Smart Camera for quality monitoring, process control, or identification of parts on production lines

The Visionscape Smart Camera (formerly HawkEye 1600T) combines a compact form factor with the broad applicability, versatility and proven performance of Visionscape software. Designed for use in a wide range of applications, the Visionscape smart camera provides a cost-effective, easily deployed solution for manufacturers to monitor quality, control processes, or identify and trace parts on production lines.

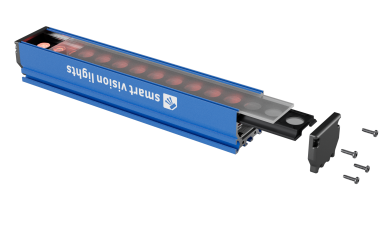

Flexible Configuration

The Visionscape smart camera features C-mount optics and separate lighting, with built-in digital I/O, serial communications, and Ethernet networking. All processing is done on-board using a high performance, embedded CPU.

Visionscape and Intellifind

Integrated Visionscape software offers powerful processing for image transformation and analysis, including high-level tools for character verification (OCR and OCV), and reading and verifying a wide range of barcodes. The optional Intellifind tool provides robust object finding and pattern recognition.

Rugged Design

With a cast alloy IP67 en-closure and M12 connectors, the Visionscape smart camera is an ideal choice for the toughest industrial applications.

Application Examples

► Assembly verification (automotive, medical devices, packaging)

► Print quality inspection (pharmaceutical, other)

► Package quality inspection (food and beverage)

► Component presence/absence checking (electronics)

► Part location (robotics, machine builder)

► Part identification (automotive, electronics, packaging)