Fraunhofer Vision with numerous exhibits at Control 2023

05.04.2023 - The Fraunhofer Vision Business Unit will be exhibiting numerous measuring and inspection systems for camera-based quality assurance in production at Control 2023.

At the Control booth, which is coordinated by the Fraunhofer Vision Business Unit, current new developments from many areas and Fraunhofer institutes will again be presented. Get an overview of the latest developments and innovative solutions in the field of image processing for use in industrial quality assurance.

At this year's Fraunhofer-Vision booth, visitors will find exhibits from the fields of

- Inspection and characterization of surfaces,

- optical 3D measurement technology,

- inline measuring and testing and component identification as well as

- augmented reality

- artificial intelligence/machine learning.

In addition, new developments for inspecting components below the surface or inside the material will also be on display, for example

- with X-ray,

- terahertz,

- ultrasound,

- radar or also

- spectroscopic methods.

Image processing technologies and surface inspection

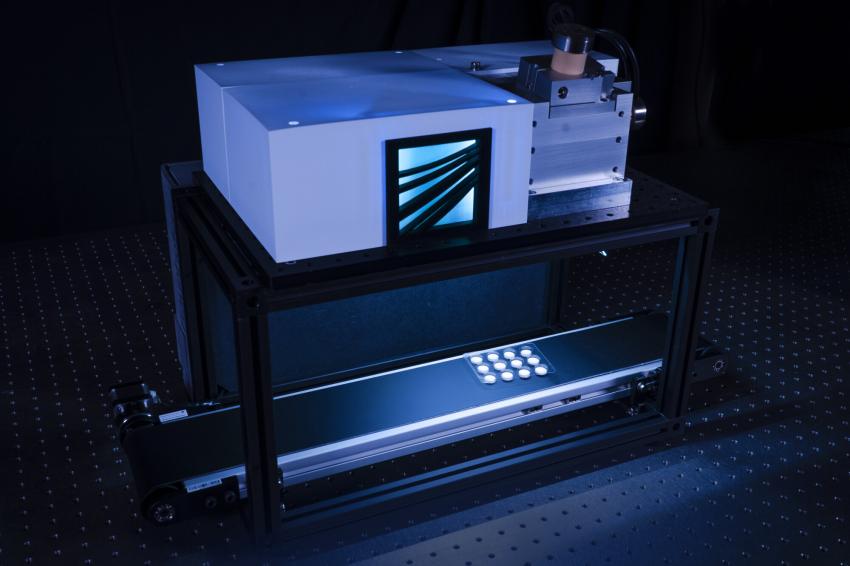

Inline inspection of large surfaces with regard to cleanliness and coating

Fraunhofer IPM is presenting the fluorescence scanner F-Scanner 1D mini at Control. The system detects contaminations on selected areas of large components quantitatively and with high spatial resolution in the production cycle. In addition to cleanliness testing, the device is also suitable for layer thickness measurement, for example of (organic) KTL coatings, or for oil layer measurement in forming processes.

