3D-printing of microscale photonic lantern multiplexers

21.06.2024 - New approach opens opportunities for spatial mode multiplexing.

Optical waves propagating through air or multimode fiber can be patterned or decomposed using orthogonal spatial modes, with far-ranging applications in imaging, communication, and directed energy. Yet the systems that perform these wavefront manipulations are cumbersome and large, restricting their utilization to high-end applications. The development of a “Free-Standing Microscale Photonic Lantern Spatial Mode (De-)Multiplexer using 3D Nanoprinting“, as revealed by a recent study, marks a significant advancement in photonic technology.

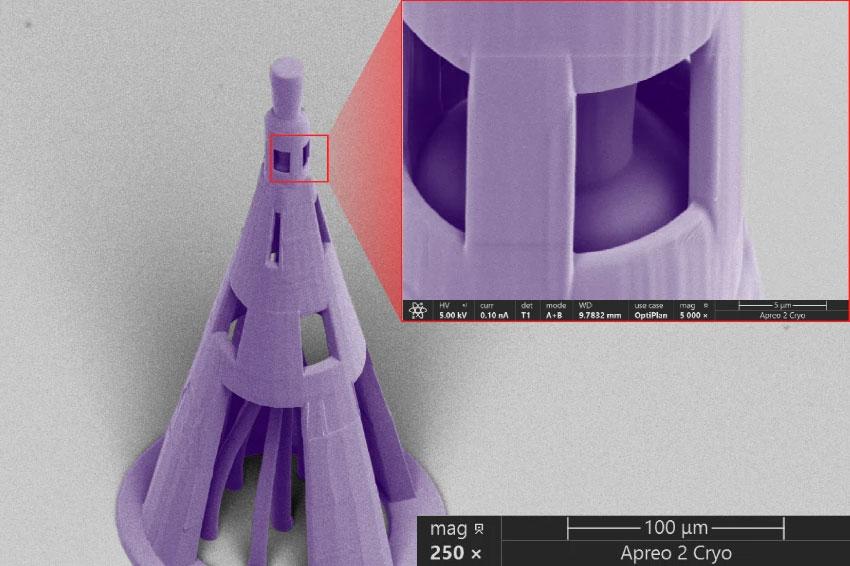

This spatial multiplexer, characterized by its compactness, minimal footprint, and ability to directly print on, and adhere to, photonic circuits, optical fibers, and optoelectronic elements as lasers and photodetectors, opens new opportunities in system integration and adoption of the technology in future high-capacity communication systems and demanding imaging modalities. The work of Yoav Dana, Dan Marom and his team at the Hebrew University of Jerusalem, in partnership with scientists from Nokia Bell Labs, resulted in the development and demonstration of the new microscale photonic lantern. The device was fabricated by a 3D nano-printing technique utilizing direct laser writing, applied directly onto an optical fiber tip.

Photonic lantern devices convert between optical waves containing a superposition of modes or distorted wavefronts and array of separated single-mode optical signals. The technology stands out as a promising contender to enable space division multiplexing (SDM) in high-capacity future optical communication networks, as well as in imaging and other applications requiring the spatial manipulation of optical waves.

Harnessing the capabilities of 3D nano-printing and employing high-index contrast waveguides, the researchers have developed a compact and versatile device that can be printed onto nearly any solid platform with fine accuracy and high fidelity, enabling its seamless integration into a variety of technological contexts. The approx. 100 micrometer scale device stands in large contrast to traditional photonic lanterns based on weakly guiding waveguides that are millimeters to centimeters long, making integration with micro-scale photonic systems very challenging.

“The development of this “Free-Standing Microscale Photonic Lantern Spatial Mode (De-)Multiplexer” represents a significant advancement in our ability to enable and adopt spatial multiplexing for diverse optical systems and applications,” said Dan Marom. “This breakthrough makes space division multiplexing technology much more accessible and amenable towards integration, opening up new possibilities for optical communication and imaging applications, to name a few.”

The researchers have presented the device design using genetic algorithms, fabrication onto a fiber tip, and characterization of a six-mode mixing, 375 microns long photonic lantern capable of converting between six single-mode inputs into a single six-mode waveguide. Despite its compact size, the device exhibits low insertion loss (-2.6 dB), low wavelength sensitivity and low polarization and mode-dependent losses of -0.2 dB and -4.4 dB, respectively. (Source: HUJI)