Fast topographic optical 3D imaging of objects

New approach for the real-time characterization of large or rapidly moving samples.

A team of experts from the University of Barcelona and the company Sensofar Tech have designed an innovative technology to obtain three-dimensional images of a study sample quickly, accurately and non-invasively. The new system is capable of characterizing the three-dimensional topography of an object with a speed and spatial resolution that exceeds the performance of current technological systems for identifying and recognizing objects in three dimensions. This system is a new development in the field of optical profilometry, a technique that is commonly applied in quality control and part inspection in various business sectors, from 3D-printed components to coronary prostheses (stents) or the identification of surface defects or roughness.

Optical profilometry is a discipline that measures the three-dimensional profile of objects using light. “It is a crucial methodology in areas such as quality control in industrial processes or, on a scientific scale, in the measurement of micro and nanostructures. Typically, the profile of a micrometric object is measured using a microscope, which obtains a collection of hundreds of images at different heights and planes of the object,” says Martí Duocastella. “This is a process, that involves scanning the sample plane by plane, an inherently slow process. In the new study, we present an innovation that is based on drastically reducing the acquisition time of this image collection.”

The new system is capable of operating at the micrometer scale on relatively large samples and in real time – up to sixty topographies per second. “Current technological systems can only achieve these speeds on very thin samples, or on large samples, but with low spatial resolution”, says Duocastella. “It is likely that our system can have a more significant impact because of its ability to characterize dynamic processes. So, thanks to our technology, the rapid movement of a small device – with a gas sensor – can be characterized in 3D, something that was impossible until now”.

To implement the new technology, “our idea is to intelligently interrogate the sample, similar to the way it is done in the Who’s Who game. So far, profiles are acquired by asking each plane if we had information: ‘Is the sample in plane 1?’, ‘Is it in plane 2?’, ‘In plane n?’ Each question involved making an image. In contrast, in our study we show that it is possible to interrogate different planes together: ‘Is the sample between plane 1 and plane 7?’. The result is that we achieved an enormous reduction in the number of images: if before we needed a hundred images, now we have enough with eight,” says the expert.

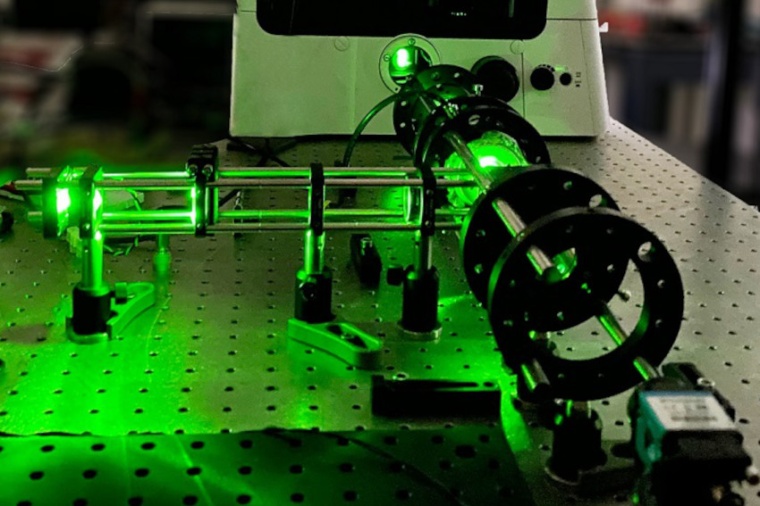

The new technique requires rapid scanning of the sample and synchronization of pulsed light of different durations. For fast scanning, an ultrafast liquid lens is used, which allows scanning thousands of times per second. For synchronization, an in-situ programmable gate array (FPGA) was used to generate the signal to pulse the light and capture the image from the camera. One of the most difficult phases was trying to achieve high data acquisition rates. “In this case, the signal received from the sample is weaker, and greater precision in the signals is needed. However, thanks to the work of PhD student Narcís Vilar, we were able to overcome these obstacles and successfully implement his new technology,” says Duocastella.

The main idea of the study has been to design a particular type of optical profilometer based on the projection of light patterns. “We are currently working on its implementation in other types of profilometers, including interference, polarization or confocal microscopes. We hope that by intelligently interrogating the sample, we can further improve current systems to characterize 3D samples with unprecedented accuracy and speed,” conclude the researchers. (Source: U. Barcelona)

Link: Dynamic Optical Systems Lab, Dept. of Applied Physics, Universitat de Barcelona, Barcelona, Spain • Sensofar Tech S.L, Terrassa, Spain