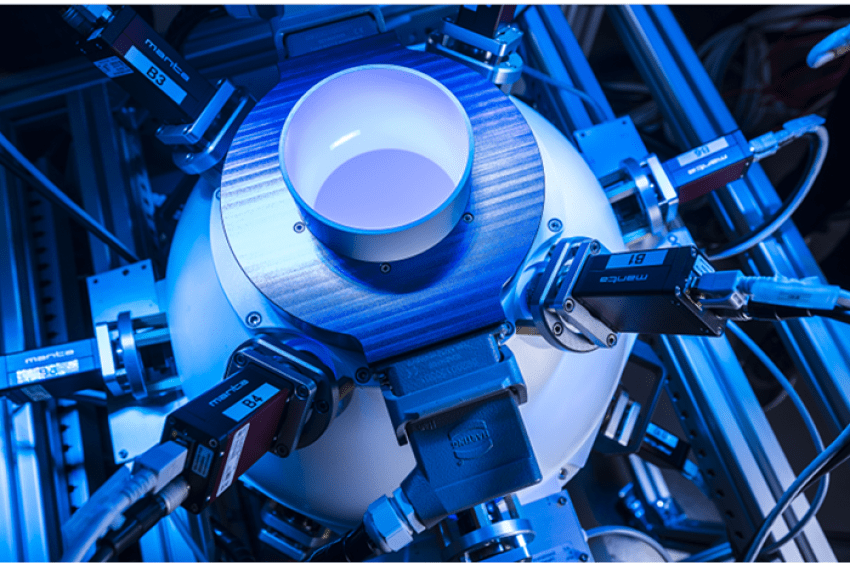

Complete optical inspection of mass-produced components in free fall

The inspection systems of the Inspect 360° series developed at Fraunhofer IPM analyze the geometry and surface condition of components in free fall during production and thus enable, for the first time, a type-independent, complete optical inspection of mass-produced components. At Control 2023, the Inspect 360 HR (high resolution) will be presented, a system for the precise inspection of semi-finished products with regard to the properties geometry and surface defects down to a defect size of 30 μm. The components are conveyed individually into a hollow sphere via a simple feed system and inspected simultaneously from all directions in free fall with the aid of cameras. Metal components from forming, stamping, forging and casting processes or plastic parts as well as hybrid components made of composite materials can be inspected.

Intelligent quality control for reflective surfaces

Whether a painted car or a smartphone display: Before goods leave the production plant, their quality must be checked and ensured. But inspections of reflective surfaces are challenging. Simple photographic processes are not suitable here because of the reflections, and manual quality checks are time-consuming and costly. At Control, Fraunhofer IAIS will be demonstrating a patented system that inspects shiny or diffusely reflective surfaces completely automatically.

High-speed microscope for 100 percent optical quality control

Fraunhofer IPT has developed a high-speed microscope (HSM) that can be used to examine microscopic structures over large areas in a short time as part of an optical 100-percent quality control. The technique can be used for samples ranging from microelectronics to stem cells.

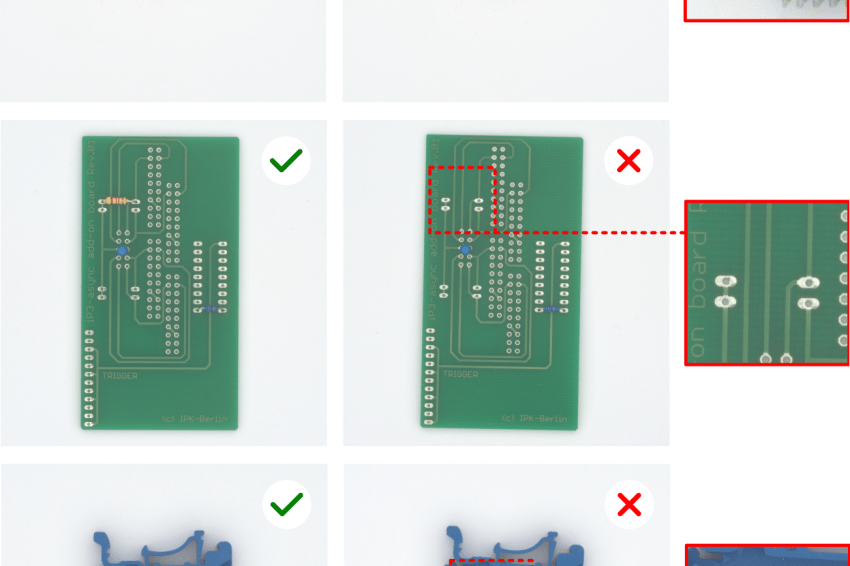

Automating manual inspection - the potential of AI-based image processing

AI-based image processing has the potential to solve even very complex inspection tasks. However, it requires a large amount of labeled training data. Anomaly detection has a lower barrier to entry due to significantly less training data.

a lower barrier to entry. Fraunhofer IPK will interactively demonstrate the opportunities of anomaly detection for optical inspection at Control.

