“20 Years Ago We Believed that No One Needed More Infrared than a Single-Point Sensor”

Interview with Dr. Ulrich Kienitz, Managing Director of Optris

Two decades ago, Dr. Ulrich Kienitz established Optris, a company specialized in infrared measurement. On the occasion of this anniversary, the editorial team spoke to the company founder and owner.

How has technology and its technical applications in the field of infrared technology evolved?

Ulrich Kienitz: Nearly 150 years ago, the beginnings of infrared technology involved placing a small thermocouple in front of a curved mirror. Depending on what to aim for, this simple setup could reveal hotter objects, like ships in foggy weather. Infrared revealed the presence of something invisible. That is when the journey of infrared technology began.

In the 1920s, filament pyrometers were introduced as an optical method to measure temperatures. In simpler terms, you’d look through a lens and adjust the brightness of a lamp until it became indistinguishable from the object you were observing.

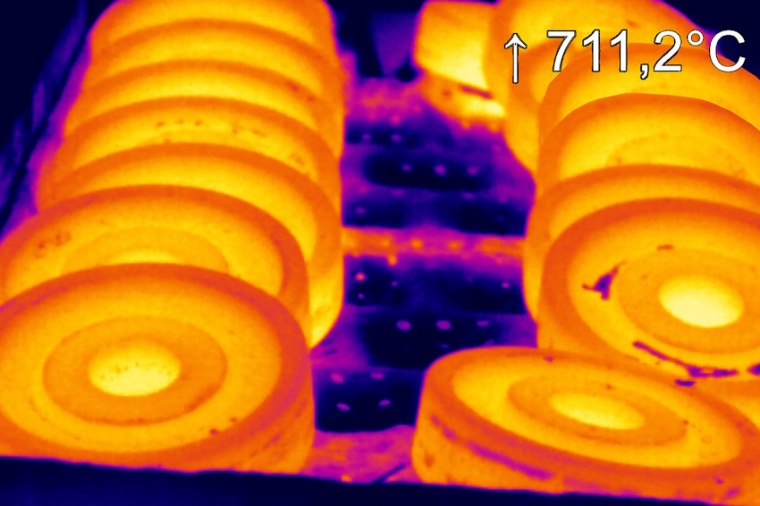

Over time, this technology has advanced significantly, with the development of sophisticated infrared pyrometers and cameras capable of detecting emitted infrared light from objects. Its applications are vast and varied today, ranging from industrial processes like steel manufacturing and food processing to medical diagnostics, building inspections, or environmental monitoring.

What do you consider the most important technological developments over the last 20 years since your company was established?

Kienitz: Advancements in semiconductors were the enablers. Semiconductor technologies have changed our entire lives. It started with computers, progressively shrinking in size, and at some point, they found their place in cell phones. But semiconductor technologies, and specifically, what is known as micro‐machining, have also made great progress in the infrared detectors world.

Today, thin bolometer layers achieve almost the same performance level as old camera systems with rotating prisms, filters, and liquid nitrogen-cooled detectors at lower cost. This was the real revolution because the price-performance ratio enabled its widespread utilization across various industries, including temperature measurement.

How important is the quality of the software in infrared cameras?

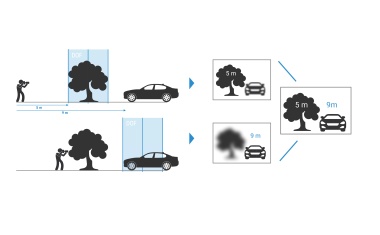

Kienitz: There are two parts of the software. One is the so‐called FPGA software, with processors working in parallel and running on the infrared camera. The challenge lies in processing a large amount of data from the detector and forwarding it quickly. The other part is that the image processing software converts the data to temperature information by considering the calibration and compensating for factors like emissivity.

The quality of software in infrared cameras and the image processing capabilities become increasingly critical as user-friendly interfaces, data analysis, remote monitoring, security, and seamless integration with other systems can directly impact camera performance and usability. That is a vital consideration when selecting an infrared camera for various applications.

How has the Optris product range changed over these last two decades?

Kienitz: We started with a single‐point sensor. It was composed of a small sensor head and a handheld device. Back then, we believed that no one needed more infrared. But things went differently. We expanded our product portfolio to cover various applications, especially in the metal, glass, and plastic processing sectors, and have developed special pyrometers. We developed thermal imaging cameras for industrial applications about five or six years after the company was founded. These cameras can more or less automatically detect the hot spot and feed temperature information into controls in an industrial process. While in the past, it was primarily employed as a device for research and development purposes. Nowadays, customers use these components as machine parts.

