on the hull of a ship. The fouling increases the flow resistance of the ship – and thus increases fuel consumption and CO2 emissions. Mechanical cleaning of the fouling can damage the hull coating. In addition, the fouling must be extracted if organisms or even parts of the ship's coating are not to get into the water. Scientists from the LZH, together with Laserline and the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research IFAM, have now developed an environmentally friendly and efficient solution to the problem of biofouling.

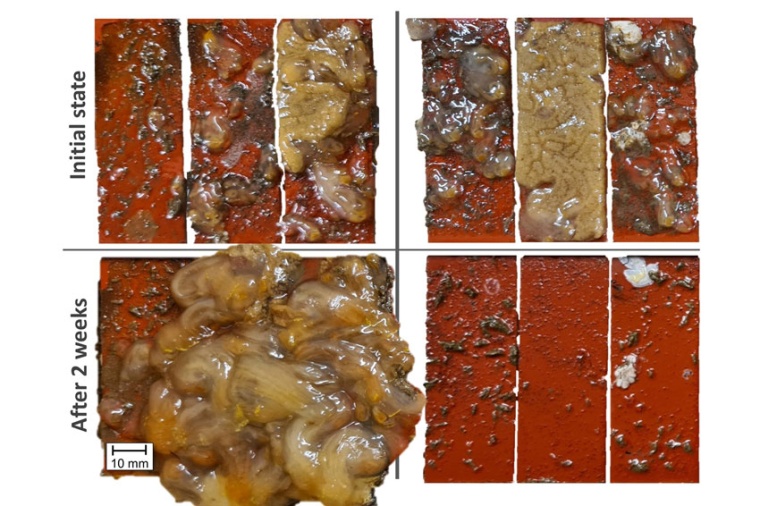

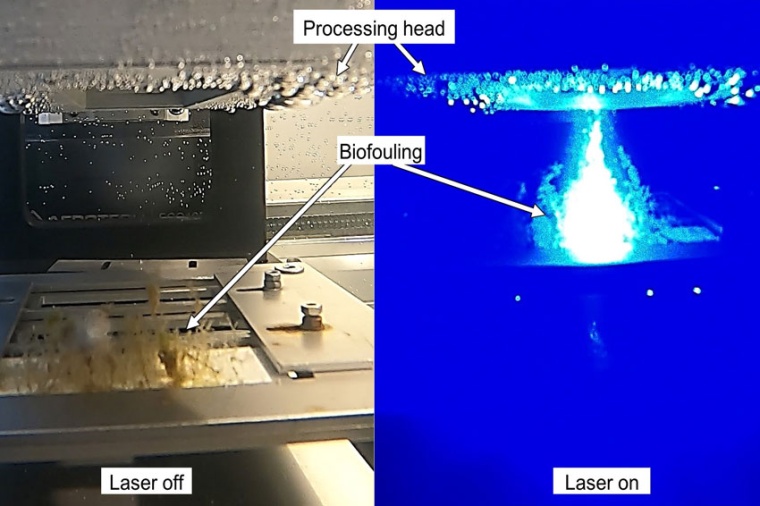

Laser radiation can be used to lethally damage marine fouling underwater without damaging the underlying coating of the ship’s hull. The LZH scientists have developed a process in which the cells of the fouling are damaged by laser radiation in such a way that the fouling dies and is then simply washed away by the water after some time.

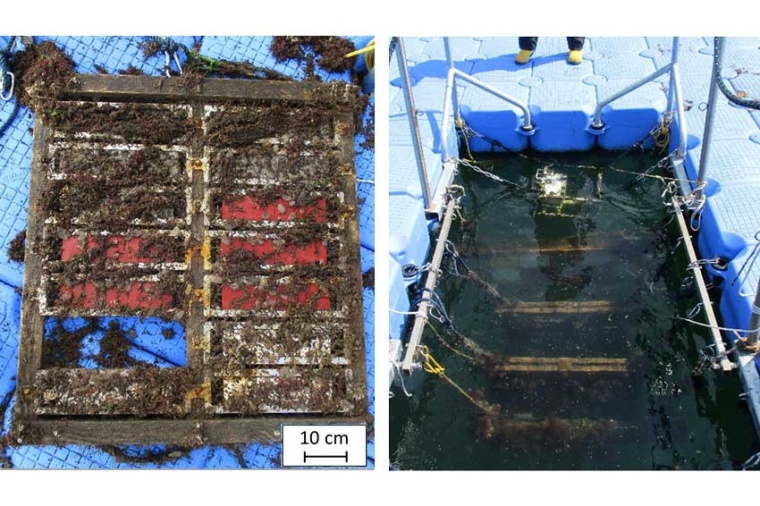

The researchers conducted their investigations in the south harbor of the island of Helgoland. There, they irradiated fouling samples with the laser, then returned them to the North Sea and checked them after two to four weeks. “We were able to achieve a clear, time-delayed cleaning effect,” says underwater technology expert Dr-Ing Benjamin Emde from the LZH. “With simulated currents, as would be added in real life with a moving ship, the cleaning effect is further enhanced.”

And biofouling is not only a problem for reasons of fuel consumption and emissions: the fouling can lead to the introduction and spread of non-native species in foreign ecosystems. “Species displacement is a major risk of biofouling,” Emde says. If a ship introduces foreign organisms into an ecosystem through hull fouling, it can severely disrupt the ecosystem. In practice, this leads to ships being banned from docking in foreign ports, as has happened again recently with cruise ships, for example. Here, as well, cleaning with the laser is a good alternative to mechanical methods: Because the introduced biomass is lethally damaged during laser cleaning, it is no longer dangerous for foreign ecosystems.

Company

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAMWiener Straße 12

28359 Bremen

Germany

most read

Basler AG: Change in the Management Board and new CTO position

Long-time CEO Dr. Dietmar Ley will leave the Executive Board at the end of 2025

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.