For Highest Surface Grade

About 60 surface parameters, with the smallest tolerances, determine the geometry, and thus the lifetime, of drills, milling cutters and thread-cutting tools. Quality assurance depends in a crucial way on the full form measurement of the tool in a high vertical resolution. The use of InfiniteFocus, an optical 3D measuring system, guarantees a high grade cutting edge geometry.

That it’s the cutting edge that makes the money is an adage well known to manufacturers as well as users of drills, milling and thread-cutting tools. Manufacturers of cutting and shaft tools have to meet two decisive requirements. First, they have to guarantee their customers a long lifetime combined with excellent machining results of their tools. Then there is considerable pressure to guarantee repeatable quality at the highest possible process reliability and at low production cost. Production faces the strict requirement of machining a given geometry with steady precision whereas quality assurance needs to make sure that the machined tool shows the right geometry before, during and after the manufacturing process. The finished work piece has to correspond to the pertinent CAD data set. In increasing numbers, this applies to extremely small parts with very narrow tolerances, and thus said requirements can only be met by high resolution surface measurement processes.

Any user of drills and milling tools is well aware about the relevance of a timely change of tools. If a shaft or some other cutting tool, as for example a cutting insert, is replaced too late, the surface quality of the material machined will suffer.

Alicona, a leading supplier of optical 3D measurement and inspection systems, offers with InfiniteFocus a measurement solution that serves both, manufacturers as well as users of cutting and shaft tools. The 3D measurement device is used for full form and roughness measurement as well as wear analysis in the lab and in production. Both parties benefit from the technology of Focus-Variation as it enables the optimization of quality assurance and process reliability.

Optical Measuring System Assuring Geometry

InfiniteFocus is a high resolution optical 3D measurement device for the measurement of critical parameters such as radii and angles of a cutting edge.

With a correct geometry, manufacturer guarantee pertaining lifetimes and machining results of their drills and milling tools. Even when measuring a complex form like those of threads, this measuring system will achieve a vertical resolution of down to 10 nm. The particular advantage of InfiniteFocus is that one single system will cover all functions of both a conventional surface measuring device and of a coordinate measuring machine. Instead of employing several systems the user measures with only one system both – roughness and form of his tools. The high resolution is also present at large scan heights, rendering this 3D measuring device ideal not only for the measuring of miniaturized components, like micro tools, but also of larger components. Even with topographies showing flanks of more than 80˚ will the high vertical resolution be achieved, thus making possible the measuring of sharp edges. Also, ground and mirror-finished surfaces, or a combination of matt, glossy and mirror topographies will be measured in the high resolution.

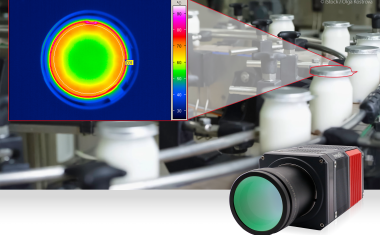

Users of shaft tools employ InfiniteFocus for wear control, amongst others. By defining the ideal point in time during production for a tool change they prevent dull, worn-out edges that would result in faulty machining and waste. Knowing after how many revolutions a drill or a milling tool needs to be replaced will be preceded by comparative examinations of the cutting edge. InfiniteFocus measures tool geometry before and after its use in manufacture. In doing this, the measuring system registers both 3D sets of data and automatically calculates a model of difference, independently of manual adjustment. The worn material is calculated automatically and, in addition, visualized in color. By numerically verifying the material removed after a certain time, it will be calculated exactly at what time and at what degree of wear the tool needs to be changed to achieve constant machining results.

InfiniteFocus measures the radii of cutting tools from 2μm upwards and to minimum angles of 20˚. These data make Focus-Variation a technology much sought-after, as no other process, be it optical or tactile, will offer measurements at this high vertical resolution of down to 10 nm with the given features. High resolution numerical verification of form, spatial orientation and surface roughness of cutting tools guarantees meeting ever decreasing tolerances for position, shape, spatial orientation and diameter. Customarily, at least two systems are required to measure these components in a complete and reliable way. With InfiniteFocus, however, the user has a system at his disposal with which he may measure roughness and form, i.e. length, diameter, angles, inclinations, roundness etc., with one and the same system.