Which applications have stood out as particularly uncommon in the last twenty years?

Kienitz: Our cameras have been used on drones to inspect solar arrays, for example. This made it possible to discover which solar cells in a large grid were fine and which might be defective. The Fraunhofer Institute also funded applications to identify fawns in a meadow and rescue them before mowing. Many of our cameras were also used at airports during the Covid-19 pandemic since the cameras can be used to tell whether someone has a high body temperature.

Is there a particularly noteworthy product in your company, from a technological perspective, or one which you consider economically significant?

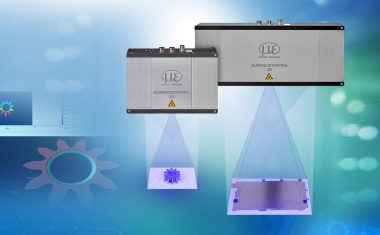

Kienitz: The technological breakthrough for us was that we were able to combine the point measurement technology business line with the camera technology one. This is the foundation of our very successful Xi product line. We now have devices that look like pyrometers – a tube with an output signal of 4–20 mA, for example – but operate as easy-to-use autonomous cameras. These devices record, evaluate images, and provide autonomously intelligent temperature information to the process controls.

Will cameras eventually replace all pyrometers?

Kienitz: I don't think so. We currently have approximately 820,000 pyrometers and approximately 30,000 cameras installed worldwide. Most machine manufacturers use our devices to detect if a critical stationary component is hot. Point sensors are sufficient for that. Also, metal, glass, or plastic applications often require different spectral ranges or two-color pyrometers, which still need to be available as cameras. Nevertheless, infrared imaging is constantly evolving. Due to the favorable price-performance ratio, individual sensors and cameras have become increasingly attractive for machine manufacturers.

What is manufactured at your company in Berlin and what is purchased?

Kienitz: We are a truly international company. With regard to sales, we export 75 percent of our production. We purchase a similar percentage of components and subcomponents or modules, some of which are manufactured in the United States and France. In contrast, injection-molded and plastic parts, including some electronic components, come from Asia. Production includes everything that is necessary and distinctive when it comes to infrared technology: final assembly, calibration, specific process steps measuring optical components that we assemble into lenses.

Are you offering any new products this year?

Kienitz: Our team of 20 research engineers continuously engage in developing novel products and platforms. This year we introduced a new ratio pyrometer with video capabilities. These are point measuring devices that measure across two different spectral ranges: the novelty lies in that high-resolution image circuits are now used for observation. These video circuits enable precise targeting of objects, facilitating accurate documentation of specific alarm events. They not only capture instances of elevated temperatures but also provide visual records of the affected workpiece during overheating. You can also observe the object in electronic format, granting you visibility into the system's focal point through the connected mobile phone. Additionally, the ratio pyrometer allows precise measurements even in cases of extremely dirty windows.

What does the future hold for infrared measurement technology over the next two decades?

Kienitz: We possess a distinct advantage as the physical unit temperature is the second most frequently measured parameter globally, trailing only behind time. Although we operate within various markets, our ability to swiftly adapt to emerging technological advancements and new markets remains unchanged. Our ability to adjust to new applications is notably fast. In 3D printing, our cameras oversee powder bed temperatures, while in solar cell production, we ensure product quality throughout the manufacturing process. In the manufacturing lines dedicated to electric mobility, our devices oversee the temperature of individual battery cells, providing preemptive notice for the replacement of individual components to proactively mitigate potential issues. Indeed, we are sure these trends will continue. In contexts where energy‐intensive and heat-related processes are essential, energy conservation becomes imperative, and our temperature sensors are a tool to gain more insights to optimize. Across the globe, our devices play a significant role in this regard.

Company

Optris GmbHFerdinand-Buisson-Str. 14

13127 Berlin

Germany

most read

Optical Metrology Technology: Focus-Variation and its Advanced Extensions

Basics of Measurement Technology

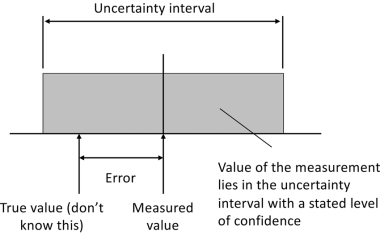

Measurement uncertainty in manufacturing: Understanding the basics

Why precise measurement results alone are not enough

Sensor Fusion in Outdoor Applications

AI-Driven Collision Warning System for Mobile Machinery