New metasurfaces to control lasers

Supercell metasurfaces for multifunctional wide-angle optics and lasing.

The ability to precisely control the various properties of laser light is critical to much of the technology that we use today, from commercial virtual reality (VR) headsets to microscopic imaging for biomedical research. Many of today's laser systems rely on separate, rotating components to control the wavelength, shape and power of a laser beam, making these devices bulky and difficult to maintain. Now, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences have developed a single metasurface that can effectively tune the different properties of laser light, including wavelength, without the need of additional optical components. The metasurface can split light into multiple beams and control their shape and intensity in an independent, precise and power-efficient way.

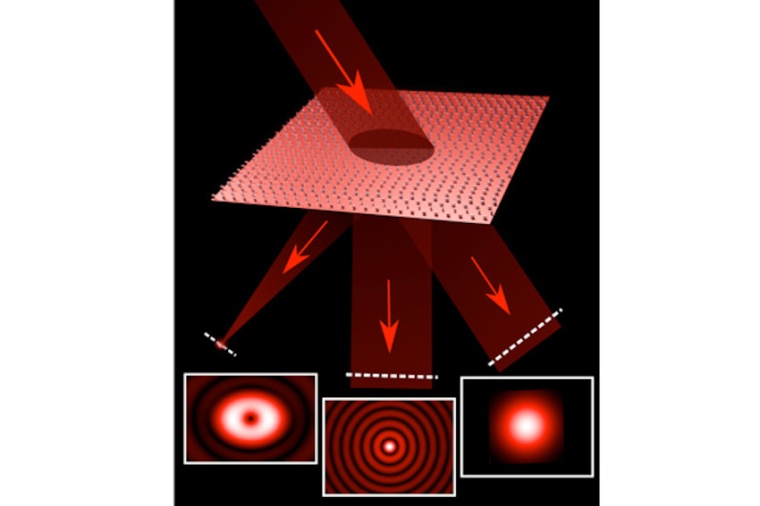

The research opens the door for lightweight and efficient optical systems for a range of applications, from quantum sensing to VR/AR headsets. “Our approach paves the way to new methods to engineer the emission of optical sources and control multiple functions, such as focusing, holograms, polarization, and beam shaping, in parallel in a single metasurface,” said Federico Capasso from SEAS at Harvard University. The tunable laser has just two components – a laser diode and a reflective metasurface. Unlike previous metasurfaces, which relied on a network of individual pillars to control light, this surface uses so-called supercells, groups of pillars which work together to control different aspects of light.

When light from the diode hits the supercells on the metasurface, part of the light is reflected back, creating a laser cavity between the diode and the metasurface. The other part of the light is reflected into a second beam that is independent from the first. “When light hits the metasurface, different colors are deflected in different directions,” said Christina Spägele, a graduate student at SEAS. “We managed to harness this effect and design it so that only the wavelength that we selected has the correct direction to enter back in the diode, enabling the laser to operate only at that specific wavelength.”

To change the wavelength, the researchers simply move the metasurface with respect to the laser diode. “The design is more compact and simpler than existing wavelength-tunable lasers, since it does not require any rotating component,” said Michele Tamagnone, former postdoctoral fellow at SEAS. The researchers also showed that the shape of the laser beam can be fully controlled to project a complex hologram – in this case the complex, century-old Harvard shield. The team also demonstrated the ability to split the incident light into three independent beams, each with different properties – a conventional beam, an optical vortex and a Bessel beam, which looks like a bullseye and is used in many applications including optical tweezing.

“In addition to controlling any type of laser, this ability to generate multiple beams in parallel and directed at arbitrary angles, each implementing a different function, will enable many applications from scientific instrumentation to augmented or virtual reality and holography,” said Capasso. (Source: SEAS)

most read

Otto wins IERA Award 2025

Rockwell's robot is an AMR solution that can transport heavy loads in factories and operate in robot fleets of over 100 units.

HMS Networks takes over Industrial Communications division from Molex

This strategic acquisition includes intellectual property in hardware and software, a product portfolio with network cards and software stacks, as well as customer relationships in the USA and Japan.

First access for external users to the QSolid quantum computer

The prototype of the QSolid quantum computer was successfully integrated into the JUNIQ infrastructure of the Jülich Supercomputing Center.

United Robotics Group restructures

The company focuses on the healthcare industry and innovation.

Teledyne Vision Solutions: Camera manufacturer unifies machine vision portfolio

Teledyne combines the various machine vision technologies, including 1D, 2D and 3D cameras, under the umbrella of "Teledyne Vision Solutions".