PARMS coating technology for UV to IR laser applications

A new article in PhotonicsViews discusses the production of high-quality oxides-based optical filters with low losses.

In today’s rapidly advancing world, engineering and functional optical materials have to meet ever-increasing requirements. The development of advanced technologies and materials usually leads to the need to reduce bulk materials to micro and nanometer sizes whose properties are different from those of bulk state. Usually, the formation of multicomponent thin film structure allows to meet the required optical specification.

Since the reactive magnetron sputtering was introduced and applied to the production of thin films in 1974, this technique become one of the most used and efficient technologies for optical coatings production.

Reactive sputtering using a medium frequency (MF) dual magnetron source is an advanced technique widely employed in various thin film deposition applications. For producing high-quality optical filters based on oxides with low losses, it is crucial to exclude any form of arcing, including both strong arcs and microarcs. These requirements are solved by plasma-assisted reactive magnetron sputtering (PARMS), which also provides a high deposition rate contributing to the economically efficient production of high-end optical filters.

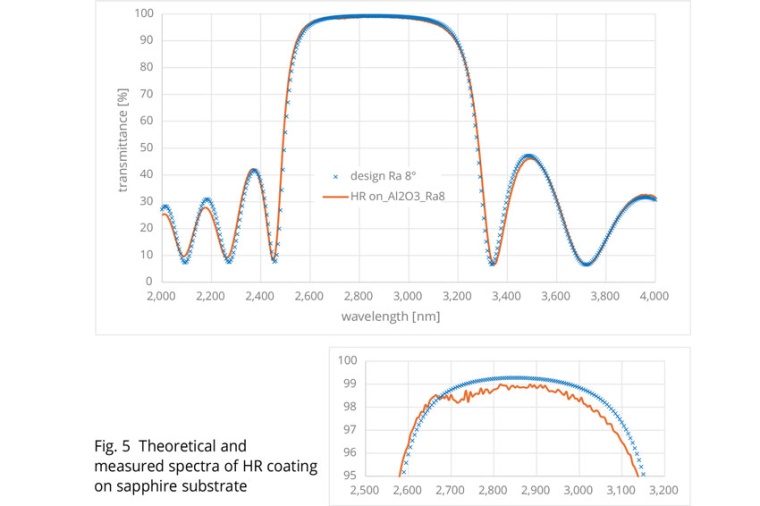

The Meridian sputtering system by I-Photonics has proven its exceptional capability in producing high-quality fully amorphous structures without defects, which effectively prevents moisture penetration in the coatings. This leads to minimal losses in the water absorption region, which is confirmed by the high reflection (HR) of the mid-infrared mirror. The mirror was designed using a pair of materials Ta2O5/SiO2 optimized for the UV and visible ranges were sputtered on quartz (Al2O3) substrate with a central wavelength at 2,850 nm for 0 degrees incidence angle with a total coating thickness of 7.2 μm (Fig. above).

Read the interactive issue in the Adobe Cloud, or download the PDF – Alexander Myslivets, Henadz Rabatuyeu, Nadzeya Khinevich, and Eugene Hohlov: PARMS coating technology for UV to IR laser applications, PhotonicsViews, E-Special 1, 2025, published 23 January 2025

Company

I-Photonics UABParko st. 3

Avizieniu, 14180

Lithuania

most read

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy