Robot Vision Guidance for Automated Assembly Applications

05.05.2020 -

Today’s industrial robots require a pre-programmed motion plan. This is because without machine vision, parts must be exactly positioned in order for the robot to locate them in space. In many assembly applications, however, part tolerance stackups lead to levels of variation that make effective automated assembly with robots difficult to achieve.

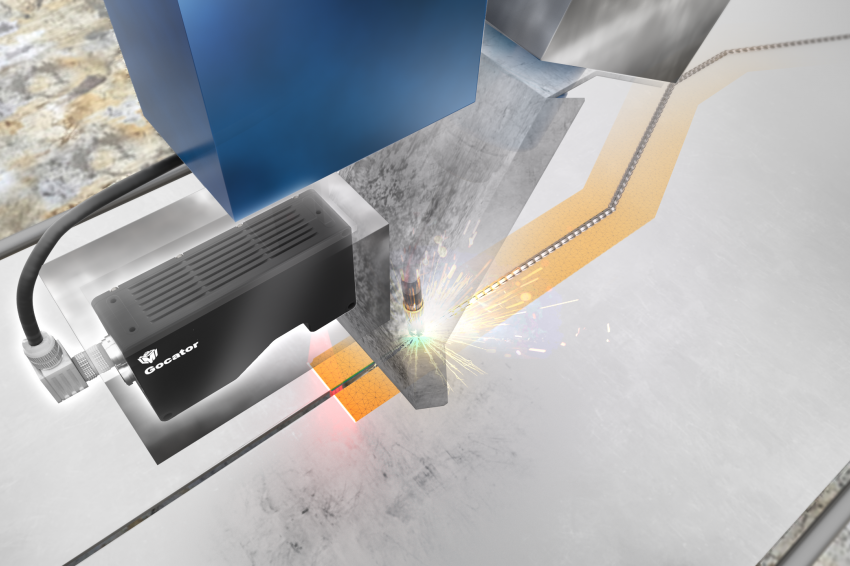

Adding 3D Vision to Arc Welding Robots

In automated arc welding applications, a robot is precision-programmed to follow a weld path where torch positions and torch angles are specified according to narrow mechanical tolerances on the workpiece setup. To achieve a high-quality weld, any mechanical deviations must be prevented on workpieces and fixtures, and all seam locations must be 100 % correct. The main challenge in this approach has been meeting the tight tolerances required to produce high-quality welds over long periods of time.

