Check disordered objects quickly and precisely

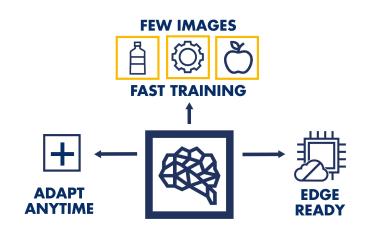

This not only makes quality control faster, but above all more precise and flexible. Ultimately, this is reflected in the higher quality of the tested products. No programming knowledge is necessary. With the help of neural networks, the module independently learns to identify, analyze and evaluate objects.

The user can train the neural networks for new products at any time without any programming effort. There is no limit to the number of features that the software can analyze using deep learning. This means that the test objects can be classified according to any number of properties. With the Deep Learning module, around 10 evaluations per second can be carried out on both black and white images and color images. The high precision of the evaluation is based on the HD image resolution of 1,280 x 720 pixels.

The software is available separately from Optometron. With the Vis-Vision complete package and the Optometron macro station, this becomes an intelligent QA workstation for complex image processing tasks.