Innovative monochromator optimizes process control

Patented device measures the optoelectronic properties of semiconductor materials over a broad spectral range.

Electronics, power electronics, light-emitting diodes, sensors, photocatalysis and photovoltaics – these technologies are based on semiconductors with band gaps ranging from the near infrared to the deep ultraviolet. New semiconductor materials with interesting optoelectronic properties are constantly being developed. In particular, the spectrally dependent photoelectric characterization of semiconductor materials requires light sources whose photon energy can be continuously varied. Such light sources consist of a lamp, which emits light over a broad spectral range, and a monochromator, which filters out light in narrow spectral ranges. Until now, only diffraction grating monochromators have been used commercially, requiring up to five different diffraction gratings to cover a wide spectral range.

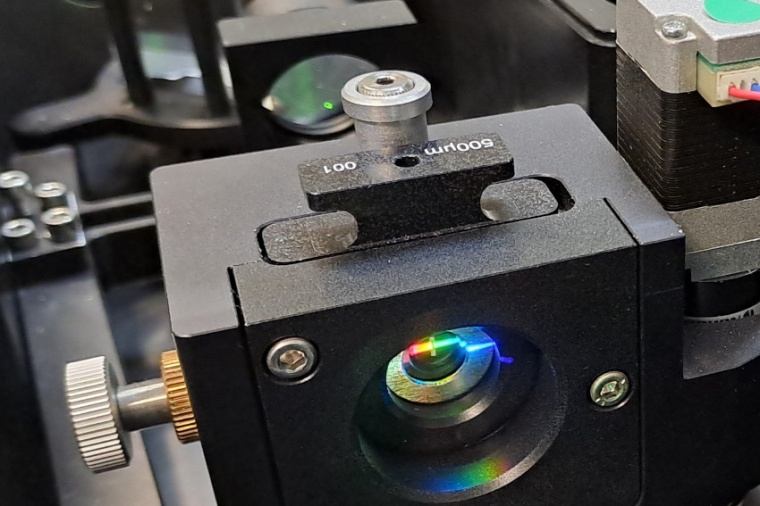

At the HZB in Berlin, a team led by Thomas Dittrich, in collaboration with Hereon research center near Hamburg, has now developed a mirrorless double prism monochromator based on fused silica. Since fused silica is transparent in a spectral range from about 0.4 to over 7.3 eV, light can be spectrally dispersed over this range with just one fused silica prism. A first prototype was realized together with Freiberg Instruments. The novel, now patented, monochromator consists of a fused silica optics with two prisms and some lenses, where in addition to the dispersion-dependent rotation of the prisms, a precise adjustment of the lenses is done via stepper motors. A laser-driven xenon lamp provides high light intensities even in the deep ultraviolet.

The new monochromator makes it possible to determine the optoelectronic and optical properties of semiconductor materials in a single continuous measurement over a very wide spectral range from the near infrared to the deep ultraviolet. An additional advantage: stray light is suppressed very strongly by more than eight orders of magnitude, which makes the monochromator particularly suitable for the photoelectric characterization of defects in semiconductors. Due to its high intensity even in the deep ultraviolet, the monochromator is also excellently suited for the characterization of semiconductor materials with wide or ultrawide band gaps, such as silicon carbide and gallium oxide for high-performance electronics, diamond for IT technologies and gallium nitride for optoelectronics. With the new compact monochromator, for example, it is now possible for the first time to characterize defect states across almost the entire band gap of aluminium nitride in just a few minutes.

The new monochromator improves the characterization of electronic properties, especially of wide and ultrawide bandgap semiconductors. This innovation is therefore not only relevant for the research and development of new materials, but can also be used in process development and industrial process control. In collaboration with Freiberg Instruments, the HZB researchers have already built a prototype. Freiberg Instruments is introducing this compact monochromator into the market now. "There is a lot of interest and demand," says Thomas Dittrich. (Source: HZB)

Link: Nanoscale Solid-Liquid Interfaces (T. Dittrich), Helmholtz-Zentrum Berlin HZB, Berlin, Germany