Automating Manual Inspection - Potentials of AI-based Image Processing

AI-based image processing has the potential to solve even very complex inspection tasks. However, it requires a large amount of labeled training data. Anomaly detection has a lower barrier to entry due to significantly less training data.

a lower barrier to entry. Fraunhofer IPK will interactively demonstrate the opportunities of anomaly detection for optical inspection at Control.

Inline surface inspection systems for the inspection of metal parts

Fraunhofer ITWM will present a robotic surface inspection system for the complete inspection of turned and milled metal parts. The system serves as an exemplary application for the objective and complete acquisition and evaluation of the surface, independent of the surface texture. The special feature here is that complex metal objects can be inspected even if not enough defect samples are available for machine learning training.

The solution is based on photo-realistic image simulation with parametric modeling of defects and surface texture. In addition, the positioning of the robot for a complete surface inspection is ensured with the virtual inspection planning software V-POI.

Quality inspection of transparent objects

Fraunhofer IOSB develops visual inspection systems for industrial inspection of transparent materials, among other things. At Control, it will present the "Purity" system, a solution for 100-percent high-speed inspection of transparent objects in a continuous process at a material flow speed of up to 3 meters per second. The inspection is based on unique and standardized features and takes place with a large depth of field. Defects such as stresses or inclusions in the material are reliably detected. Addressed are glass producers, film manufacturers, optical component manufacturers and plastic producers.

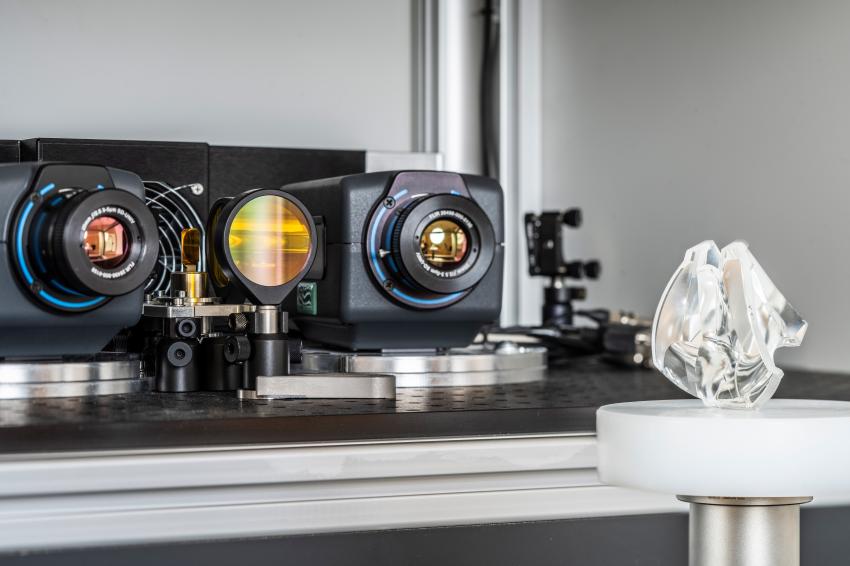

Inspection of reflective surfaces with deflectometry

Fraunhofer IOSB uses deflectometry to inspect flat or curved reflective surfaces. The method is suitable for embossed, polished, painted or glazed surfaces made of plastic, metal, glass and other materials. As a result, information is available on the location, size and type of functional or aesthetic defects and, if required, on the shape and waviness of the surface. Possible applications for the process can be found wherever defect-free surfaces of low roughness are required. A transportable system for inspecting workpieces measuring up to 30 x 10 cm will be presented at the Control booth.

