Better optical fibers under high pressure

Silica glass fibers manufactured under high pressure could cut signal loss in half.

Optical fiber data transmission can be significantly improved by producing the fibers, made of silica glass, under high pressure, researchers from Japan and the US report. Using computer simulations, researchers at Hokkaido University, The Pennsylvania State University and their industry collaborators theoretically show that signal loss from silica glass fibers can be reduced by more than 50 percent, which could dramatically extend the distance data can be transmitted without the need for amplification.

“Improvements in silica glass, the most important material for optical communication, have stalled in recent years due to lack of understanding of the material on the atomic level,” says Madoka Ono of Hokkaido University’s Research Institute of Electronic Science (RIES). “Our findings can now help guide future physical experiments and production processes, though it will be technically challenging.”

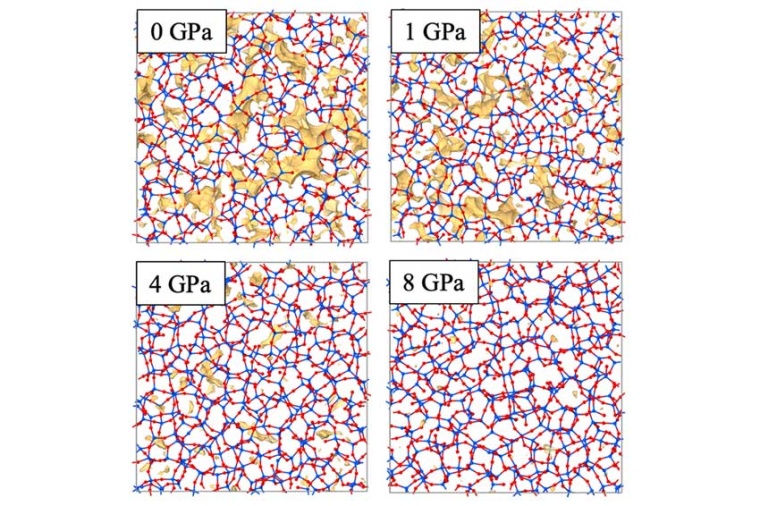

The data signal in optical fibers peters out before reaching its final destination due to light being scattered. Amplifiers and other tools are used to contain and relay the information before it scatters, ensuring it is delivered successfully. Scientists are seeking to reduce light scatter, called Rayleigh scattering, to help accelerate data transmission and move closer towards quantum communication. Ono and her collaborators used multiple computational methods to predict what happens to the atomic structure of silica glass under high temperature and high pressure. They found large voids between silica atoms form when the glass is heated up and then cooled down, which is called quenching, under low pressure. But when this process occurs under 4 gigapascals, most of the large voids disappear and the glass takes on a much more uniform lattice structure.

Specifically, the models show that the glass goes under a physical transformation, and smaller rings of atoms are eliminated or pruned allowing larger rings to join more closely together. This helps to reduce the number of large voids and the average size of voids, which cause light scattering, and decrease signal loss by more than 50 percent. The researchers suspect even greater improvements can be achieved using a slower cooling rate at higher pressure. The process could also be explored for other types of inorganic glass with similar structures. However, actually making glass fibers under such high pressures at an industrial scale is very difficult.

“Now that we know the ideal pressure, we hope this research will help spur the development of high-pressure manufacturing devices that can produce this ultra-transparent silica glass,” Ono says. Madoka Ono is part of the Laboratory of Nanostructured Functional Materials, RIES at Hokkaido University. Her research focuses on the properties of non-organic and silica glass by both laboratory experiments and computational analyses. (Source: Hokkaido U.)

most read

United Robotics Group restructures

The company focuses on the healthcare industry and innovation.

ZVEI survey: Significant investments in industrial AI planned

A recent survey by the ZVEI shows that the manufacturing industry in Germany wants to invest significantly in industrial AI.

Successful conclusion of the IVSM Fall Meeting 2025 in Haikou, China

The 2025 Autumn International Vision Standards Meeting (IVSM) took place from November 3 to 7 in Haikou, Hainan, and attracted over 120 R&D engineers worldwide.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

SEW-Eurodrive and TTTech Digital Solutions enter into partnership

The aim of the collaboration is to integrate SEW-Eurodrive's axis and drive systems into the Ubique automation platform.