New Vision and Multi-Sensor Measuring Systems

Hexagon Metrology is introducing a wide range of vision and multi-sensor measuring systems to the market under the Optiv label. Five series are available - from the basic model to a high-performance instrument for measurements on the nano-scale.

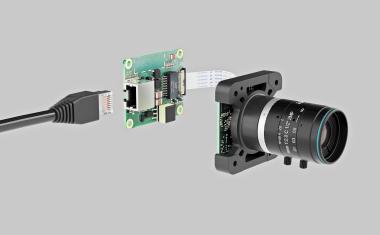

The multi-sensor technology in the Optiv product range combines optical and tactile measurements in one system. Set up for 2D or 3D geometry, the system carries out measurements using the most suitable sensor, depending upon the material, reflection characteristics and accuracy requirements of the inspected item, with or without contact. Optiv supports multi-sensor measurements using video sensors, tactile sensors, Through-the-Lens lasers (TTL-lasers) as well as the innovative Chromatic White Light Sensors (CWS).

"One great advantage we can offer our customers is the measurement software PC-DMIS Vision," says Mario Schroeder, Product Manager of the Optiv line. "Through the use of this leading measurement software solution on all Optiv measuring machines we have implemented a uniform operating philosophy to considerably reduce the training requirement. PC-DMIS has been considered the standard application when it comes to CAD-based measurement software. PC-DMIS Vision now allows all the impressive functions for data capture and analysis to be used in vision metrology."

Optiv measuring systems are perfectly designed for the quality assurance of components in the automobile and aerospace industries, telecommunications and biomedical engineering, plastic and electronics industries, microsystems technology, as well as in tooling and mould making. These measuring machines can be used to test the dimensional integrity of items such as integrated circuits, medical implants, micro-lenses or ball grid arrays.