The Smart 3D Solution

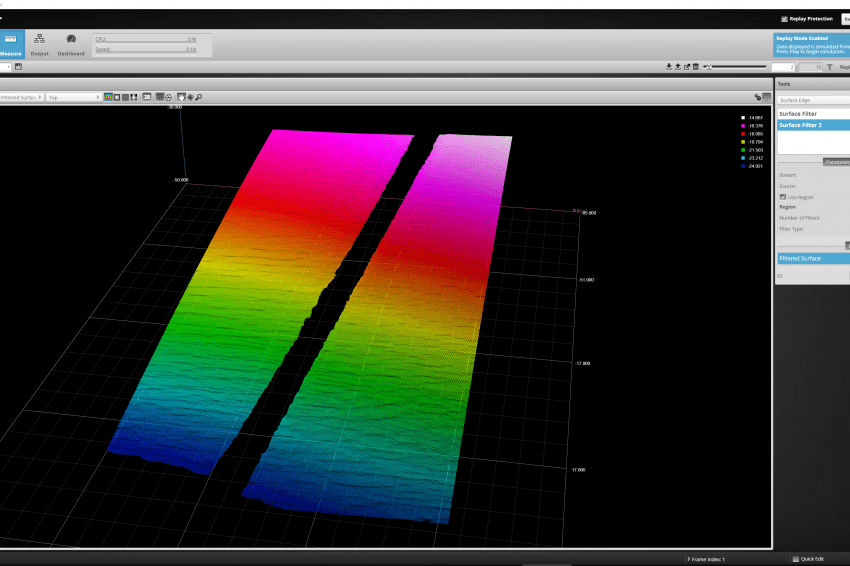

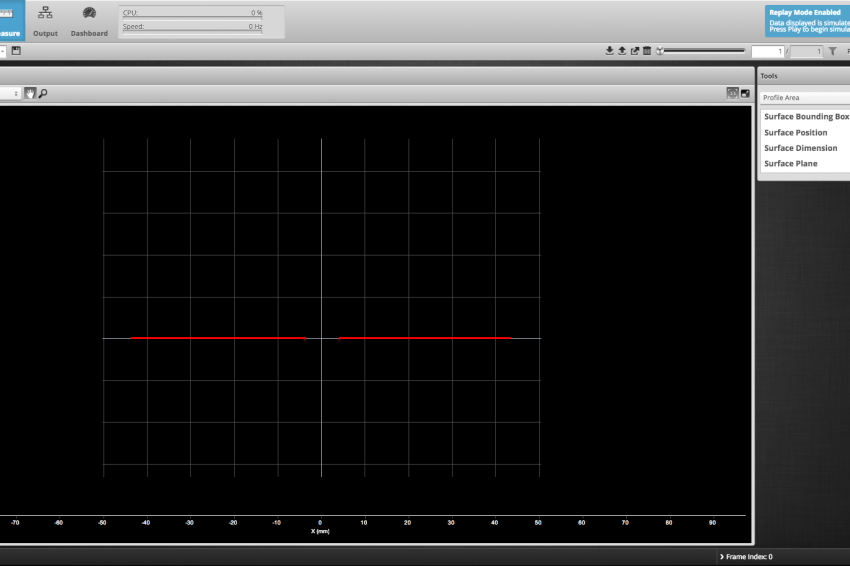

LMI´s Gocator uses non-contact laser line profiling technology, within a compact design that allows it to fit into small work areas. The sensor’s visible laser light makes it easy to precisely position the robot for initial system setup. The sensor head is easily integrated with a robot controller over Ethernet for maximum flexibility in order to provide vision guidance to the robot. This simplifies part fixturing issues and improves weld positioning for improved joint quality.

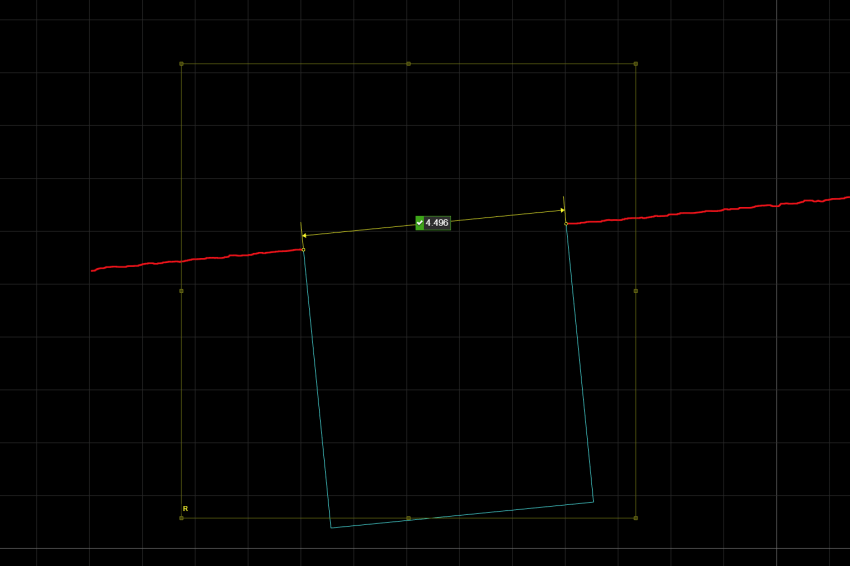

In addition, Gocator sensors have an embedded processor and onboard software to transform signals from the sensor head into calibrated digital data and determine the actual position of the weld seam. When it has located the seam position, the position is communicated directly to the robot controller. The robot then corrects the movement according to the actual position and executes a perfect weld every time. With this closed loop system capability, welding quality is substantially increased and costs for rework, trimming, and scrap are minimized.

This vision guided robotic system can handle seams such as fillets, butts, and edge/ overlap joints. The robot is programmed with parameters such as joint type and plate thickness. During the search process, points along the joint are defined in 2 or 3 dimensions. Searches are accomplished without the arc being activated. Distance measurement can also be given for real-time Z height positioning.

Welding Environment

The arc welding environment is extremely hostile. Weld splatter, smoke, and dirt are generated by the weld operation. To protect the sensor during the actual weld, a pneumatic shutter over the sensor head provides mechanical protection. Standard cooling and air purge systems further enhance its use in harsh environments for optimum functionality and reliability. Furthermore, an IP67-rated aluminum housing ensures that the sensors are protected from moisture, dirt, and vibration.

Smart 3D in Action: Welding Car Door Hinges

Eight laser guidance systems are used to accurately locate the position of eight seam paths, which guide the spot-welding process in robotic arc welding of door hinges onto car bodies.

Driven by Gocator 3D sensors, these systems are able to guide the robot to properly position the door hinge within search times of under 1 second. With 3D location data, the robot can position the welding tip at the exact spot with a search accuracy of ±0.1 mm. Quality welds are produced on every assembly, even when components and fixtures are not perfectly positioned.

Conclusion

Automating assembly operations such as arc welding requires the ability to determine the accurate locations of one or more features and feeding this information to the robot controller to correct the robot path to complete a quality assembly. The smart sensors provide a solution to this challenge by using built-in tools and communication protocols to offer vision guidance in these robotic assembly applications.

