Improving dimensional awareness

3D vision is increasingly used in conjunction with machine learning in many application areas. The latest COM-HPC modules not only offer these applications significantly higher computing power, but also help with hardware consolidation.

The use of 3D vision is on the rise, with an increase of close to 15% year-on-year. Two factors at play are a decrease in citizens actively working and an increase in citizens requiring health care. Additional robots are therefore required, due to a reduction in the workforce. Robots achieve much higher production efficiency than humans in the manufacturing industry, while robots provide care and promote autonomy/mobility in healthcare.

Bringing the future into focus

However, there is still a lot of development work to be done before robots can perform any heavy work. For example, inspection systems are stationary and immovable. While Vision Guided Robotics (VGR) does offer more mobility, and is experiencing dynamic development, its movement is still rather limited. The main function of immobile robots is to watch things closely. The use of 3D cameras allows them to perform this task more efficiently by identifying objects from three axis and measuring lengths. A thirst for increased flexibility in discrete manufacturing is driving industry growth in this area, which mainly comes from the importance it has gained as a result of the Industry 4.0 trend of moving closer to batch size 1.

Feeding and output systems in discrete manufacturing are mainly VGR and automated guided vehicles (AGV), with a projected growth rate of 14.1% per year until 2027. Permanently installed conveyor systems will be minimized, or eliminated, due to the implementation of AGVs for moving and transporting products. Due to their mobility, they do no block areas like conveyor systems. They move along pre-programmed routes that optimize warehousing, transport, and other tasks. When used with mobile pick & place robots, integration with VGR systems is the result.

Modularity plays a crucial role

Advanced mobile robotic systems may require additional subsystems. A good case to highlight is a robot that was constructed with four legs and featured a total of three Computer-on-Modules. Each module performed a specific task – locational awareness, motion control and task fulfilment. This example demonstrates the advantageous use of Computer-on-Modules, which can be easily scaled for each specific task. Controls could also be combined within a single system for communication with the drives’ actuators/frequency inverters in real-time using a two-wire Ethernet, although modules with significantly more power on a time-proven platform strategy would be required. It should be noted that all in all 10 processor cores on 3 modules, which have not been introduced on the market for ultra low-power mobile embedded systems, were used in this example to deliver the required computing power and ensure real time operation.

Supercharging multi-purpose with higher core counts

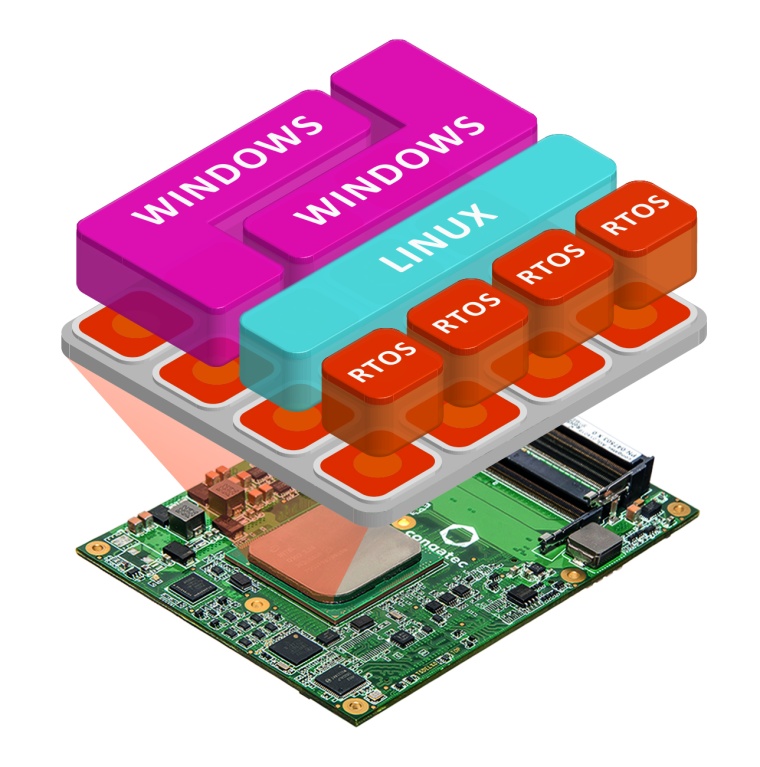

COM-HPC modules that eclipse current COM Express module performance with substantially more interfaces, bandwidth, memory and cores are starting to become available after the PICMG standardization committee ratified the COM-HPC Computer-on-Module specification. This is true for COM-HPC client modules, but affects the server category even more, as future solderable entry class COM-HPC server modules will be more durable and scalable, allowing for consolidation of decentralized real-time control systems in multi-purpose embedded edge computer solutions. Hypervisors from manufacturers like Real-Time Systems would be required for virtual machines capable of real-time operation. Real-time hypervisor solutions are required for uninterrupted, deterministic real-time control, regardless of rebooting on the same HMI processor of the production cell or the evaluation and conversion or data or processing of tasks in parallel by the integrated loT gateway.