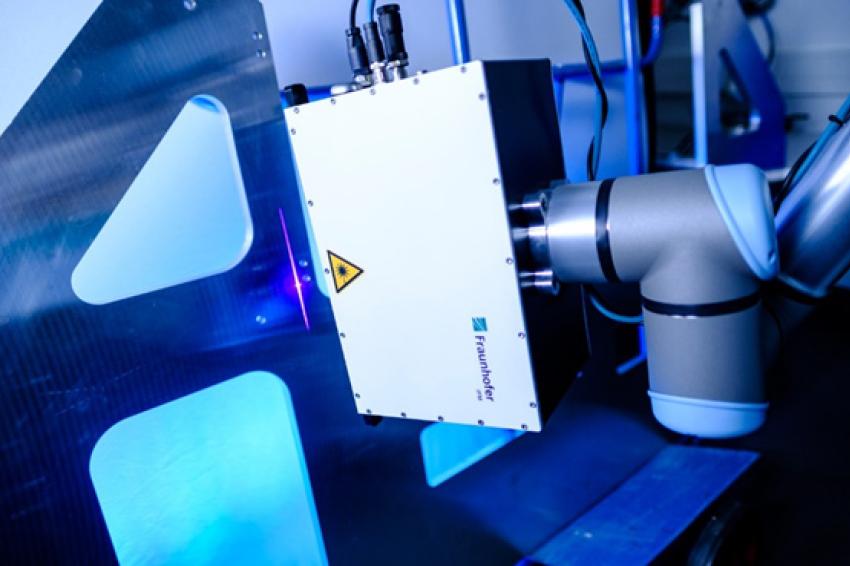

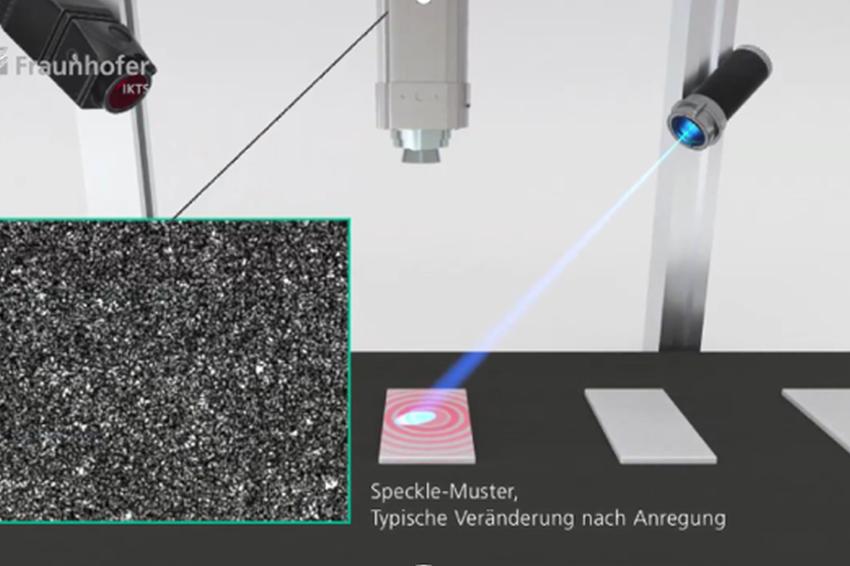

Fast, precise and non-destructive process monitoring with laser speckle photometry

Laser speckle photometry (LSP), developed at Fraunhofer IKTS, is a method for inline monitoring of industrial processes. The robust and cost-efficient system analyzes surface characteristics and draws conclusions about surface defects, porosity or thermal properties for almost all material classes.

AR- and AI-supported assembly of complex product configurations.

Fraunhofer IGD supports users with a combination of augmented reality (AR) and artificial intelligence (AI) to meet production challenges. The solution consists of an AR-supported assembly workstation that guides

guides employees through the assembly sequence while providing component quality control and remote support. Companies thus reduce error rates and costly downtime.

