Laser-blanking system to cut costs

The new TruLaser 8000 Coil Edition is a flexible, high-volume cutting solutions “straight from the coil”, saving up to 1,700 tons of steel worth some 1.6 million euros per year.

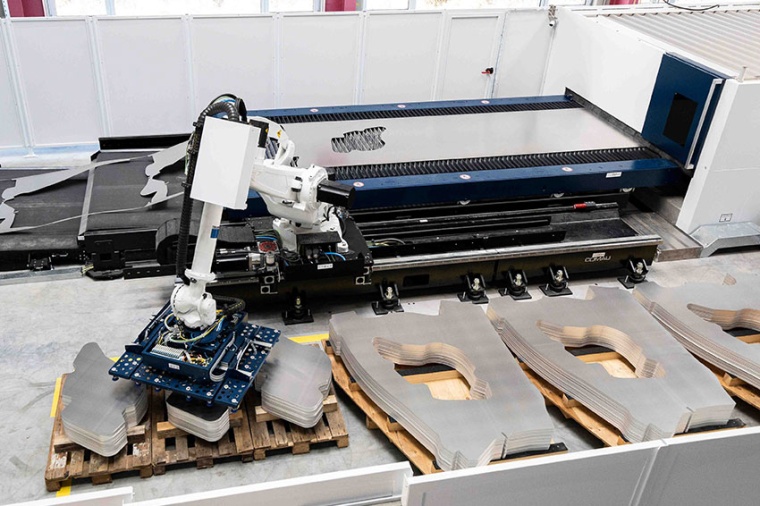

High-tech company Trumpf will be launching a new laser-blanking solution at its Intech in-house trade show in March 2023. The TruLaser 8000 Coil Edition can process up to 25 metric tons of coiled sheet metal from start to finish without any human intervention. It is an attractive option for any company interested in flexible, high-volume solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers and HVAC manufacturers.

“The TruLaser 8000 Coil Edition is another example of Trumpf helping its customers to join the drive toward greater sustainability in the manufacturing industry while simultaneously boosting efficiency. Compared to conventional laser-cutting machines, the solution allows companies to save almost 1,700 metric tons of steel a year, which equates to a saving of some 4,000 metric tons of CO2 and a reduction in material costs of 1.6 million euros,” says Richard Bannmüller, CEO at Trumpf Laser Technology Germany.

Thanks to this new laser-blanking system, companies can enjoy the benefits of laser processing even in high-volume production environments. “Volume manufacturers often use presses for blanking operations. But that means they need to adjust or even replace the tool whenever they make the slightest modification to their components, which ultimately costs time and money. Many industrial sectors are seeing significant reductions in the scale of individual production runs, which makes these modifications even more costly and time-intensive. The laser allows users to carry out these modifications without requiring a new tool, so it’s much, easier, faster, cheaper and more flexible,” says project manager Oliver Müllerschön, who is responsible for the new system at Trumpf.

The high-tech company developed the new system in cooperation with Siemens and mechanical engineering company Arku. Together with Trumpf, Siemens is responsible for the control system and Arku for the coil system. The Fischer group in Achern is one of the first companies to put the new solution into practice. “Deploying a laser-blanking line is a new approach for us. It offers huge benefits to our production process, partly due to its high flexibility and quality, but also thanks to the fact that we require hardly any tools compared to conventional blanking presses,” says CEO and owner Hans-Peter Fischer. His company is an early adopter of Trumpf’s laser-blanking system, which it uses to produce high-strength aluminum structural components for vehicle-body manufacturing.

Coil production enables users to achieve more efficient nesting of parts. Conventional sheets are limited by their four outer edges, which often make it difficult for production workers to make full use of the entire sheet. Unused sections of the sheet either have to be discarded as scrap or melted down. A coil, which can be up to 1.5 kilometers long, solves this problem by allowing users to nest an almost endless number of parts on the sheet.

This reduces material consumption by around fifteen percent. Compared to conventional blanking presses, the new system also heralds a significant reduction in construction and logistics costs. It makes production more profitable by eliminating tooling costs, optimizing the use of material, reducing assembly costs and boosting flexibility in the production environment.

The material flow is different to that of conventional 2D laser machines, leading to much lower cycle times and new automation opportunities for high-volume production series. The system can be flexibly adapted to any contours. It is designed for thin-sheet processing and can handle sheet thicknesses of up to 6.5 millimeters.

Company

TRUMPF SE + Co. KGJohann-Maus-Straße 2

71254 Ditzingen

Germany

most read

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

Basler AG: Change in the Management Board and new CTO position

Long-time CEO Dr. Dietmar Ley will leave the Executive Board at the end of 2025

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.