Laser-based welding in lightweight construction

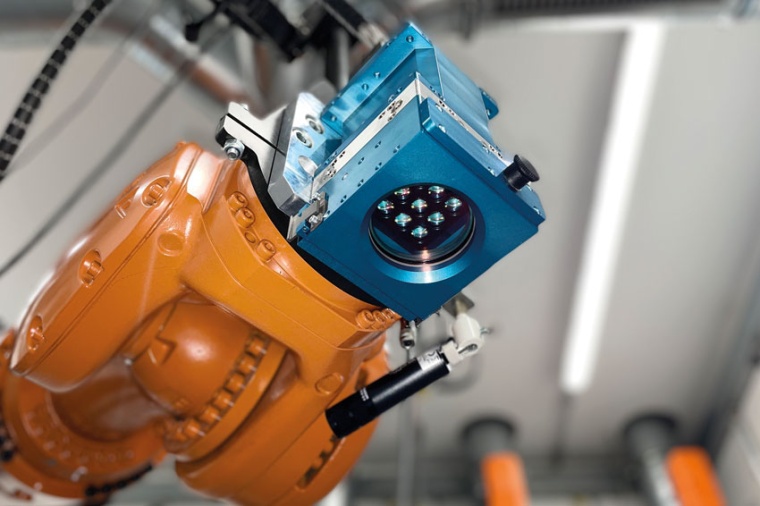

Projects Twin-Weld and MULTISPOT overcome the limitations of fixed bifocal optics and develop a welding head with a matrix of 3 × 3 laser diodes that can be individually controlled.

LMB Automation was engaged in two collaborations with research institutions and industry partners to improve laser welding under certain conditions, to overcome the limitations of fixed bifocal optics, and to implement the process on automotive parts.

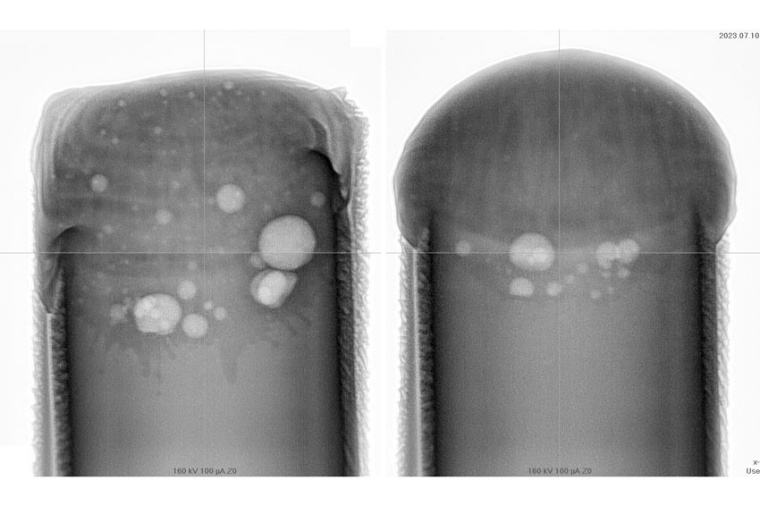

The laser beam tool has become an integral part of modern production, and the requirement for improved efficiency and new potential applications is continuously growing. With new fields of application, component geometries and materials, the conventional optics with limited movement and limited beam shaping options are often no longer able to guarantee a flawless welding result. Such applications include, for example, the joining of thermoplastics and metal as structural components in vehicle construction, and the welding of hairpins in electric motors. For this reason, the LMB laser specialists have developed two new concepts with partners that can be used to positively influence the melt pool through more flexible control and more precise power distribution. With the twin-weld process, better mixing in the melt pool is achieved so that gaps can be bridged more quickly. Multispot allows the intensity distribution within a laser focus to be varied locally and temporally. The performance can then be precisely adapted to the weld geometry and material properties.

Read the interactive issue in the Adobe Cloud, or download the single-article PDF – Laser-based welding in lightweight construction, PhotonicsViews 22 (D1), April 2025, pp. 35–39

most read

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People