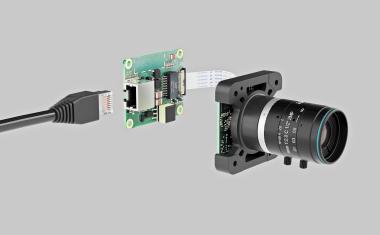

Smart Camera for Machine Vision Inspection

Dalsa announced today the availability of a high resolution model of its Boa vision system, a highly integrated smart camera that comprises all of the elements of an industrial machine vision system. The new Boa M1280 offers high image quality at a resolution of 1,280 x 960 and operates at up to 24 frames per second.

"High resolution sensors provide greater measurement accuracy and are able to distinguish very small features that, if missed, could render a product defective," says Steve Geraghty, director of Dalsa Industrial Products. "High resolution imagery, combined with the processing capabilities of the Boa smart camera, offers manufacturers of all industries a capable inspection solution at an affordable price."

Dalsa's Boa is an all-in-one machine vision solution that is easier to use and more flexible than previous generations of smart cameras. The smart camera incorporates multiple processing engines. This enables algorithm optimization via DSP, application management via CPU, and sensor management via FPGA. It is also offers truly embedded application software, which is easily set-up through a standard web browser. There is no software to install, and therefore no version control problems. Boa delivers greater flexibility for its users via a rugged, easy-to-mount enclosure, built-in factory communications, and a low deployment cost.

The monochrome version of the new high-resolution Boa vision system, Model M1280, is available immediately. A complementary color version will be available later in the year.