Optical 3D metrology

System for non-contact 3D measurement of transparent objects

Non-contact detection of the surface shape of transparent objects is a major technical challenge. With the Goquality 3D sensor, researchers at Fraunhofer IOF in Jena have developed a sensor that can master this task. The system combines the methods of infrared laser projection and thermography and thus enables non-contact spatial detection of transparent objects as well as components with reflective or light-absorbing surfaces. Applications are especially conceivable in large-scale industrial manufacturing processes such as in the semiconductor or automotive industries.

Scanner for mobile and fully automated 3D measurement of objects.

Virtual 3D models of real objects, so-called "digital twins", offer numerous advantages, be it for digitization or in the quality control of industrial manufacturing. But the more complex an object, the more difficult it is to measure its shape and convert it into a 3D model. With Goscout 3D, Fraunhofer IOF in Jena has now developed a portable sensor that enables flexible 3D acquisition of objects.

Hyperspectral imaging

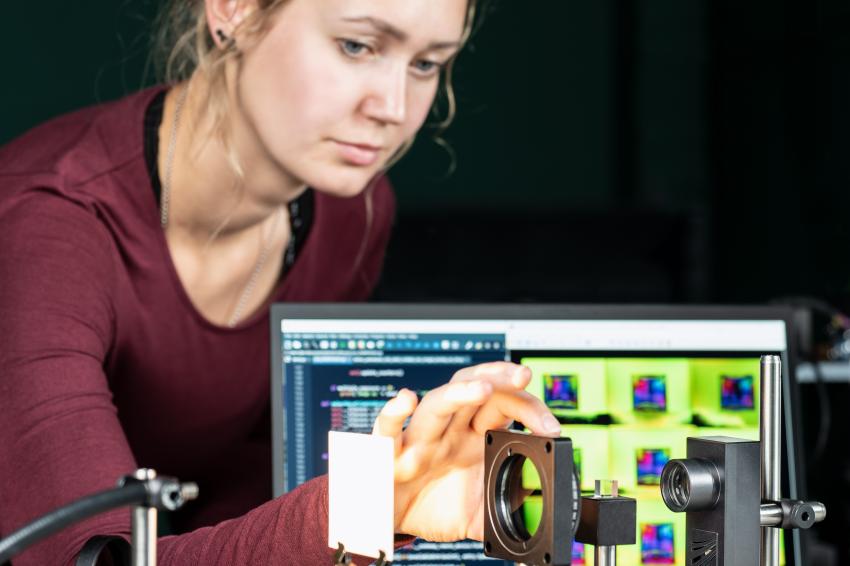

Ultra-compact multimodal camera for capturing image information in nine spectral channels

The use of non-contact inspection systems is steadily increasing in the industrial environment. Multimodal cameras are also increasingly in demand. They should be able to simultaneously capture classical 2D image information, but also 3D, spectral or

polarization information in real time. Against this background, researchers at Fraunhofer IOF in Jena have developed a particularly compact and polarization-sensitive multimodal camera. In the future, this should enable, among other things, effective quality control and predictive maintenance in line with the concept of Industry 4.0. Other potential applications include environmental and agricultural monitoring and biomedicine.

Inline-capable spectroscopic 100-percent inspection for industrial quality assurance and process control

In collaboration with Fraunhofer CAP, Fraunhofer IAF has developed an inline-capable, laser-based infrared spectroscopy measurement system that uses machine vision to specifically detect samples such as blister packs for tablets and verify them within a few milliseconds in a non-contact manner so that contaminated or defectively assembled specimens can be sorted out. The main areas of application for the new measuring system are in the pharmaceutical, chemical and food industries.

