Colourful Spectrum of Image-processing

The change over to digital technology has recently become evident also in industrial image processing. In this area, three trends are unmistakable: the user has the choice between an embedded solution, a PC-based image processing system and an intelligent camera system. MaxxVision offers relevant, suitable cameras and components for all situations, as well as for all industries and applications – each individually modified to meet individual requirements and ideal for managing even very complex tasks in increasingly automated industrial processes.

Powerful, Robust, Easy to Use

One example of an advanced, embedded variant from the MaxxVision palette of solutions is the image-processing computer DSPC6000 Vision Box (Fig. 1) from its producer Strampe Systemelektronik. The Vision Box, which is performanceoptimised for processor-oriented applications and contains the TI signalprocessor family C64, processes high camera data rates and offers an extensive selection of interfaces (IEEE 1394, Camera Link, analog, 1-Gbit Ethernet, Fieldbus), as well as advanced software development tools, including libraries and application.

The flexible and modular stand-alone devices, with monitor and keyboard connections, are optimised for demanding image-processing tasks in every respect. They are robust and function without fans, which makes them maintenance-free and long-lived – ideal for applications in areas such as packaging, robotics, sorting, identification, assembly/ production, automotive and pharmaceutical. At any time they also are scalable for high-performance and real-time applications, and integrable into networks. Combined with Sony cameras, the Vision Box is a highly powerful system that offers the user many additional advantages.

These include the choice of camera for criteria such as size (ultra compact), interface (analogue, IEEE 1394, 1-Gbit Ethernet and Camera Link) and resolution (from VGA up to UXGA). Computational performance lies at 8,000 MIPS, which is significantly higher than similar PC solutions, and offers the possibility to cluster several computers together. If a machine is controlled via one of the Fieldbusses that is popular in the marketplace, the Vision Box will connect to it, regardless if it’s Profibus, CANopen, Interbus or other Fieldbusses. For connecting to the internet, the optional 1-Gbit-Ethernet interface provides rapid transmission of images and data.

Regarding programming, users can not only port their own C or C++ programs, but they can also implement their image processing libraries – like Halcon – with over 900 operators. Users can learn how to handle the development environments in training sessions and on-site briefings. In addition, programs in C from the PC world can be compiled. The advanced software tools run on both platforms. Connection to PCs occurs via standard Ethernet. The DSPC6000 Vision Box is always delivered as a ready-to-use, fully configured system, consisting of camera(s), Vision Box and development tools, as well as all interfaces – a situation which provides additional time and cost savings.

A sample program illustrates the quick start-up; the user can start immediately with the development of algorithms. When implementing additional systems, effort is not required for testing of new hardware components, driver updates or testing of configurations or system set-ups. In addition, OEM partners are guaranteed that they can order the Vision Box built identically for years to come. Even software updates take place quickly and easily. The application program is sent out via e-mail as its own file and is copied to a CompactFlash card, which then is placed in the Vision Box.

Go Digital

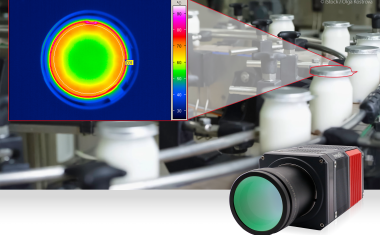

As Germany's first supplier of the machine-vision camera module XCD-V50 from Sony, MaxxVision strongly influenced the trend towards the digital interface, higher resolutions and frame rates and multi-camera systems. The following is an example of a PC-based image processing system. The first standard product of its kind brings all advantages of the IEEE 1394b standard to the machine-vision market. These advantages are: high speeds, scaleability and the special software and hardware compatibility with the serial network bus also known as FireWire. With the measurements 57 x 44 x 29 mm (LxHxW), the compact device is currently the smallest FireWire camera, which has double the bandwidth of the previous IEEE 1394a cameras with its 800 Mbit/s data rate.

It is also fast, easy to use and is installable into a small area. The monochrome CCD camera is based on Sony’s HAD technology and is equipped with a 1/3-inch image sensor utilising interline transfer (IT) technology. Because of the 14-bit output, 16,384 grey scales per pixel can be distinguished. The colour version of this highly compact camera series is the Sony XCD-V50CR (Fig. 2). This 1/3-inch Colour Raw camera distinguishes itself from others with its very high colour accuracy and proprietary colour transformation routines.

Smart Solutions

An additional, and concurrently the newest, variant on image-processing solutions are the intelligent Smart Cameras. This means that camera and processor become one, which is the case with Sony's new, intelligent Smart Camera (Fig. 3). The Sony XCI-SX1 integrates 10/100 Mbit Ethernet interfaces, USB 1.1 for keyboard and mouse, RS232C and an interface for commercially standard PC monitors. The 1.3-megapixel sensor delivers precise, monochrome SXGA images with 1280 x 1024 pixels and an image frequency of 15 fps (for SXGA) or 34 fps (for VGA). The system’s electronic heart is the AMD processor Geode GX533 at 400 MHz – combined with a CF storage card with 128 MB of space for the operating system and application programs (depending on the OS, expandable up to 2 GB), as well as a DDR-SDRAM main memory of an additional 128 MB.

With this new Smart Camera, developers can choose between the two standard operating systems Linux and Windows. As the recorded images can already be processed directly in the camera, the user has either pre-processed images or the resulting measured values available at the interface, depending on his or her wishes. “The new Smart Camera is a unique, ‘all-in-one’ solution for innovative, digital image processing and offers a high level of quality and functionality that is in demand from professional users in industry and science,” commented Sayed Soliman, Managing Director of MaxxVision GmbH of Stuttgart, Germany. “Thanks to CCD, higher resolution, the standard processor, open operating systems and a wide variety of industry- standard interfaces, the Sony XCI-SX1 allows direct processing of images in the camera or pre-processing them before transfer, which results in completely new possibilities such as distributed intelligence on complex testing tasks.” This differentiates the new generation of 'smart' image-processing cameras from Sony also from conventional solutions. Because of the keyboard, mouse and monitor interfaces on the Sony XCI-SX1, the user practically gets an entire PC in a compact format (measuring 55 x 55 x 110 mm).

User-friendliness in First Place

Compactness also means user-friendliness. And userfriendliness in the broadest sense is, Sayed Soliman is convinced, necessary for image- processing applications and is therefore a key objective of MaxxVision: “We look after the hardware and the software layers that lie between the hardware and application; we deliver continuity in our hardware, completeness in software, effective support and quick and uncomplicated serviceability. This allows our customers to concentrate fully on their applications and their own tasks.”

MaxxVision GmbH Tel. +49-(0)711-997 996 3 info@maxxvision.com www.maxxvision.com