Laser Seam Inspection with the innovative HDR-HR sensor

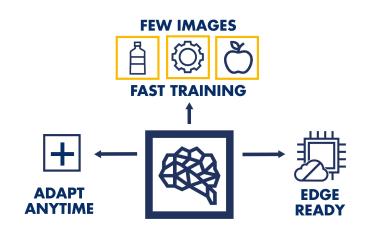

Viro WSI automated weld seam inspection systems help automotive manufacturers & suppliers ensure that components are inspected precisely, objectively, and efficiently 24/7, and that the quality is automatically documented. It is equipped with the well-established HDR sensor for MIG/MAG seam inspection, and Vitronic has now added an HDR-HR sensor to the Viro WSI weld seam inspection system, which also inspects fine laser and brazed seams inline at 6m/min and with an exceptionally high degree of accuracy. Laser beam welding is characterized by a fast weld speed and narrow seam geometries.

Common applications are large-scale bodywork production, tailored blanks and battery production. This new sensor offers an extremely high resolution and is already used successfully by renowned OEMs and suppliers. Vitronic's automated inspection solution also boasts user-friendly, intuitive software.