75 years of SAB Bröckskes in Viersen

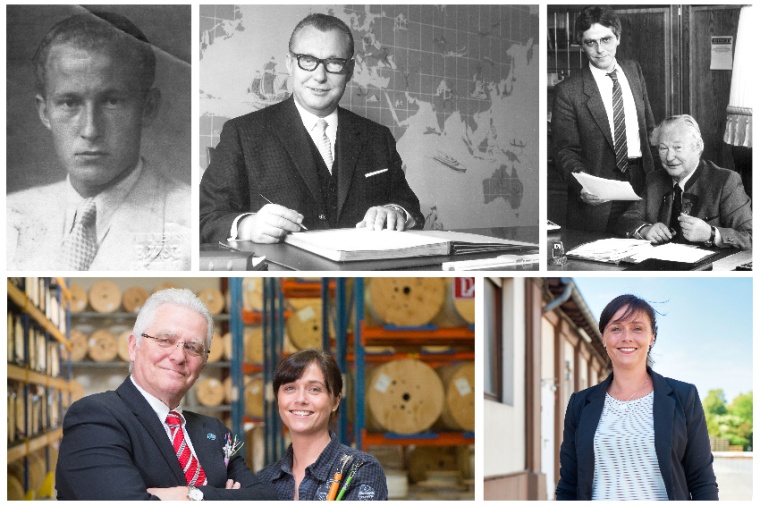

The company history of SAB begins in 1947 with Peter Bröckskes senior. and a workshop in a shed in Süchteln as well as a "capital" of 100 Reichsmarks.

In 1985, the annual production length of electrical cables already reached once around the world. Exactly ten years later, SAB Bröckskes expands its product range with plug and play solutions and positions itself as a cable and wire assembly company.

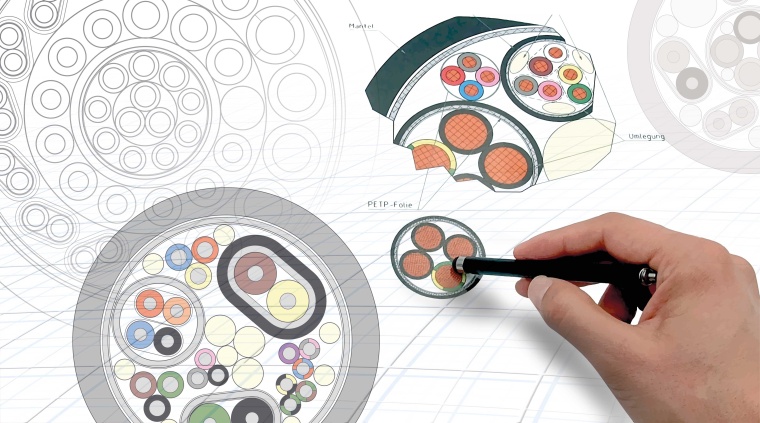

When it became increasingly difficult to remain competitive with products "Made in Germany" in the 1990s, the company showed itself to be flexible again. The competition for cables and wires is becoming increasingly acute. In addition, more and more cable manufacturers are relocating their production sites to the East, resulting in a drop in the price of standard cables. Initially, this represents a crisis for SAB Bröckskes. However, Peter Bröckskes uses the crisis as an opportunity and makes a momentous decision and heralds a change in strategy.

To date, 95 percent of the products have been standard cables that have been manufactured and sold in large quantities. From now on, SAB concentrates on the production of special cables. "We do everything that the big players in our industry can't do," explained Peter Bröckskes. From today's perspective, a courageous decision that turned out to be the right one.

The new corporate strategy envisages supplying directly to industry instead of to retailers and to emphasizing the strengths of a medium-sized family business: flexibility, technical competence and short decision-making processes. These are the optimal conditions for responding individually to each request. In this way, SAB Bröckskes can remain in Germany as a production location, secure jobs and establish itself as a problem solver in the industry.

The company received its current name in 1998, replacing the old company name Signal-Anlagen Peter Bröckskes. At this time, the well-known circular logo was created, which reflects the three product areas of cables & wires, measurement technology and cable assembly. In 2018, the logo will be expanded to include the addition Special Cables, as this is exactly where the expertise of the Viersen-based company lies. As a manufacturer of special cables, SAB has successfully managed to get the corona pandemic over with and promotes digitization in the company. In addition, it secures all jobs with innovations and investments.

With Sabine Bröckskes-Wetten succeeding her father, Peter Bröckskes, the third generation is already mastering the crises of their time. Today, SAB Bröckskes is one of the world's leading cable manufacturers with more than 550 employees and sales of more than 134 million euros in more than 100 countries. "Today, we are represented on the market with numerous products and thus actively contribute to the success of companies in a wide variety of industries," explains Sabine Bröckskes-Wetten, Managing Director of the SAB Group.

“We are leaders above all in the construction and development of customer-specific cables, so-called special cables. And we can do that particularly quickly. It is not for nothing that we are known as the “speedboat” of the cable industry. Made in Viersen stands for quality, flexibility and innovative strength and will also hold its own in the coming decades. In the anniversary year, we are therefore particularly proud of the performance of our employees, many of whom have been with us on our path for more than 25 years,” says the managing director.”

Company

SAB Bröckskes GmbH & Co. KGGrefrather Str. 204-212b

41749 Viersen

Germany

most read

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

Physik Instrumente supports space research

The company is providing 2,500 hybrid actuators for the Extremely Large Telescope (ELT)

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.