Shaft Tools Measured 360˚

There are about 60 surface parameters defining the geometry of shaft tools, and with them their lifetimes and machining results. Meaningful measurement demands the full form measurement in a three-dimensional way. Alicona realizes this demand with their optional rotation unit, which rotates the work piece by 360˚. Employing InfiniteFocus Real3D the user will also measure geometric values like the undercut on thread flanks which cannot be measured by conventional means. Decisive angles like the front rake or flank angle are measured, as well as different diameters and the concentricity of the shaft. Deviations of shape with respect to a reference body are also automatically established. Due to the direct linkage to a CAD set of data, the user measures and visualizes deviations from the pre-defined CAD model. Measurements of two geometries or free-form surfaces bring to light wear and monitor compliance with tolerances. Says Martin Zeller, CEO of Bass, a manufacturer of high-precision threading tools about InfiniteFocus Real3D: “It was the possibility to measure roughness and form of our tools in high resolution with only one device that convinced us. We have been employing InfiniteFocus with Real3D since last year in our Research and Development.” This medium-sized company relies on innovative partners: “What pleases us about Alicona is their high innovative power, a trait with which we ourselves move within the market and which we expect of our partners. So, we’re happy to use Alicona’s products not only in R&D, but also in our production,” says Zeller.

Roughness Determines Surface Quality, Chip Flow and Mechanical Load Capacity

“Finally, we are able to measure the roughness of finely ground or polished surfaces.” With these words Thomas Kogler explains one of the numerous advantages that have surfaced since the introduction of InfiniteFocus for quality assurance. Kogler, a machinery technician with Amada, a leading manufacturer of band saw tools, saw machines and edging tools, is dealing with, amongst others, the optimization of band saw tools. Surface roughness is of prime importance here, being a decisive factor for adhesion, toughness and mechanical load capacity and in governing wear resistance. Kogler: ”We used to outsource our roughness measurements. This always meant high cost and took time, and was a source of uncertainty. Now we do our own measuring with InfiniteFocus and gain certainty by the high repeatability of the measurements.”

Surface roughness plays an important role for other features of quality, too. The smoother the surface, the better is the chip flow. This way, heating of the chips is reduced, which in turn means higher cutting performance. A high surface quality also minimizes the risk of fusing which, in the worst case, would lead to severely damaging of the tool and even rupture of the tool. Special micro treatment has the purpose of minimizing edge nicks and the danger of edge cracks. Surface roughness also governs layer adhesion in coating processes. Methods of surface smoothing are also used to level out unevenness and excess in roughness of a carrier substrate. Thus, a fast, precision-repeatable measurement of roughness with the possibility of leveling out is as governing a factor in quality assurance as roughness itself. By measuring the depth of roughness one can verify the effect and cost-efficiency of the different methods for surface smoothing, and judge processes of optimizing the surface. Amada appreciates yet another aspect in their daily work with the 3D measuring system: “InfiniteFocus is very easy to operate. For us, this is one of the important criteria, as there are several people working the system. Getting good results quickly and simply and without the necessity of prolonged training is a prerequisite,” Kogler says about operating the 3D measuring system.

Measuring Roughness Optically

To gain the highest surface quality with even the smallest component geometries requires high resolution measuring methods. This is why optical technologies are replacing more and more conventional methods like tactile measuring. The Focus-Variation technology for form and roughness measuring is increasingly sought after not only in the machining industry, due to its high vertical resolution and the vast field of application in a laboratory and in production. This method delivers more precise results at a shorter measuring time and thus enhances the efficiency of quality assurance. The user is able to measure the entire surface with up to 100 millions of measuring points, instead of only the profile of one single track. Also, measuring is done without any wear. The principle of optical, non-tactile form and roughness measuring prevents several types of inaccuracy which may occur with tactile measurements, where shape and size of the contact stylus tip largely influence the measuring result. Beside the 3D measuring results, InfiniteFocus will also give a true-color information for the surface, which, in turn, is of great advantage in wear analysis. The present draft of ISO 25178, for the first time standardizing optical measuring technologies, includes Focus-Variation.

Control, the Better Part of Confidence

Quality control is becoming a cost saving factor not only on the home turf. In goods receiving control, too, 3D surface control of the raw material is playing an important role. If, for example, the required roughness value of carbide metal should be known before processing, the product supplied can be checked by a suitable measurement of roughness quickly, simply and automatically. Easy automation of measuring allows efficient and reliable goods receiving control without much personnel involved. The user may also define several parameters, like elevations and depressions, which are then detected, measured and quantified automatically by InfiniteFocus. He thus checks the surface for faults or other deficiencies.