Real 3D From a Single Source

18.04.2023

- Powerful 3D Package for All 3D Sensors and Numerous Industrial Applications.

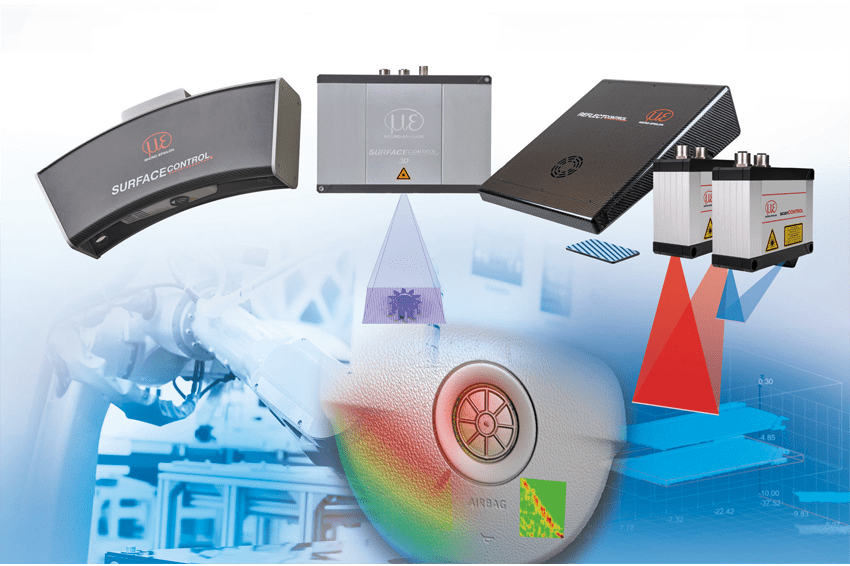

A new, high-performance 3D sensor generation features software which provides real 3D evaluations and is compatible with a complete range of sensors.

To achieve highly accurate 3D measurements, a perfect match of hardware and software is required. Sensor specialist Micro-Epsilon has taken this into account in the development of the new 3D sensor generation and therefore not only relies on powerful hardware, but also supplies the perfectly matched 3D Inspect software to go with it. This means that all of the manufacturer’s 3D sensors can be operated with uniform software. It is is compatible with surface control sensors for geometry, shape, and surface inspections of matt objects, reflect control for measurement and inspection of glossy surfaces, and 3D laser scanners for precise inline 3D measurements. The 3D Inspect software enables real 3D evaluations and not just 2.5D as with conventional software. This means that each x-y coordinate has several z-coordinates available. In addition, sensors and software come from a single source, which means that only one contact person is needed to solve complex measurement tasks.

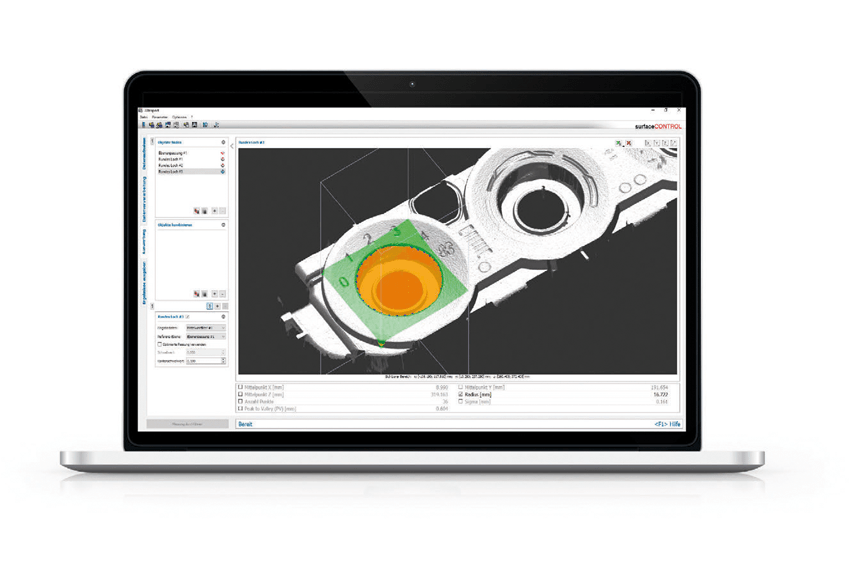

Powerful Software for 3D Point Clouds

3D Inspect is designed for ease of use and offers intuitive operation. The software enables the parameter setting of the sensors, but also the acquisition of the measurement data. The tool palette is versatile and ranges from the alignment of point clouds and the selection of relevant objects, to filters for smoothing and optimizing the point cloud. Calculation programs for distance, height, angle and radius are also already integrated. The determined data can be easily output to the PLC but can also be further processed as desired. In addition to the standard version, the “Automation” function extension supports automated production processes. Video tutorials easily explain the software application and its features. Another benefit: the software is constantly being developed, so is always up to date and every new release offers further useful functions. A comprehensive SDK is available for third-party and custom image processing solutions. This is based on the industry standards GigE Vision and GenICam including numerous function blocks. A C/ C++/ C# library with numerous sample programs and documentation supports software development.

