Humanoid robotics requires dexterity

The hand is perhaps the most utilized human tool. Its dexterity, fine motor skills and sensory feedback make it the interface between the body and the environment. Reproducing this fascinating functionality in an artificial hand is one of the greatest challenges in robotics, and at the same time one of its most difficult tasks. Whether in automation or medical robotics, industrial applications or modern prosthetics - robotic hands are expected to do what the human hand has perfected over thousands of years: coordinate complex movements, use different gripping techniques, react to external stimuli and precisely use force. It's not just about shape and mobility, but also about miniature motors, intelligent control and the ability to adapt to changing environmental conditions.

The human hand is a highly complex and finely tuned integration of 27 bones, over 30 joints and muscles as well as numerous tendons for maximum flexibility and control. For an artificial hand, this means that it must be designed to be robust and flexible, light and stable, as well as compact and efficient. It is a balancing act that places high demands on materials, design, and most importantly, drive technology! Electric motors ensure powerful movements, sensors provide the necessary feedback and intelligent control systems coordinate the processes in real time. In short, for a robotic hand to move as human-like as possible, it needs a precision, and finely tuned inner components . The aim is to create a symbiosis of technology and biology – helping to restore losts of abilities or to expand human capabilities. The transition between humanoid robotics and modern prosthetics is fluid. Both disciplines use similar technical principles to enable movements that come as close as possible to the human model.

Fine motor skills

Humanoid robots form the transition between artificial intelligence and the real, physical world. Their hands are not just tools but means of expression and interaction. The quality of the motion sequences - how smoothly, powerfully or precise they are executed - depends largely on the underlying drive technology. Miniaturization, precision, dynamics and energy efficiency are not just buzzwords, but key success factors. Only when these elements interact perfectly is it possible to make movements appear so natural that the difference between the human and robots is barely noticeable. High energy efficiency plays a particularly important role, as space and energy sources are limited and the drive still has to function reliably.

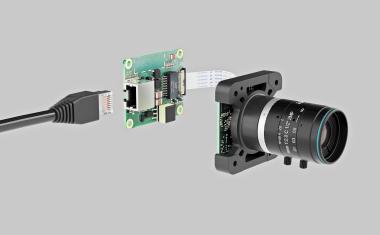

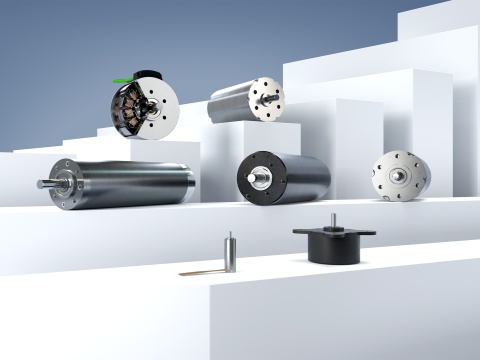

In order to be able to move the fingers of a robotic or prosthetic hand individually, each finger is driven by one or more actuators. More than 20 drives are often used per hand to enable the most complex motion sequences. It goes without saying that the drives, usually consisting of a motor, encoder, planetary gearbox, spindle and controller, must be extremely compact. Only in this way can the fingers be individually arranged into different gripping patterns - from delicate movements to powerful gripping processes. The DC motors from the Faulhaber SXR family are particularly suitable for this demanding application. Thanks to their innovative winding geometry, high-performance rare-earth magnets and the diverse combination options of high-precision planetary gearheads, they offer ideal conditions for use in artificial hands.

A hand full of possibilities

Faulhaber has decades of experience in the development and production of high-precision drive systems and knows the special requirements that robotic hands and modern prostheses place on technology. Micromotors from Faulhaber are used worldwide in high-end medical prostheses as well as in robotic systems. They enable what has long been considered visionary, powerful, sensitive and dynamic movements in the smallest of spaces. Whether in the human body or in a humanoid robot, the quality of every movement begins with the right drive.