3D-Daten für Cloud und Industrie 4.0

Das Exponat Connected Customization von Pepperl+Fuchs zeigt, wie mit Sensoren ein tiefenscharfes, mehrdimensionales Abbild der Realität erzeugt werden kann. Die kumulierten Messdaten stehen in einem Standard-Datenformat global zur Verfügung, sodass sie für Anwendungen im Sinne von Industrie 4.0 und IoT uneingeschränkt genutzt werden.

Die ursprüngliche Idee für die hochauflösende 3D-Vermessung stammt aus dem Flugzeugbau. Dort wird sie mit Laserscannern eingesetzt, um zum Beispiel Bauteile präzise miteinander zu verbinden. In einem Messe-Exponat baut Pepperl+Fuchs das Potenzial dieser Technologie für Anwendungen im Sinne von Industrie 4.0 aus: mit einer weiteren Messwert-Dimension und Daten im Standardformat, die im Internet hinterlegt sind und per App genutzt werden können. Horizontal und vertikal vernetzt stehen sie für durchgängiges Engineering sowie für automatisierte Produktionsabläufe ab Stückzahl 1 zur Verfügung.

Joint Venture mit Lufthansa

2018 gründeten Lufthansa Technik und Pepperl+Fuchs gemeinsam in Hamburg das Joint Venture 3d.aero. Ziel ist es, neue Automatisierungslösungen für die Flugzeugindustrie zu entwickeln und die Digitalisierung der Fertigung voranzutreiben. Anwendungen für optische Messgeräte stehen dabei unter anderem im Mittelpunkt. So können zum Beispiel mehrere Geräte mit optischen Laufzeitmessverfahren kombiniert werden, um 3D-Abbilder von Bauteilen und ihren Einbauorten zu erstellen und anhand dieser Daten die hochpräzise automatisierte Montage zu ermöglichen. Die gleiche Technologie kann dazu dienen, Lackierroboter zu steuern oder die Fahrgastbrücke vor der Kabinentür zu positionieren. Wegen des gewölbten Rumpfes ist deren präzises Heranfahren keine einfache Aufgabe. Zugleich müssen aufgrund der strengen Sicherheitsvorschriften auch kleine Kollisionen zuverlässig verhindert werden.

Aus der Erfahrung mit solchen Anwendungen stammte der ursprüngliche Impuls, die 3D-Erfassung von Objekten im Sinne der Industrie 4.0 weiterzuführen und ihre technischen Möglichkeiten, auch auf der Ebene der Information, umfassend auszureizen. Als Testversion entstand das Messe-Exponat Connected Customization, bei dem sich Messebesucher sozusagen als Objekt zur Verfügung stellen. Dessen Konturen werden mit sechs an vertikalen Linearachsen montierten LiDAR-Sensoren aus der R2000-Serie erfasst. Jeder einzelne Sensor liefert einen 3D-Scan, die Messdaten aller sechs Einheiten werden dann zu einer 3D-Punktewolke zusammen gesetzt. Auf diese Weise werden Abschattungen wirksam vermieden.

Puls plus Rotation

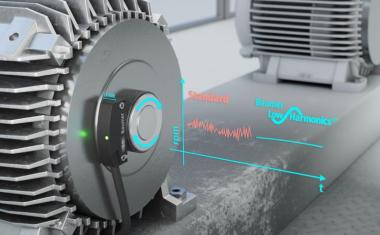

Die R2000-Sensoren arbeiten nach dem Lichtlaufzeit-Verfahren mit Pulse Ranging Technology (PRT). Einer Laserdiode sendet hochenergetische Lichtimpulse, die vom Objekt reflektiert werden. Aus der Zeit, die das Licht zum Objekt und wieder zurück benötigt, berechnet der Sensor die Entfernung. Dank der Pulse Ranging Technologie arbeitet das Verfahren auch stabil bei Fremdlicht und auf dunklen, schlecht reflektierenden Zielobjekten. Der R2000 liefert 250.000 Entfernungs-Messwerte pro Sekunde.

Die Vorteile der Pulse Ranging Technology werden durch die Rotation des 360°-Messmoduls ergänzt. Dieses kreist auf einer starren Achse und erzeugt eine gleichmäßige Scanebene praktisch ohne Winkelabweichung. So erreicht der Sensor eine vollständige Rundumsicht mit einer Winkelauflösung von bis zu 0,07°, eine Drehfrequenz bis 30Hz und Messraten bis 54kHz. Damit erkennt er zuverlässig auch bewegte Objekte und sehr kleine Gegenstände. R2000-Sensoren werden häufig für Kollisionsschutz, Bereichsüberwachung bei fahrerlosen Transportfahrzeugen oder für das Erkennen von Objekten dicht an einer Oberfläche verwendet. Durch Bewegung der Sensoren und Kombination mehrerer Geräte können präzise Abbilder dreidimensionaler Konturen ohne Schattenwurf hergestellt werden.