A growing hunger for higher performance

Processor hungry 3D imaging needs the power of COM-HPC. Just consider the creation of point clouds acquired by time-of-flight (ToF) technology, which outputs 32 bits of spatial coordinates for each pixel. A resolution of 640 x 480 pixels at 30 frames per second (fps) therefore produces 35 MB of 3D data per second. On top of this the color information of a classic 2D camera, with generally 4 times higher resolutions has to be processed as well. At 1.2 mega pixels (1280 x 1024 pixels) and 8-bit color depth per channel, we are talking about an additional 112.5 MByte per second. These result in up to around 150 megabytes of data that is to be processed per second, not to mention the excessive processing power required for two cameras operating in stereo. Since the amount of data and CPU / GPGPU computing power are extremely demanding, the brand new generation of COM-HPC modules utilizing 12th generation Intel Core processor technology (Alder Lake) are preferred. Their standout attributes include providing PCIe Gen 5 with four times as much bandwidth between processors and cameras, as well as discrete GPUs, compared to PCIe Gen3. Native support of MIPI-CSI cameras also provides two main benefits – reduction of processing requirements and the need for investments in camera technology. Customizable connections of 1GbE and 2x 2.5GbE (with TSN) Ethernet options to dual 10GbE, which are coming from congatec’s COM-HPC starter set, are compatible with the modules. Interfacing with smaller devices, such as actuators and sensors, is therefore possible if two-wire Ethernet is used.

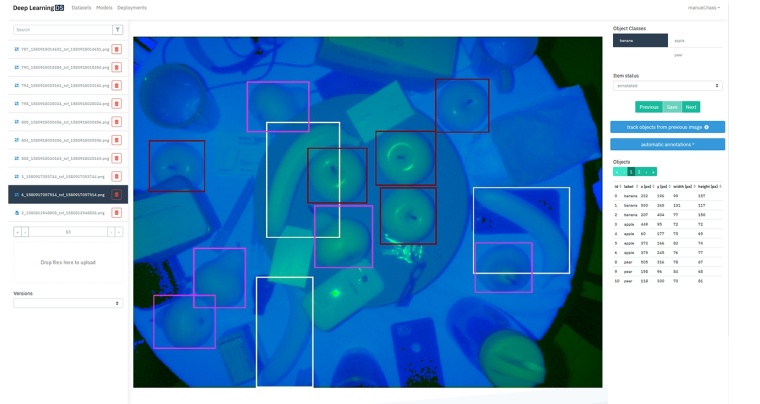

Keeping AI firmly in the mix

Congatec bietet darüber hinaus für IIoT- und Industrie 4.0-vernetzten Embedded-Systeme mit MIPI-CSI Kameras zusätzlichen Plug-and-Play-Komfort für KI-Applikationen. So unterstützen die Module eine KI- und Inferenz-Beschleunigung auf der CPU mittels Intel DL Boost basierter Vektor-Neural-Network-Instruktionen (VNNI) und auf der GPU mittels 8-Bit-Integer-Instruktionen (Int8). Auch die Kompatibilität mit dem Intel Open Vino-Ökosystem für KI sollte erwähnt werden. Das Autonomous System Lab der Intel Labs China hat bereits eine auf COM Express basierende Plattform für Schulungszwecke vorgestellt. Mit dieser HERO-Plattform können Ingenieure nun das OpenVINO-Ökosystem evaluieren – von den Softwarebibliotheken bis hin zur Adaptive Human-Robot Interaction (AHRI) oder Simultaneous Localization & Navigation (SLAM). Zudem gibt es auch schon ein Intel zertifiziertes „ready for Production“ Kit für die Workload-Konsolidierung.

Evaluation by the ATX carrier board conga-HPC/EVAL-Client

Smart vision robotics and autonomous logistics vehicles can be also evaluated by the ATX carrier board conga-HPC/EVAL-Client. It comes with two massively performant PCIe Gen4 x16 interfaces and many LAN options for data bandwidth, transmission, and connectors. Mezzanine cards allow the carrier to run up to two 25GbE interfaces. The conga-HPC/cTLU Computer-on-Module is the main component of the starter kit presented for COM-HPC Client designs. Three processor configurations are available, with three cooling solutions to go with the configurable 12 to 28 W TPD range of the 11th generation Intel® Core™ processors.

Authors

Jürgen Jungbauer, Senior Product Line Manager

Zeljko Loncaric, Marketing Engineer

Company

congatec AGAuwiesenstr. 5

94469 Deggendorf

Germany

most read

A New Approach to Fan Inspection

Reliable Quality Control during the Production of Fans for Diesel Engines

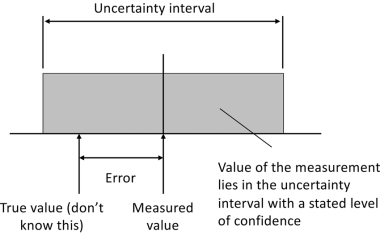

Measurement uncertainty in manufacturing: Understanding the basics

Why precise measurement results alone are not enough

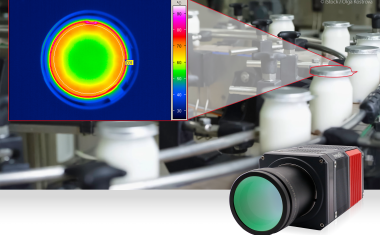

MWIR system camera for continuous industrial operation

Entry into infrared imaging

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People