Better results for skin cancer surgery

Fluorescence imaging helps improve outcomes in head and neck skin cancer treatment – at reduced cost.

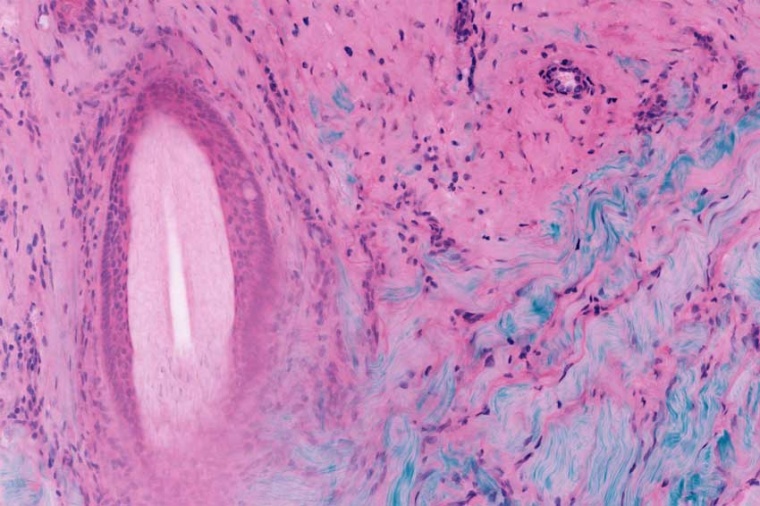

Mohs skin surgery can bring a permanent cure to skin cancers, when other methods have failed. Complete surgery and repair of the surgical site is normally a same day operation. However, Mohs is slow and extremely labor intensive because it depends on frozen sections processing to produce histological images. The cost and reduced throughput associated with frozen section processing limits its availability to patients while contributing to rising health care costs. University of Rochester professor Michael Giacomelli and his team want to solve this problem by using fluorescence microscopy.

Prof Giacomelli recently received NIH funding for his project named “Fluorescence microscopy for evaluation of Mohs surgical margins”. His research objective is to enable real-time evaluation of pathology in skin tissue with an order of magnitude reduction in processing time as compared to frozen sections.

The most common forms of cancer worldwide are basal cell carcinoma and squamous cell carcinoma. And their incidence is showing a rapidly increasing trend in the last years. Mohs surgery is a widely used technique for the treatment of nonmelanoma skin cancer that obtains extremely low recurrence rates by imaging tissue as it is removed from the body to ensure complete resection. Mohs micrographic surgery is a specialized technique to remove non-melanoma skin cancers.

Lasers enable clinical imaging of pathology in living human tissue

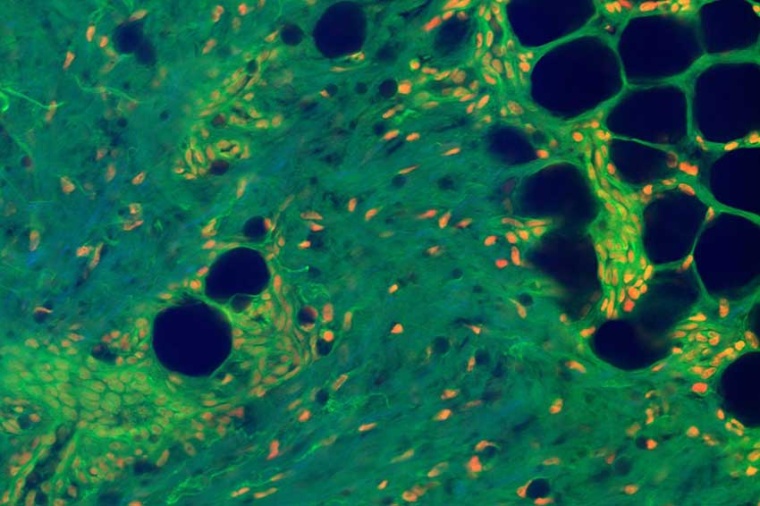

Giacomelli developed a way to image multiple depth slices without frozen section processing – by implementing two-photon imaging, widely used in the neurosciences to noninvasively image slices at different depths in living brains. The lab team’s research has adapted these fluorescence imaging technologies with rapid tissue labeling and image processing technologies. This enables real-time assessment of pathology in skin tissue. processing time compared to frozen sections has been reduced by an order of magnitude. The data collection time is further reduced using the lower-noised silicon photomultiplier detectors developed by Giacomelli’s group.

2-photon fluorescence microscopy can provide rapid point-of-care diagnosis of non-melanoma skin cancer through real-time imaging of fresh tissue biopsies.

The femtosecond laser system (a FemtoFiber ultra 920) chosen for the next iteration of the Giacomelli lab’s microscope is a possible solution for applications in nonlinear microscopy like two-photon excitation of fluorescent proteins and SHG based contrast mechanisms. With an emission wavelength of 920 nm, it provides the highest peak power for imaging with green and yellow fluorescent protein markers (GFP, YFP) commonly used in pathology, neurosciences and other laser-related biophotonic disciplines. Researchers appreciate the usability of the system since it is both, maintenance free and very compact.

Company

TOPTICA Photonics Inc.1120 Pittsford Victor Road

Pittsford, NY 14534

US

most read

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Basler AG: Change in the Management Board and new CTO position

Long-time CEO Dr. Dietmar Ley will leave the Executive Board at the end of 2025