Die vierte Dimension

Vergangenes Jahr wurde das Exponat erweitert, indem neben den Sensoren zusätzlich Farbkameras montiert wurden. Ihre Aufnahmen ergänzen die Entfernungsdaten um die Bildinformation aus Helligkeit, Farbe und Kontrast. Diese Daten stehen beispielhaft für eine vierte Dimension, die dem 3D-Abbild hinzugefügt werden und einen Mehrwert für die Erledigung unterschiedlicher Aufgaben schaffen kann. Statt Kameras könnten auch andere Geräte wie Temperaturscanner hinzukommen. Mit ihnen ließe sich etwa ein hochaufgelöstes Temperaturprofil erstellen oder der Temperaturverlauf verfolgen.

Für die exakte Zuordnung solcher zusätzlicher Messwerte zu den Konturpunkten ist eine präzise 3D-Kalibrierung aller Sensoren erforderlich. Nur so entsteht ein aussagekräftiges Gesamtbild.

Die Positions- und Bilddaten werden zu einer Punktewolke zusammengefasst, dabei wird das Standardformat PCD (Point Cloud Data) verwendet. Damit ist sichergestellt, dass die Daten mit frei verfügbaren Werkzeugen weiter verarbeitet werden können.

Die von Connected Customization generierten PCD-Datensätze stehen autorisierten Benutzern in der NeoNeon-Cloud des Pepperl+Fuchs-Tochterunternehmens Neoception weltweit zur Verfügung.

Sofortige Nutzung

Das Messe-Exponat demonstriert den globalen Datenzugriff und eine erste Nutzung: Der Besucher kann sein 3D-Abbild sofort auf seinem Smartphone betrachten, die Visualisierung übernimmt eine Augmented-Reality-App, die aus den App-Stores abgerufen werden kann. Für den Zugang zu den Daten wird ein QR-Code gescannt, mit der App scannt man anschließend den Positionsmarker des Exponats. Wer sich auf das Experiment einlässt, kann sich auf dem eigenen Mobilgerät in 3D und Farbe von allen Seiten betrachten und bekommt ein mit seinem Abbild auf der Titelseite personalisiertes Messemagazin ausgehändigt. Es besteht auch die Möglichkeit, sich als 3D-Modell in Plexiglas zu produzieren.

Das Exponat Connected Customization verdeutlicht drei wesentlichen Aspekte von Industrie 4.0:

- Durch horizontale Integration einer Vielzahl von Komponenten wird eine umfassendes virtuelles Abbild der Realität geschaffen.

- Die vertikale Vernetzung stellt die Daten über das Internet einer breiten Basis zur Nutzung bereit.

- Die Anforderungen an ein durchgängiges Engineering ohne Medienbrüche werden durch die Verwendung von Standard-Datenformaten erfüllt.

Die mit Connected Customization gezeigten Technologien bieten abgestimmte Lösungen für individualsierte Prüf- oder Produktionsprozesse bis hinunter zu Losgröße 1.

Anbieter

Pepperl+Fuchs SELilienthalstrasse 200

68307 Mannheim

Deutschland

Meist gelesen

AR-gestützte Qualitätskontrolle von Kranteilen

Bauteilprüfung mit Augmented Reality direkt in der Fertigung

Kunststoffe effizient recyceln

Hyperspektrale Kameras erhöhen Sortiergenauigkeit von Kunststoff-Flakes

Warum Autovimation der Exaktera-Gruppe beitrat

Peter Neuhaus erläutert die Beweggründe für den Verkauf von Autovimation an Exaktera. Im Vordergrund stand die strategische Weiterentwicklung durch internationale Vertriebsstrukturen und zusätzliche Marketingressourcen.

Im Schlamm ruht sich ein großes Nilpferd aus

Virtuelle Video-Safaris für blinde und sehbehinderte Personen

Shack-Hartmann-Sensor für Filtermessungen im Transmissionsband

Die Präzision optischer Anwendungen steigt, ebenso die Qualitätsanforderungen. Hersteller müssen Produktion und Messtechnik anpasen. Ein Shack-Hartmann-System bietet eine Lösung mit hoher Genauigkeit und Wiederholbarkeit