A photonic twin of Michelangelo’s David

Laser-scanned and 3D-printed art piece for Expo Dubai

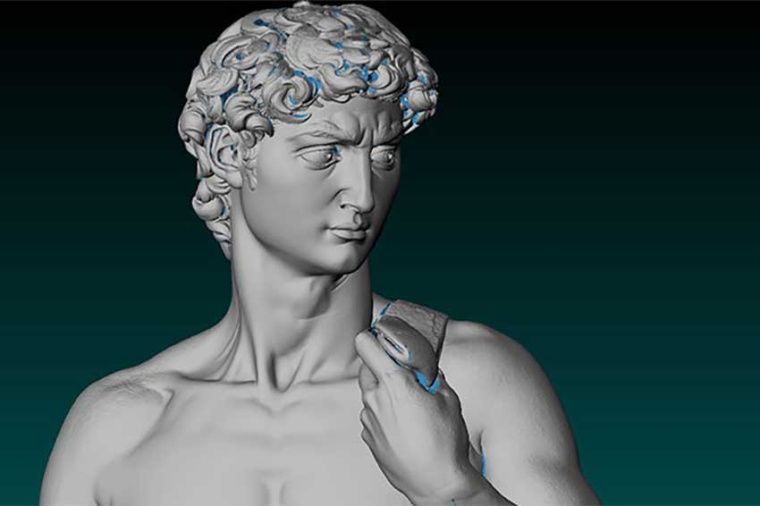

A 3D printed replica of Michelangelo’s famous David sculpture, reproduced with the use of scanning technology by Hexagon, was unveiled in May. during a ceremony at the Italy Pavilion at Expo 2020 Dubai. The so-called David Twin will be the centerpiece of the pavilion’s Theater of Memory.

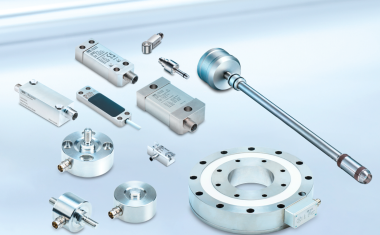

The project to create the replica posed numerous challenges, not least due to the scale of the original, which stands at over seven metres tall and weighs more than five tons. Scanning this iconic sculpture took two people 10 days to complete. Two Hexagon technologies, an AICON StereoScan neo structured light scanner and a Leica Absolute Tracker with handheld scanner, were used to ensure optimum accuracy while managing the scale of the challenge.

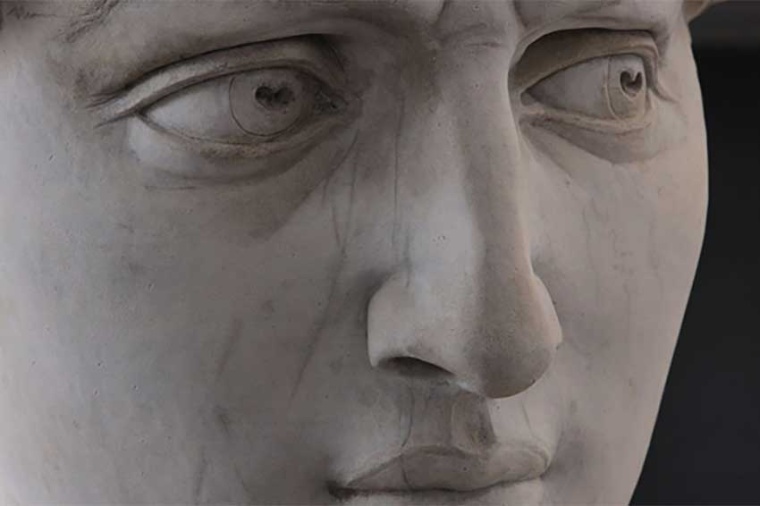

The mix of these two technologies was critical to achieve the best result; the laser tracker, which is typically used to measure precision aerospace components, is able to give high accuracy across large areas and the structured light scanner is able to achieve even higher resolution when focused on small areas. This instrument was used for the particularly detailed elements of the sculpture such as the face and hands. By combining these technologies, the team was able to achieve the optimum compromise of scale and resolution.

Nevertheless, there were a number of additional challenges to overcome. For example, an 80cm distance was required between the scanner and the statue to achieve optimum detail. This was particularly tricky when trying to capture intricate parts. Additionally, given the height of the David the scanners had to be mounted on a stair and raised, after which the team would analyze the picture to check for resolutions and accuracy, and repeat if necessary.

Following David’s appearance at the Expo, the digital twin created by the scanning process will be analyzed to derive additional learnings. The extraordinary detail of the data reveals, for example, the effects of acid rain, dust, and even traces of the different tools used to create it. This information can be used by experts and restorers to preserve the David, and other iconic art pieces, by anticipating and preventing degradation.

It’s also recognized that there may be opportunities for future, more accurate scans of the David and other iconic art pieces. This latest project follows a similar one completed by Stanford University in 1999, which took one month and 22 people to achieve a lower resolution scan. As technology advances it’s hoped that an even higher level of detail can be achieved.

“Scanning the David presented a number of challenges,” says Cesare Cassani, Automation Technologies & Portable Systems Manager, Hexagon’s Manufacturing Intelligence division. “Not only was the scale enormous, but the time constraints were also tight, and we had to overcome a number of obstacles as we went along. Specific parts such as the inside of the hands, and underneath the bent arm, for example, proved particularly challenging, as well as capturing all the dents and imperfections that the David has incurred over the years.” (Source: Hexagon)

Company

Hexagon Manufacturing Intelligence250 Circuit Drive

North Kingstown, Rhode Island, 02852

US

most read

Debra Phillips gives keynote

The NEMA President and CEO will Headline SPS Atlanta 2025 with High-Impact Keynote: “Powering the Electric Future”

Faulhaber opens new sales office in India

The location is strategically embedded in the Asia-Pacific sales region.

20 years of Bernstein Safe Solutions in China

The company celebrates its branch in Taicang as a model of success.

Baumer acquires force sensor specialist

The company is strengthening its position in force and strain measurement by acquiring Swiss company X-Sensors AG, a specialist in high-precision sensors.

Change of management at imec

The company has appointed Patrick Vandenameele as its new CEO.