Case Study: Automated Rivet Hole Inspection in Aircraft Section Assembly

The Application

Aircraft production presents various technical challenges, such as large product dimensions, complex joining processes, and the need for proper organization of assembly tasks. Overcoming such challenges while enforcing tight tolerances and managing small batch sizes is often difficult to achieve with a high degree of cost efficiency.

The Challenge

In the assembly of the aft section of the aircraft, the pressure bulkhead is mounted to the section barrel. Two operators must work collaboratively in uncomfortable, non-ergonomic positions, while having to maintain exacting assembly quality standards.

The Solution

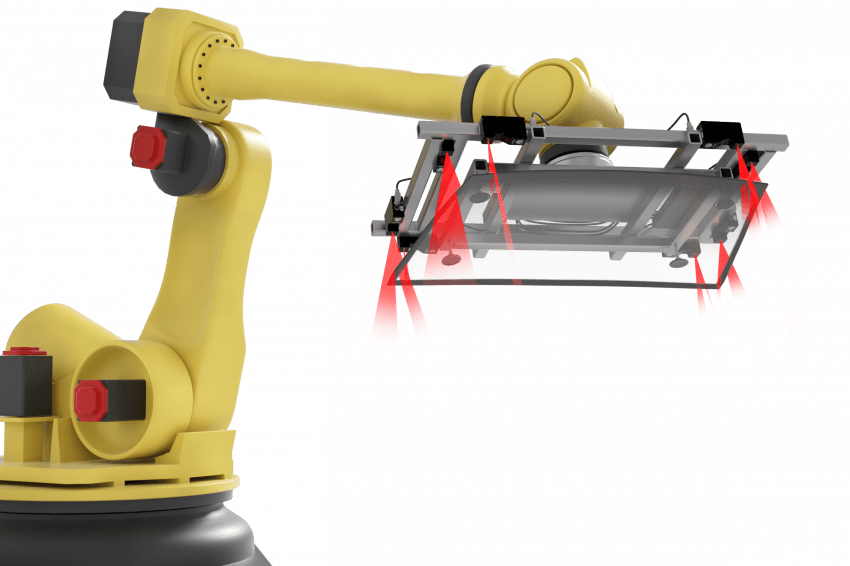

ZeMA gGmbH devised a semi-automated approach to optimize aircraft section assembly. This was achieved through an innovative riveting process for solid rivets, using Human-Robot-Collaboration in combination with an intuitive Human-Machine-Interaction operational paradigm. ZeMA’s solution leverages collaboration between humans and robots in order to complete the task more efficiently. First, the solution involves placing a robot inside the section barrel. The robot’s workspace is then expanded by mounting it on top of a lifting unit, which enables it to position the anvil properly in front of the bulkhead. At the same time, a human performs the more complex tasks of inserting the solid rivets and operating the riveting hammer from outside the sectional barrel.

To create the robotic system used in this application, a Gocator 3D laser line profile sensor is mounted and calibrated to the robot flange using built-in hand eye calibration. The sensor is then able to provide 3D coordinates of every measured point. With onboard data processing and built-in measurement tools, the sensor detects the holes in the frame or shell of the aircraft, enabling the riveting process to be completed with maximum accuracy and efficiency.

Tasks in the riveting process are divided between human and robot. The human detects the designated hole, inserts the rivets, positions the riveting hammer and starts the collaborative process by activating the hammer. In parallel, after ascertaining the position of the holes, the robot positions the anvil and bucks it against the rivet during execution of the process.

“We picked the LMI sensor because it can be integrated very quickly and flexibly into our robot applications and enables onboard data processing, which is a great advantage for the rapid implementation of research ideas and feasibility studies. In addition to onboard data processing, access to the sensors raw data is an important factor for us - and this is also made possible by LMI. All in all, we have the perfect scope for research and industrial applications with Gocator sensors”, said Tobias Masiak, Research Assistant (Robotic & Human-Machine-Interaction) at ZeMA gGmbH.

The Result

With the introduction of a Gocator laser triangulation sensor the distance between rivet and anvil no longer depends on human judgement, but on the measurement precision of the sensor, the robot positioning, and the calibration of the tool (e. g., anvil, additional production equipment). As a result of automating this complex process, assembly errors and deviations are greatly reduced.

Next Steps

Refinement of this solution is ongoing, including long-term stress testing of the developed process tools and the integrated robot system. Furthermore, the test series includes quality inspection using data fusion from Gocator, camera and force-torque data, as well as information gathered from operator experience. Combining the data with Artificial Intelligence algorithms will be introduced in future iterations.

Zitat: Gocator sensors have an embedded processor and onboard software to transform signals from the sensor head into calibrated digital data and determine the actual position of the weld seam.

Contact

LMI Technologies Inc.

9200 Glenlyon Parkway

V5J 5J8 Burnaby

BC, Canada

+1 604 636 1011

+1 604 516 8368