Extensive Software Functions at a Glance

The measurement programs can be divided into three groups. The „Data processing“ to which the point cloud selection, filtering, transformation, and alignment programs belong. Here, among other things, corrections of the position, point selection, alignment based on cuboids, planes, lines, or points are possible. But also average, median, low-pass, high-pass and erosion filters are included.

The “Objects” group contains programs for fitting geometrical objects. Here, for example, centers of gravity or extreme points in the 3D point cloud can be calculated. Fitting of objects such as spheres or cylinders into the point cloud is also possible for further evaluation.

Under “Combine objects” you will find programs that relate previously found objects to each other. This process is based on various calculations such as distance, angle, or center point between two objects.

In “Outputs and Results” the measurement results can be mathematically combined and calculated, and detailed options for signal output are available. Available output formats are UDP, TCP, Modbus, where 3D Inspect acts as the server. With additional modules, control and measured value output are also possible via Profinet and Ethernet/IP.

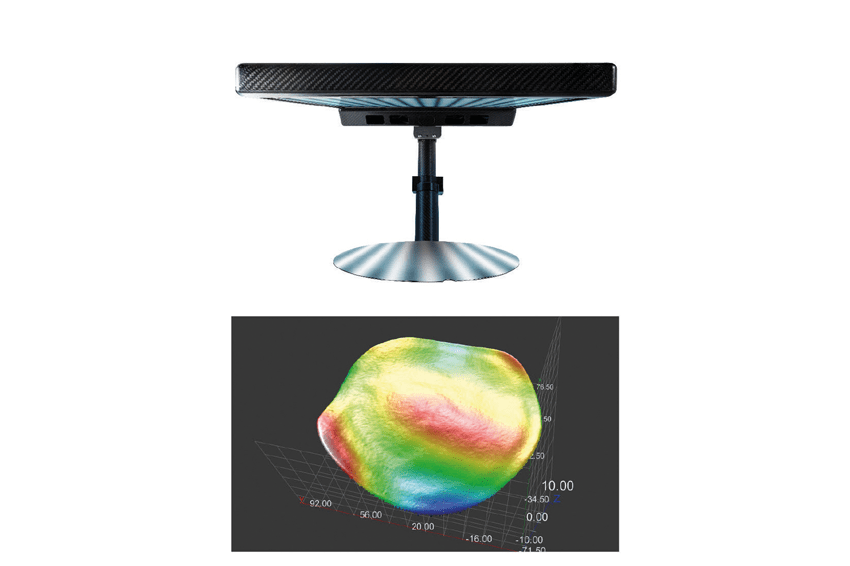

3D Measurement of Diffusely Reflecting Surfaces

The comprehensive 3D software package from Micro-Epsilon is also compatible with the surface control sensors. They are used for fast 3D measurements and inspection of diffusely reflecting surfaces such as metals, plastics, or ceramics. The sensor uses fringe light projection, which can be used to detect diffusely reflecting objects, and calculates a highly accurate 3D point cloud from the acquired data. Based on the point cloud, it is possible to detect geometries and the smallest of defects. Even the finest structures on components and deviations in shape become visible. Sensors with different measurement areas and performance data are available. Since the sensor is extremely slim, it can also be integrated into restricted installation spaces. The special feature of these systems is the combination of automatic surface inspection, highest precision from 0.4 µm, as well as fast and extremely reliable detection of a wide variety of object and surface geometries.

3D Measurement of Shiny Surfaces

The reflect control sensor is designed for 3D measurements on shiny and glossy surfaces. The sensor is suitable for stationary use in micrometer-accurate measurements when monitoring the production line, or for inline inspection on a robot. A fringe pattern is generated on the sensor display, which is mirrored across the surface of the target into the sensor‘s cameras. Deviations on the surface cause distortions of this striped pattern, which are evaluated by the software.

3D Laser Scanners for Inline Quality Inspection

Scan control laser scanners are among the most powerful profile sensors worldwide in terms of their accuracy and measuring rate. In order to generate 3D scans the sensors must move. Either a robot or traversing system moves the scanners over the measuring object, or the measuring objects are guided past the scanner on a conveyor belt. Micro-Epsilon‘s laser scanners offer a unique combination of high dynamism, precision and compactness. The sensor specialist offers a comprehensive portfolio with numerous measuring ranges, Red and Blue Laser technologies and extensive accessories. The scanners are equally convincing for system integrators and for series use in the production line. They can be optimally integrated into image processing software packages via the Ethernet/GigE vision interface.

Conclusion

The special feature of Micro-Epsilon‘s innovative 3D complete package is 3D Inspect, a powerful and at the same time very easy-to-use 3D software that is compatible with the entire range of 3D sensors. This allows numerous 3D measurement tasks to be solved efficiently and with measuring systems from a single source. The sensors are flexible and provide real 3D evaluations for diffuse-reflective, glossy and many other surface types. Measured values are output via UDP, TCP, Modbus, Ethernet/IP, as well as Profinet. For evaluation, the manufacturer offers in-house test measurements as well as rental equipment.

Author

Tanja Schwarz, Marketing

Contact

Micro-Epsilon Messtechnik GmbH & Co. KG

Königbacher Strasse 15

94496 Ortenburg

Germany

+49 8542 168 0

+49 8542 168 90