Non-destructive testing

Detection of foreign bodies and quality deviations in materials

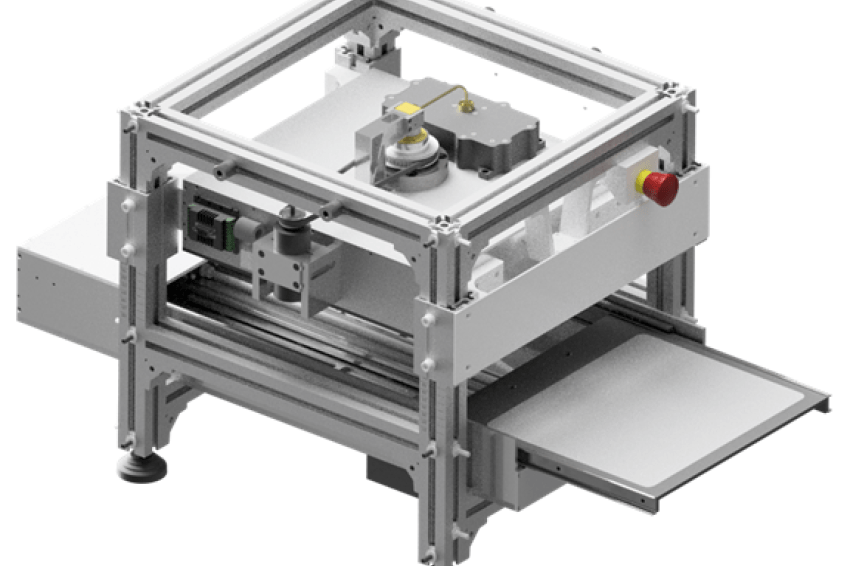

The Sammi 3.0 (Stand Alone Millimeter Wave Imaging) millimeter wave scanner generates three-dimensional images of numerous materials, making their internal structures visible. The system is based on a millimeter wave radar and operates in the 70 GHz to 80 GHz range. A typical application is the inspection of 3D-printed plastic objects, but other products can also be examined, such as packaged food.

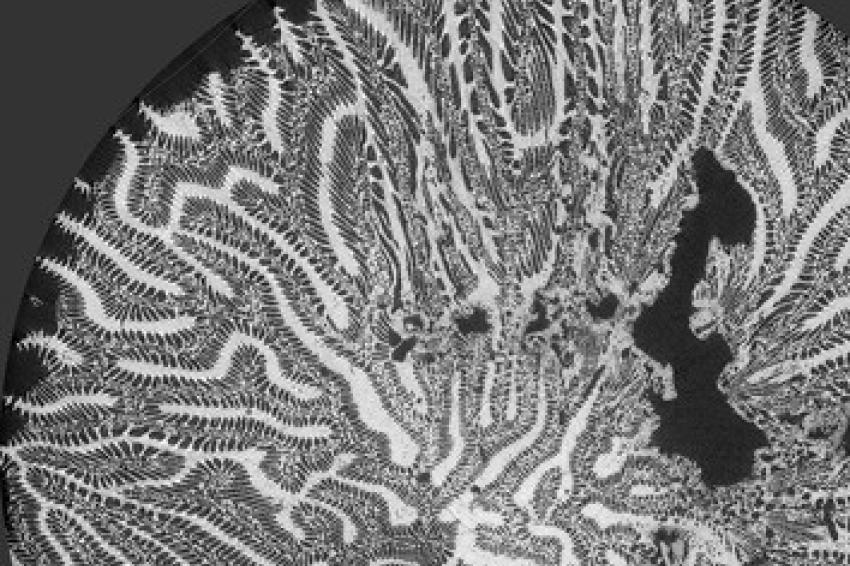

High-resolution X-ray tomography of large objects.

In 2020, the ESRF (European Synchrotron Radiation Facility) in Grenoble, France, launched a synchrotron (the Extremely Brilliant Source EBS), a system that provides the global scientific community with high-energy X-rays of unprecedented brilliance and coherence to study the structure of materials in all their complexity down to the nanometer scale. At Control 2023, Fraunhofer EZRT, as one of the cooperation partners of ESRF, will present Beamline 18, the new technical possibilities opened up for research and development by the availability of high-resolution X-ray images of aircraft or car parts, batteries or composite materials.

