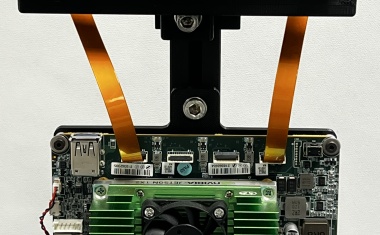

How to build a custom embedded stereo system for depth perception

This article first describes the main parts of a stereo vision system and then provides instructions on making an own custom stereo camera using off-the-shelf hardware components and open-source software. As this setup is focused on being embedded, it will compute a depth map of any scene in real-time, without the need of a host computer.