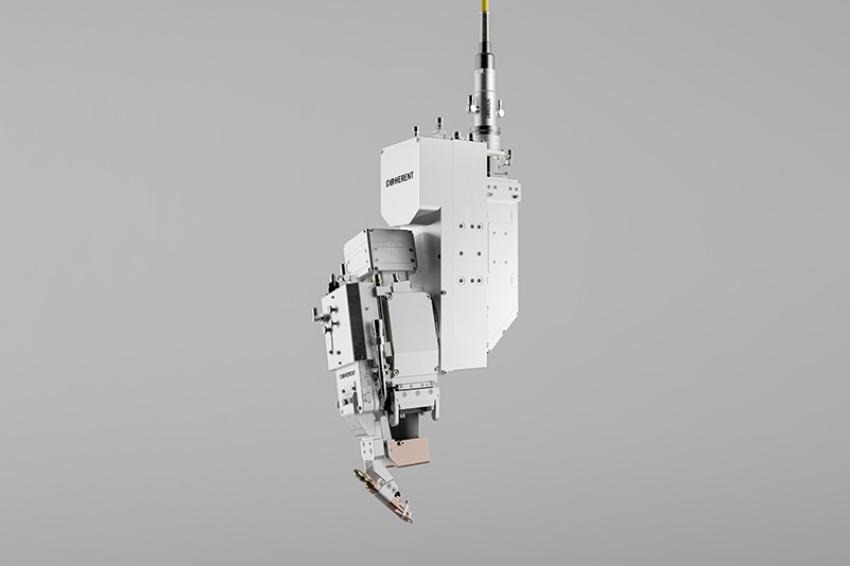

A laser welding with head seam-tracking technology

05.06.2023 - Coherent introduces Hightactile, a laser processing head with a patent-pending seam-tracking technology that is easily configurable to perform automated fillet welding and brazing.

The growing demand for electric vehicles (EVs) is expanding applications for lasers in automotive manufacturing, spurring innovations in process automation and improvements in laser usability. “Hightactile is the culmination of twenty years of experience designing seam-tracking systems for welding and brazing, making it a truly unique product on the market,” said Dr Karlheinz Gulden, senior vice president, laser components and subsystems business unit.

“Our laser processing heads have had great success in automotive manufacturing applications. Now, with the rapidly growing demand for electric vehicles, we are addressing a broad range of new opportunities in critical applications, such as fillet welds that enable battery trays to be stronger and stiffer while at the same time reducing weight,” Gulden continues.

Thanks to its embedded sensors a lot of functional aspect of the welding head are streamlined. The sensors improve process learning and enable faster laser processing. The head can be configured to maximize performance for specific applications such as brazing steel or welding aluminum and steel. Those processes are typically found in body-in-white applications such as trunk lid and roof top brazing. Hightactile can be used with a wide range of lasers, wire feeders, and process monitoring systems.

Coherent will exhibit at Laser World of Photonics, in Munich, Germany, June 27 – 30, Booth B3.321.