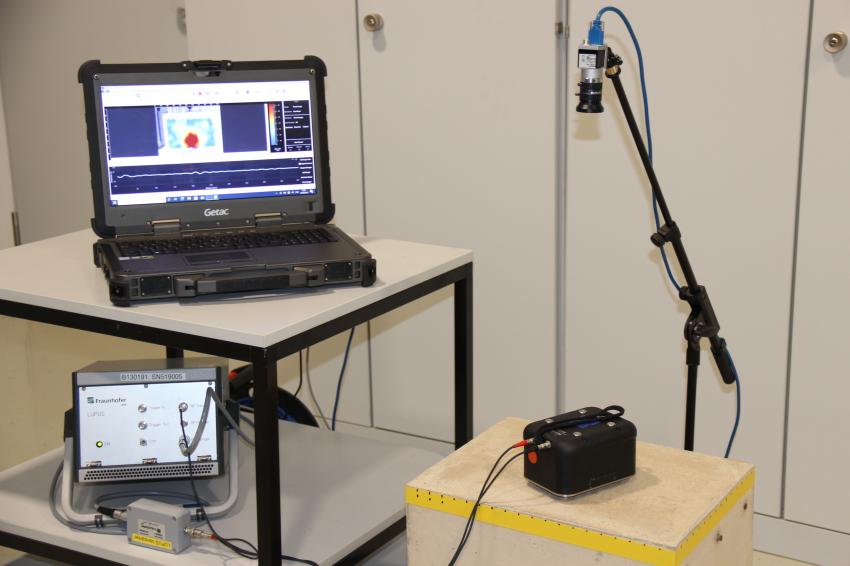

Intelligent assistance system with interactive visualization for laboratory and service tasks

The planned service life of structures can only be achieved if quality-assured designs and the maintenance measures required during the service life are coordinated. Therefore, it is often necessary to record component-specific characteristic values non-invasively with a high accuracy of measured value recording and location. "3D-Smartinspect" from Fraunhofer IZFP is a system for the digitization of near-hand inspection. The system consists of a low-cost webcam, a computer with special software and can optionally be combined with a Hololens.

After a short setup, the system tracks the movement of the inspection head and logs inspection positions and measurement signals. In this way, inspection tasks in the field in particular are facilitated, such as the inspection of safety-relevant industrial components or infrastructure.

At Control 2023, the institute will demonstrate an example of assisted ultrasonic inspection with subsequent reconstruction of the data. The result can be saved in the form of a standardized digital component file in Diconde format (Digital Imaging and Communications for Non-Destructive Evaluation). The assistance system thus makes it possible to provide digital twins with in-situ quality data in many industrial application areas, such as construction, transportation, aerospace and other sectors.

Acoustic monitoring in production

Fraunhofer IDMT presents a method for acoustic quality assurance based on sound analysis and artificial intelligence, which can provide a profitable supplement to optical testing methods when these reach their limits. Possible areas for the use of acoustic methods include the monitoring of welding or machining processes. At the booth at Control 2023, the method will be illustrated using an air field hockey table on which three visually indistinguishable pucks made of different materials can be distinguished only by their sound when they hit the board.

Measuring, simulating, testing with ultrasound

Fraunhofer IKTS develops customer-specific ultrasonic testing systems, components and algorithms, validates ultrasonic methods and offers testing services. At Control, new developments of the PCUS pro-device family, which is optimized for fast automated and, if required, robot-supported testing in metal processing as well as in the areas of railroad and automotive construction, power plant and wind power technology.

Contact

Fraunhofer Geschäftsbereich Vision

Flugplatzstraße 75

90768 Fürth

Germany

+49 911 580 615 800

+49 911 580 615 899